Decorative Embossed Stainless Steel Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specifications about stainless steel sheet

Commodity | Professional 430 201 202 304 304l 316 316l 321 310s 309s 904l stainless steel sheet |

Grade | 201,202,304,304L,316,316L,310S,309S,321,301,310,410,420,430,904L |

Brand | TISCO ,BAOSTEEL,POSCO,JISCO,LISCO |

Certification | SGS,BV,IQI,TUV,ISO,etc |

Thickness | 0.2mm-150mm |

Width | 1000,1219,1250,1500mm, or as your requirements |

Length | 2000,2438,2500,3000,6000mm, or as your requirements |

Surface | No.1, 2B, BA, 8K Mirror, Hairline,satin, Embossed,brush,No.4,HL,matt,pvc film,laser film. |

Standard | ASTM,AISI,SUS,JIS,EN,DIN,GB, ASME,etc |

Delivery time | 5-7 days after confirming the order |

MOQ | 1 Ton |

Advantages | Showing the splendor of your quality, wearresistant as well , strong corrosion resistance and decorative effect, durable and beautiful in good taste. |

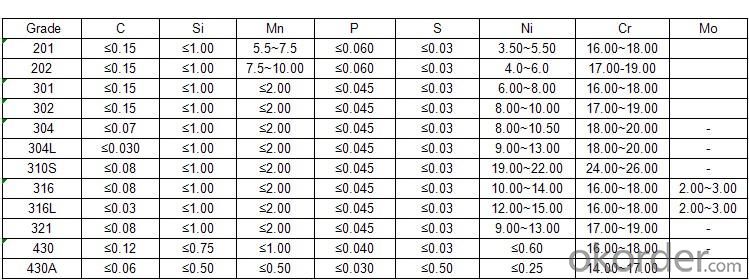

2. Chemical Composition about stainless steel sheet

- Q: What is the bending strength of stainless steel sheets?

- The bending strength of stainless steel sheets can vary depending on the specific grade and thickness of the sheet. However, stainless steel is generally known for its high strength and rigidity, making it suitable for various applications that require strong and durable materials.

- Q: Can stainless steel sheets be used for decorative wall panels?

- Yes, stainless steel sheets can be used for decorative wall panels. Stainless steel is a versatile material that can be easily shaped and manipulated to create various designs and patterns. It is known for its sleek and modern appearance, making it a popular choice for contemporary and industrial-style interiors. Stainless steel sheets are available in different finishes, such as brushed, mirrored, or textured, allowing for further customization and adding visual interest to the wall panels. Additionally, stainless steel is resistant to corrosion, durable, and easy to clean, making it suitable for high-traffic areas or environments prone to moisture or humidity. Overall, stainless steel sheets can provide a stylish and functional solution for decorative wall panels.

- Q: How are stainless steel sheets produced?

- Stainless steel sheets are produced through a process called hot rolling, where stainless steel ingots are heated and passed through a series of rollers to reduce their thickness and improve their surface finish. This continuous rolling process creates long sheets of stainless steel, which are then cooled and cut into desired lengths. The sheets may undergo further processing, such as annealing or surface treatment, before being packaged and shipped for various applications.

- Q: What are the advantages of using stainless steel sheets?

- Using stainless steel sheets in various applications offers several benefits. First and foremost, stainless steel is renowned for its outstanding resistance to corrosion. It is highly effective in preventing rust and stains, making it an ideal option for environments where moisture and corrosive substances are present. This exceptional durability ensures that stainless steel sheets maintain their aesthetic appeal and structural integrity over time. Furthermore, stainless steel is exceptionally strong and durable. It possesses a high tensile strength, enabling it to withstand heavy loads and resist deformation. This makes stainless steel sheets perfect for applications that require robustness, such as construction, automotive, and industrial projects. Additionally, stainless steel is sanitary and easy to clean. Its non-porous surface prevents the growth of bacteria and other microorganisms, making it a popular choice for food processing equipment, medical tools, and healthcare facilities. Moreover, stainless steel sheets are simple to maintain, as they can be easily wiped clean or sterilized without causing any damage to the material. Moreover, stainless steel sheets offer both versatility and aesthetic appeal. They feature a sleek and modern appearance that can enhance the visual appeal of architectural designs, interior decorations, and kitchen appliances. With a variety of finishes available, including brushed, mirror, or textured, stainless steel sheets can be customized to suit specific design preferences. Lastly, stainless steel is an environmentally friendly material. It is 100% recyclable, meaning it can be reused and repurposed without any loss in quality or performance. This makes stainless steel sheets a sustainable choice, reducing the necessity for new raw materials and minimizing waste. In conclusion, the benefits of using stainless steel sheets include exceptional corrosion resistance, strength and durability, hygienic properties, aesthetic appeal, and environmental sustainability. These characteristics make stainless steel sheets a versatile and dependable choice for a wide range of applications.

- Q: What do stainless steel 304 industrial surfaces refer to?

- The industrial surface is the ordinary pickling surface, which is treated by the last pickling process. Is the kind of white surface that you see at ordinary times. The bright surface of life is the surface of which is further polished or annealed.

- Q: Can stainless steel sheets be cut to size?

- Certainly, it is possible to cut stainless steel sheets to the desired size. These sheets are incredibly versatile and can be readily tailored to meet specific dimensions and needs. Multiple cutting techniques, including plasma cutting, laser cutting, or waterjet cutting, can be utilized for this purpose. These methods guarantee precise and accurate cuts, maintaining the integrity of the stainless steel sheet while achieving the desired size. Moreover, stainless steel's remarkable durability and resistance to corrosion make it an ideal choice for applications involving cutting and shaping.

- Q: What are the benefits of using embossed stainless steel sheets in elevator doors?

- Embossed stainless steel sheets offer several benefits for elevator doors. Firstly, the embossed pattern adds a touch of elegance and sophistication, enhancing the overall aesthetic appeal of the elevator. Additionally, the embossed texture helps to improve grip and prevent slipping, ensuring safety for passengers. Furthermore, stainless steel is highly durable and resistant to corrosion, making it an ideal material for elevator doors that are subject to constant use and exposure to various environmental factors. Lastly, stainless steel sheets are easy to clean and maintain, saving time and effort in the long run.

- Q: Can stainless steel sheets be used for water pipelines?

- Yes, stainless steel sheets can be used for water pipelines. Stainless steel is highly resistant to corrosion and has excellent strength, making it a suitable material for water pipelines that require durability and longevity. Additionally, stainless steel's smooth surface helps to maintain water flow efficiency and prevent contamination.

- Q: Are stainless steel sheets suitable for decorative purposes?

- Stainless steel sheets are a perfect choice for decorative purposes. They possess a sleek and contemporary appearance, which adds a touch of elegance and sophistication to any given space. The smooth and reflective surface of stainless steel creates a visually pleasing aesthetic that enhances the overall look and feel of a room. Furthermore, stainless steel is incredibly durable and corrosion-resistant, making it an excellent long-term option for decorative use. The versatility of stainless steel sheets allows them to be utilized in various decorative forms, including wall panels, backsplashes, countertops, and even furniture. Regardless of whether they are used in residential or commercial settings, stainless steel sheets can be employed to create remarkable and attention-grabbing decorative elements that perfectly complement any interior design style.

- Q: How do you determine the best thickness of stainless steel sheet for a specific application?

- To determine the best thickness of stainless steel sheet for a specific application, several factors need to be considered. These factors include the required strength, durability, and corrosion resistance for the application, as well as any weight or cost limitations. It is also crucial to analyze the mechanical and chemical properties of the stainless steel and evaluate its compatibility with the intended environment and potential stress factors. Engineering calculations, industry standards, and consultation with material experts or engineers can help in making an informed decision about the appropriate thickness for the stainless steel sheet.

Send your message to us

Decorative Embossed Stainless Steel Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords