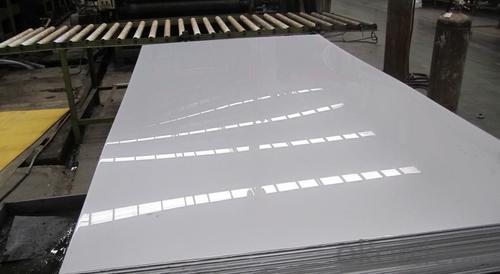

Stainless Steel sheet and Plate in Cheap price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of stainless steel

304 stainless Steel Plate

stainless steel plate,steel sheet,steel plate

Standard: ASTM,GB,DIN,JIS,ISO,EN,etc.

TISCO stainless Steel Plate 304/NO.1 finished

stainless steel plate,steel sheet,steel plate

Standard: ASTM,GB,DIN,JIS,ISO,EN,etc.

Delivery short and low cost advantage.

Description of stainless steel:

stainless steel plate,hot rolled stainless steel plate,cold rolled stainless steel plate,stainless steel sheet,steel sheet,sheet

Material of stainless steel:

304,304L,309S,310S,316,316L,316Ti,317L,317L,321,347H,409,409L,410S,420,430,201,202,etc.

Thickness of stainless steel:

From 0.3mm to 100mm

Width of stainless steel:

1000mm,1219mm,1250mm,1500mm,1800mm,2200mm,2500mm or as your requirement

Length of stainless steel:

2000mm,2438mm,2500mm,6000mm,6096mm or as your requirement

Application of stainless steel:

Stainless steel plate applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. Our company has cooperative relation between the domestic agents. Stainless steel plate can be made accordingto the customers requirements. Fasten delivery. Quality assured.Welcome to order more.

Contacts

If you have any question,please feel free to contact us.

- Q: How do I prevent intergranular corrosion on stainless steel sheets?

- To prevent intergranular corrosion on stainless steel sheets, there are several measures you can take: 1. Choose the right stainless steel grade: Use stainless steel grades that are specifically resistant to intergranular corrosion, such as 304L, 316L, or 321. These grades have lower carbon content, which helps in minimizing the formation of chromium carbides at grain boundaries. 2. Heat treatment: After fabrication or welding, subject the stainless steel sheets to a solution annealing or post-weld heat treatment process. This heat treatment eliminates the chromium carbides that may have formed during welding or high-temperature processing, preventing intergranular corrosion. 3. Avoid exposure to high temperatures: Stainless steel sheets should not be exposed to temperatures between 450 to 850 degrees Celsius (842 to 1562 degrees Fahrenheit) for extended periods. If exposed, chromium carbides may form at the grain boundaries, making the stainless steel susceptible to intergranular corrosion. 4. Use proper welding techniques: When welding stainless steel sheets, use low heat input and minimize the time the material is exposed to high temperatures. This helps in reducing the formation of chromium carbides and preserves the corrosion resistance of the stainless steel. 5. Pickling and passivation: After fabrication or welding, ensure that the stainless steel sheets are properly pickled and passivated. Pickling removes any contaminants on the surface, while passivation forms a protective oxide layer that prevents intergranular corrosion. 6. Regular maintenance and cleaning: Keep the stainless steel sheets clean and free from contaminants that could potentially cause corrosion. Regularly clean the surfaces with mild detergents and avoid using harsh chemicals or abrasive materials that may damage the protective oxide layer. By following these preventative measures, you can significantly reduce the risk of intergranular corrosion on stainless steel sheets and maintain their corrosion resistance properties for a longer lifespan.

- Q: Are stainless steel sheets resistant to stress corrosion cracking?

- Yes, stainless steel sheets are generally resistant to stress corrosion cracking. This is due to their high chromium and nickel content, which provides excellent corrosion resistance properties. Stress corrosion cracking is a type of corrosion that occurs under tensile stress in a corrosive environment. Stainless steel sheets are alloyed with elements that form a passive protective layer on the surface, making them highly resistant to corrosion and preventing stress corrosion cracking. However, it is important to note that the resistance to stress corrosion cracking can vary depending on the specific grade of stainless steel and the environmental conditions it is exposed to. Therefore, it is recommended to consult the manufacturer or refer to corrosion resistance charts to ensure the appropriate stainless steel grade is selected for specific applications.

- Q: Can stainless steel sheets be recycled after use?

- Stainless steel sheets are indeed recyclable once they have served their purpose. This material is highly recyclable and possesses qualities that make it perfectly suited for recycling. The process of recycling stainless steel entails melting the sheets to extract the raw materials, which can subsequently be utilized in manufacturing new stainless steel products. By recycling stainless steel, not only are we conserving natural resources, but we are also reducing energy consumption and the emission of greenhouse gases that are typically associated with the production of fresh stainless steel. Therefore, it is strongly advised to recycle stainless steel sheets in order to foster sustainability and promote the principles of a circular economy.

- Q: What does "stainless steel plate" 6.0*1500c mean?

- Stainless steel plate 6.0*1500c represents stainless steel material,6 represents the stainless steel thickness,

- Q: How do you form stainless steel sheets into different shapes?

- Stainless steel sheets can be formed into different shapes through various processes such as bending, rolling, and welding. The specific method used depends on the desired shape and the thickness of the stainless steel sheet. Bending is a common method used to form stainless steel sheets into shapes such as cylinders or boxes. This process involves clamping the sheet between a punch and a die and applying force to create the desired bend. The angle and radius of the bend can be controlled by adjusting the pressure and the distance between the punch and die. Rolling is another technique employed to form stainless steel sheets into curved or cylindrical shapes. This process involves passing the sheet through a set of rollers, which gradually bend the material into the desired shape. The diameter and curvature of the final shape can be adjusted by changing the spacing and alignment of the rollers. For more complex shapes, welding is often used in conjunction with bending or rolling. In this process, multiple stainless steel sheets are joined together using heat and pressure to create the desired form. This allows for the creation of intricate shapes, such as cones or irregular geometries. In addition to these methods, specialized equipment such as hydraulic presses or hydroforming can also be utilized to form stainless steel sheets into different shapes. These techniques involve applying high pressure or fluid pressure to the sheet, resulting in deformation and the desired shape. It is important to note that forming stainless steel sheets requires skilled operators and precise machinery to ensure accuracy and quality. Additionally, the properties of the stainless steel, such as its thickness and composition, can also influence the feasibility and success of the forming process.

- Q: What's the surface of the 304 stainless steel matte board?

- NO.3 NO.2D and NO.2B coarse grinding material, 100~200# (units) of the abrasives abrasive belt grinding, building materials, kitchen appliances, NO.4 NO.2D and NO.2B intermediate grinding material, polishing surface with abrasive belt grinding 150~180# tobe obtained, this is universal, a mirror reflection of the visible with bright surface. The 'grain'NO.240 NO.2D and NO.2B fine grinding material, grinding of kitchen utensils with 240# Abrasives Abrasive BeltNO.320 NO.2D and NO.2B will be very fine grinding material, grinding of 320# abrasives abrasive belt.NO.400 gloss close to BA, NO.2B material, with 400# polishing wheel for research, general timber, building materials, kitchen utensilsHL abrasive material grinding hairline appropriate particle size of hairline grinding (150~240#) the abrasives of many buildings, building materialsNO.7 is close to mirror finish, and is polished with 600# rotary polishing wheels. It is used for decoration and decorationNO.8 mirror grinding, mirror polishing wheel, grinding, mirror, decoration

- Q: When milling the stainless steel plate, how can he deform?

- 2. clamping points should be selected so that the workpiece does not vibrate when it is machined3., tools should be selected, choose easy to cut stainless steel cutting tools

- Q: What are the different types of perforated patterns available for stainless steel sheets?

- There are several different types of perforated patterns available for stainless steel sheets, including round, square, slotted, and decorative patterns. Each pattern offers a unique aesthetic appeal and functional characteristics, making it suitable for various applications.

- Q: Are stainless steel sheets scratch resistant?

- Yes, stainless steel sheets are generally scratch resistant. Stainless steel is known for its durability and resistance to scratching, making it a popular choice for various applications. However, it is important to note that while stainless steel is resistant to most scratches, it is not completely scratch-proof. Deep or abrasive scratches can still occur, especially if the surface is exposed to harsh or abrasive materials. Regular maintenance and care, such as avoiding the use of abrasive cleaners or scrubbing pads, can help minimize the risk of scratches and maintain the appearance of stainless steel sheets.

- Q: Can stainless steel sheets be cut or welded?

- Indeed, it is possible to cut and weld stainless steel sheets. Various methods, such as shearing, plasma cutting, laser cutting, or waterjet cutting, can be utilized to cut stainless steel sheets. When it comes to welding, the process involves joining two pieces together by heating them to their melting points and, if needed, incorporating a filler material. Nevertheless, it is crucial to acknowledge that welding stainless steel necessitates specific techniques and equipment due to its distinctive attributes, including low thermal conductivity and high thermal expansion. Consequently, it is imperative to possess adequate training and expertise to guarantee a fruitful and high-quality weld.

Send your message to us

Stainless Steel sheet and Plate in Cheap price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords