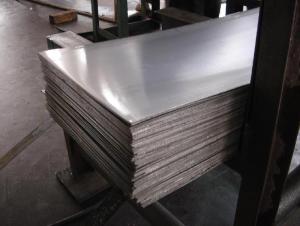

420 cold rolled stainless steel sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1、Structure of 304/2B STAINLESS STEEL SHEET.

STAINLESS STEEL SHEET IS ONE POPULAR PRODUCTS IN CHINA MARKET, IT HAVE SEVERAL DIFFERENT APPLICATIONS, SUCH AS, CONSTRUCTION, BUILDING, DECORATION, ETC.

THE GRADE ALSO INCLUDE: 200 SERIES, 300 SERIES, 400 SERIES, ETC.

Mainly applied in the industry of furniture, sports equipment, compressed containers, shipbuilding, railway and the automotive.

2、Main Features of the 304 STAINLES STEEL SHEET.

High intensity

Low welding costs.

Outstanding color compatibility after anodizing

Easy to operate. All-position welding.

Excellent corrosion resistance

Wide applicability.

Length per spool only for reference

Spool Size Weight Specifications

D300mm 6Kg~7Kg 0.8mm, 0.9mm, 1.0mm, 1.2mm, 1.6mm

5、FAQ of 304/2B STAINLESS STEEL SHEET.

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

----Now we export to South East Asia,Africa, North America,South America ect.

- Q: What is the difference between the stainless steel plate and the second board?

- The material is stainless steel plate. A soft white, and there will be rolling wheel and steel and some other bad marks;

- Q: Can stainless steel sheets be used for decorative purposes?

- Certainly, decorative purposes can be served by stainless steel sheets. Renowned for its sleek and contemporary look, stainless steel is a widely preferred option for diverse decorative uses. Its applications span across interior design, architecture, and even art installations. Stainless steel sheets can be personalized to fashion distinctive patterns, textures, and finishes, rendering them ideal for crafting captivating and visually enticing decorative elements. Moreover, stainless steel boasts exceptional durability, corrosion resistance, and simple maintenance, making it a pragmatic choice for both indoor and outdoor decorative applications.

- Q: Are stainless steel sheets suitable for food processing or medical applications?

- Yes, stainless steel sheets are highly suitable for both food processing and medical applications. Stainless steel is corrosion-resistant, durable, and easy to clean, making it ideal for environments where hygiene and cleanliness are crucial. It is also non-reactive with food or medical substances, ensuring that it does not contaminate or alter the properties of the materials it comes into contact with. Additionally, stainless steel's strength and resistance to extreme temperatures make it suitable for various processing and sterilization methods required in these industries.

- Q: How do I prevent crevice corrosion on stainless steel sheets?

- To avoid crevice corrosion on stainless steel sheets, there are a few steps you can take: 1. Opt for the correct stainless steel grade: Make sure you use a stainless steel grade that is resistant to crevice corrosion. Grades like 316 and 317L are known for their excellent resistance to this type of corrosion. 2. Optimize design: When designing structures or equipment, avoid creating crevices or areas where water or other corrosive substances can collect and stagnate. Reduce gaps, sharp edges, and overlapping surfaces to minimize the risk of crevice corrosion. 3. Regularly clean and maintain: Clean the stainless steel sheets regularly to eliminate any contaminants, deposits, or corrosive substances that may have built up. Use mild detergents and gentle cleaning agents to avoid damaging the protective oxide layer on the stainless steel surface. 4. Avoid chloride-rich environments: Chloride ions accelerate crevice corrosion on stainless steel. Stay away from exposing the sheets to environments with high chloride concentrations, such as saltwater, chlorinated solutions, and specific industrial chemicals. 5. Apply protective coatings: Consider applying protective coatings or finishes to the stainless steel sheets. These coatings act as a barrier, preventing direct contact between the stainless steel surface and corrosive substances. However, ensure that the coatings you choose are compatible with stainless steel and do not compromise its corrosion resistance. 6. Regularly inspect: Conduct regular inspections of the stainless steel sheets to check for signs of corrosion or damage. Pay special attention to areas prone to crevice corrosion and look for discoloration, pitting, or cracking. Address any issues promptly to prevent further corrosion and potential structural damage. Remember, prevention is crucial in combating crevice corrosion. By selecting the appropriate stainless steel grade, designing structures to minimize crevices, maintaining cleanliness, avoiding harsh environments, applying protective coatings, and regularly inspecting for damage, you can significantly reduce the chances of crevice corrosion on stainless steel sheets.

- Q: Can stainless steel sheets be used for outdoor furniture?

- Yes, stainless steel sheets can be used for outdoor furniture. Stainless steel is a highly durable material that is resistant to rust, corrosion, and weathering. This makes it an ideal choice for outdoor furniture as it can withstand the elements and retain its appearance and structural integrity over time. Additionally, stainless steel has a sleek and modern look that can complement various outdoor design styles. Whether it's for tables, chairs, or other outdoor furniture pieces, stainless steel sheets can provide a long-lasting and visually appealing option for outdoor use.

- Q: What are the common uses of stainless steel sheets?

- Stainless steel sheets possess distinctive properties and versatility, enabling them to be widely utilized in a myriad of applications. Some of the most prevalent uses are as follows: 1. Within the construction industry, stainless steel sheets are extensively employed for roofing, cladding, and facades. The combination of their exceptional durability, resistance to corrosion, and contemporary aesthetic appeal renders them highly desirable. 2. The automotive sector also benefits from the utilization of stainless steel sheets, particularly in the production of components such as exhaust systems, grilles, trims, and decorative elements. Their capacity to withstand heat, corrosion, and impact makes them an ideal choice for these purposes. 3. In the manufacturing of kitchen appliances like refrigerators, ovens, dishwashers, and sinks, stainless steel sheets are commonly employed. Their hygienic properties, stain resistance, and ease of maintenance contribute to their popularity in these applications. 4. The food processing industry extensively relies on stainless steel sheets due to their non-reactive nature and ease of cleaning. They are employed in the fabrication of equipment such as storage tanks, conveyor systems, work surfaces, and food preparation tables. 5. The manufacturing of medical equipment and devices heavily relies on stainless steel sheets. They are instrumental in the production of surgical instruments, dental tools, implantable devices, and hospital furniture owing to their biocompatible nature, corrosion resistance, and ease of sterilization. 6. In the aerospace industry, stainless steel sheets find application in the construction of aircraft components such as fuselage frames, engine parts, and landing gear. Their exceptional strength-to-weight ratio, resistance to extreme temperatures, and corrosion resistance render them suitable for these demanding applications. 7. Within the energy and power generation sectors, stainless steel sheets are commonly employed in power plants, oil refineries, and chemical processing plants for the construction of equipment like heat exchangers, boilers, and storage tanks. Their ability to withstand high temperatures, pressure, and corrosive environments is indispensable in these industries. 8. Stainless steel sheets also serve decorative purposes in architecture and interior design. They can be utilized to create unique and modern finishes on walls, ceilings, furniture, and decorative panels. In conclusion, stainless steel sheets are a versatile material that finds application in various industries due to their exceptional properties, including corrosion resistance, durability, hygienic properties, and aesthetic appeal.

- Q: Are stainless steel sheets resistant to pitting and crevice corrosion?

- Yes, stainless steel sheets are generally resistant to pitting and crevice corrosion. Stainless steel is known for its high corrosion resistance due to the presence of chromium, which forms a passive oxide layer on the surface of the material, protecting it from corrosion. This oxide layer acts as a barrier, preventing the penetration of corrosive substances that could cause pitting and crevice corrosion. However, it is important to note that the resistance to pitting and crevice corrosion can vary depending on the specific grade of stainless steel and the environmental conditions in which it is exposed. Some grades of stainless steel, such as 316 or 317, have enhanced resistance to these types of corrosion. In addition, certain aggressive environments, such as those with high chloride concentrations or acidic conditions, can still pose a risk to stainless steel and may require the use of more corrosion-resistant grades or additional protective measures. Overall, stainless steel sheets are highly resistant to pitting and crevice corrosion, but the specific grade and environmental factors should be considered for optimal performance.

- Q: Can stainless steel sheets be used in manufacturing processes?

- Yes, stainless steel sheets can be used in manufacturing processes. Stainless steel is a highly versatile and durable material that is commonly used in various industrial applications. Due to its corrosion resistance, strength, and heat resistance properties, stainless steel sheets are ideal for manufacturing processes that require a material to withstand harsh conditions, such as chemical processing, food and beverage production, pharmaceutical manufacturing, and automotive manufacturing. Stainless steel sheets can be formed, cut, welded, and machined to suit specific manufacturing requirements, making them a popular choice in the industry.

- Q: How do stainless steel sheets compare to other materials?

- Stainless steel sheets have several advantages over other materials, making them a popular choice in various industries. Firstly, stainless steel is known for its exceptional durability and strength. It can withstand high temperatures, pressure, and corrosion, making it suitable for a wide range of applications. This durability ensures a longer lifespan and reduces the need for frequent replacements, saving both time and money. Secondly, stainless steel sheets have excellent resistance to corrosion and rust. This property is particularly important in environments with high humidity or exposure to chemicals, as it prevents degradation and maintains the integrity of the material. Other materials, such as aluminum or carbon steel, may require protective coatings or regular maintenance to achieve similar levels of corrosion resistance. Furthermore, stainless steel sheets have a clean and smooth surface finish, making them aesthetically pleasing and easy to clean. This quality is crucial in industries such as food processing, pharmaceuticals, and healthcare, where hygiene and cleanliness are paramount. Stainless steel sheets also offer versatility in terms of fabrication and customization. They can be easily formed, welded, and shaped into different sizes and configurations, allowing for a wide range of applications. This versatility makes stainless steel sheets suitable for architectural, automotive, and industrial uses. Lastly, stainless steel is environmentally friendly. It is 100% recyclable, meaning that it can be melted down and reused without any loss in quality or performance. This recyclability reduces the demand for new materials and lessens the environmental impact associated with manufacturing processes. In summary, stainless steel sheets outperform other materials in terms of durability, corrosion resistance, cleanliness, versatility, and environmental sustainability. These qualities make stainless steel sheets a superior choice for various industries and applications.

- Q: What are the different types of colored finishes available for stainless steel sheets?

- Stainless steel sheets come in a variety of colored finishes that serve to enhance their appearance and offer different aesthetic options. Some of the most popular colored finishes include: 1. Mirror Finish: This particular finish achieves a highly reflective, mirror-like surface on the stainless steel sheets. By polishing the stainless steel surface to a high gloss, a sleek and modern look is achieved. Mirror finishes are commonly used for decorative purposes. 2. Satin Finish: Also known as a brushed or matte finish, this type of finish provides a smooth, non-reflective surface. It is achieved by brushing the stainless steel surface with an abrasive material. Satin finishes are commonly used in architectural and industrial applications, giving off a clean and contemporary appearance. 3. Colored Powder Coating: This finish involves applying a dry powder to the stainless steel surface and then curing it under heat. The result is a durable and uniform colored finish. Colored powder coatings offer a wide range of hues, allowing for customization and versatility in design. 4. PVD Coating: The process of Physical Vapor Deposition (PVD) entails depositing a thin layer of metal onto the stainless steel surface. This coating can be in various colors, such as gold, bronze, black, or rose gold. PVD coatings are highly durable and resistant to wear, making them suitable for high-traffic areas or decorative applications. 5. Colored Anodizing: This finish is achieved through an electrochemical process that creates a protective oxide layer on the stainless steel surface. By incorporating dyes into the anodizing process, a plethora of colors can be achieved. Colored anodized finishes are known for their corrosion resistance and find utility in architectural or design-oriented applications. Each of these colored finishes possesses unique characteristics and can be selected based on desired aesthetics, durability, and specific application requirements. It is crucial to consider factors such as maintenance requirements, environmental conditions, and intended use when choosing a colored finish for stainless steel sheets.

Send your message to us

420 cold rolled stainless steel sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords