Stainless Steel Sheet Food with Cheap Pricing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot sale stainless steel sheet 201/202/304/304l/316/316l/430 in china alibaba

Product Description

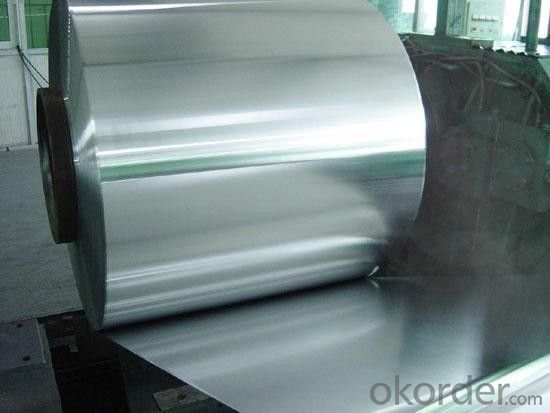

Stainless steel sheet Detailed introduction

Description | steel sheet,hot rolled steel sheet,cold rolled steel sheet, steel sheet,sheet,steel plate |

Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

Application | Steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. |

Packaging | Standard export sea-worthy packing |

Delivery time | 10-30 days |

Quality | No.1 |

Productivity | 500 tons/Day |

Note | Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured. |

Contacts | If you have any question,please feel free contact me. |

Stainless steel sheet surface finish characteristics

Surface finish | Characteristics and application |

2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

No.1 | Polished with abrasive belt of grit#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

No.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria, but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc. |

8K | The product have excellent brightness and prefer reflexivity can to be the mirror. |

Application :

•Escalator, Elevator, Doors

•Furniture

•Production tools, Kitchen appliances, freezers, cold rooms

•Auto Parts

•Machinery and Packaging

•Equipment and Medical devices

•Transport system

Product Details:

Sandard Seaworth Packing(wooden packing with water proof paper)

If you have any question about stainless steel sheets,donot forget to sending the email to Us! You will get the competitive Price and have a very good experience about the Buying Process! CNBM International Corporation is always your trustful friend!

- Q: Are stainless steel sheets suitable for food processing or medical applications?

- Stainless steel sheets are ideal for food processing and medical applications as they possess a range of beneficial properties. Firstly, their resistance to corrosion makes them perfect for environments where cleanliness and hygiene are paramount, such as food processing plants and medical facilities. Moreover, stainless steel is a non-porous material, meaning it does not absorb bacteria, germs, or odors. Consequently, it is effortless to clean and maintain high levels of sanitation, a crucial factor in both food processing and medical settings, where reducing contamination is vital. Furthermore, stainless steel boasts excellent strength and durability, enabling it to withstand harsh conditions, heavy usage, and frequent cleaning without deteriorating. This reliability and longevity make stainless steel sheets an excellent choice for these demanding applications. Additionally, stainless steel is non-reactive with both food and many medical substances, ensuring that no harmful chemicals or contaminants leach into the processed products or the patients being treated. This feature is essential for upholding the safety and integrity of both food and medical materials. To summarize, stainless steel sheets are highly suitable for food processing and medical applications due to their corrosion resistance, non-porous nature, strength, durability, and non-reactive properties. By choosing stainless steel, the highest standards of cleanliness, hygiene, and safety can be maintained in these industries.

- Q: What is the maximum operating temperature for stainless steel sheets?

- The maximum operating temperature for stainless steel sheets can vary depending on the grade of stainless steel, but it typically ranges between 1500-1650°F (816-899°C).

- Q: Can stainless steel sheets be bent or formed?

- Yes, stainless steel sheets can be bent or formed. Stainless steel is a highly versatile material that can be easily manipulated into various shapes and forms. It has excellent ductility, which allows it to be bent, stretched, or formed without cracking or breaking. However, the degree to which stainless steel sheets can be bent or formed depends on the thickness and grade of the material. Thinner sheets are generally more malleable and easier to bend, while thicker sheets may require more force or specialized equipment for shaping. Additionally, certain stainless steel alloys may have specific limitations on their formability. Overall, stainless steel sheets can be bent or formed to meet specific design requirements, making them a popular choice for a wide range of applications in industries such as construction, automotive, and manufacturing.

- Q: Can stainless steel sheets be used for medical sterilization equipment?

- Yes, stainless steel sheets can be used for medical sterilization equipment. Stainless steel is commonly used in the healthcare industry due to its excellent corrosion resistance, durability, and ease of cleaning. It can withstand high temperatures and harsh cleaning agents used in sterilization processes, making it an ideal material for medical equipment that requires frequent sterilization.

- Q: How do you remove water stains from stainless steel sheets?

- To remove water stains from stainless steel sheets, you can try using vinegar or lemon juice. Apply either of these ingredients onto the stained area, let it sit for a few minutes, and then gently rub the stain with a soft cloth or sponge. Rinse the area with water and dry it thoroughly. If the stain persists, you can also consider using a stainless steel cleaner specifically designed for removing water stains.

- Q: Can stainless steel sheets be used for kitchen countertops?

- Absolutely, kitchen countertops can indeed be made from stainless steel sheets. The reason stainless steel is such a widely favored option for kitchen countertops is because of its exceptional durability, heat resistance, and hygienic qualities. It possesses a remarkable ability to ward off stains, corrosion, and rust, rendering it an ideal material for high-traffic areas, such as the kitchen. Moreover, stainless steel countertops are effortlessly cleaned and maintained, making them an extremely practical choice for bustling kitchens. Furthermore, the inclusion of stainless steel lends a polished and cutting-edge appearance to the kitchen, rendering it an exceedingly popular choice for both contemporary and industrial-style kitchens.

- Q: What is the strain hardening exponent of stainless steel sheets?

- The ability of stainless steel sheets to increase their strength and hardness as they undergo plastic deformation or strain is referred to as the strain hardening exponent. This exponent measures how the stress-strain curve of the material changes as deformation increases. Typically, stainless steel sheets have a strain hardening exponent ranging from 0.2 to 0.4. This value signifies that the material experiences a moderate increase in strength and hardness when subjected to plastic deformation. A higher strain hardening exponent indicates a greater resistance to deformation and better ability to maintain its shape under external forces. The strain hardening exponent plays a crucial role in engineering applications as it impacts the material's formability, ductility, and resistance to deformation. Materials with higher strain hardening exponents are preferred in industrial processes like sheet metal forming or cold working as they offer enhanced work-hardening properties. However, excessively high strain hardening exponents can lead to issues such as cracking or material failure. It is important to acknowledge that the strain hardening exponent can vary depending on the specific grade and composition of the stainless steel alloy. Different stainless steel alloys may exhibit distinct strain hardening behaviors, necessitating consideration of the material's properties and specifications when determining the strain hardening exponent for a particular stainless steel sheet.

- Q: What is the fatigue strength of stainless steel sheets?

- The fatigue strength of stainless steel sheets can vary depending on various factors such as the specific grade of stainless steel, the manufacturing process, the surface finish, and the testing conditions. Generally, stainless steel sheets exhibit high fatigue strength due to their inherent properties, such as the ability to withstand cyclic loading and resistance to corrosion. The fatigue strength of stainless steel sheets is typically expressed in terms of stress amplitude (σa) or stress range (σr) that the material can withstand for a specific number of cycles before failure. It is often determined through fatigue testing, which involves subjecting the material to repeated cyclic loading until failure occurs. The number of cycles required to cause failure is known as the fatigue life. Different grades of stainless steel have different fatigue strengths, with higher grades typically exhibiting higher fatigue resistance. For instance, austenitic stainless steels such as 304 and 316 have excellent fatigue strength and are commonly used in applications where cyclic loading is prevalent, such as structural components and automotive parts. The fatigue strength of stainless steel sheets can also be influenced by surface finish. Poor surface conditions, such as scratches, notches, or roughness, can act as stress concentrators and reduce the fatigue strength. Therefore, it is important to ensure that stainless steel sheets have a smooth and defect-free surface to maximize their fatigue resistance. Moreover, the fatigue strength of stainless steel sheets can be affected by environmental factors such as temperature, humidity, and corrosive media. Elevated temperatures and aggressive environments can reduce the fatigue life of stainless steel, so it is crucial to consider these factors when designing for fatigue resistance. In conclusion, the fatigue strength of stainless steel sheets is generally high due to their inherent properties. However, it can vary depending on factors such as grade, surface finish, and environmental conditions. Conducting fatigue testing and considering these factors during the design process can help ensure the optimal performance and durability of stainless steel sheets in cyclic loading applications.

- Q: Stainless steel thermos cup 304 and 201 material what is the difference?

- 304 stainless steel toughness better: 201 stainless steel material is relatively hard, with a little steel, relatively easy to crack. The 304 stainless steel insulation Cup because it contains nickel, it is not rusty, and 304 stainless steel more toughness, fatigue resistance is much better than 201.

- Q: What are the different types of textured finishes available for stainless steel sheets?

- There are several different types of textured finishes available for stainless steel sheets, each offering a unique aesthetic appeal and functional benefits. Some of the most common textured finishes include: 1. Brushed Finish: This is the most widely used textured finish for stainless steel sheets. It is achieved through a process of brushing the surface with abrasive materials, creating a distinctive pattern of parallel lines. The brushed finish provides a smooth and elegant appearance while also masking scratches and fingerprints. 2. Embossed Finish: In this type of textured finish, a pattern is stamped onto the stainless steel sheet, creating a raised design. Embossed finishes can range from simple patterns like diamonds or squares to more complex designs. This finish adds depth and visual interest to the metal surface. 3. Bead Blast Finish: This finish is achieved by propelling fine glass beads or ceramic particles onto the stainless steel sheet at high pressure. It creates a uniform matte appearance with a slightly rough texture. Bead blasting is often used for decorative purposes, as it can give stainless steel a unique and contemporary look. 4. Linen Finish: Also known as a cross-hatch finish, the linen finish features a pattern of fine parallel lines that intersect, resembling the texture of linen fabric. This finish is achieved through a process of mechanical rolling or brushing. It provides a textured surface that is both visually appealing and resistant to scratches. 5. Satin Finish: Similar to brushed finish, the satin finish is achieved by brushing the stainless steel sheet with abrasive materials. However, the satin finish has a smoother appearance with a less pronounced pattern of parallel lines. It offers a subtle shine and a refined look, making it a popular choice for architectural and decorative applications. 6. Hammered Finish: This textured finish is created by pounding the stainless steel sheet with a ball-peen hammer or a similar tool. The result is a surface with a unique hammered pattern that adds a rustic and artisanal touch to the metal. Hammered finishes are commonly used in interior design and decorative applications. Overall, the choice of textured finish for stainless steel sheets depends on the desired aesthetic, functionality, and application. Each finish has its own distinct appearance and can enhance the visual appeal of stainless steel while also providing additional benefits such as scratch resistance and fingerprint hiding.

Send your message to us

Stainless Steel Sheet Food with Cheap Pricing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords