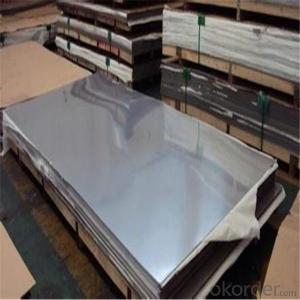

201 304 Stainless Steel Sheets cold rolled

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

304 316 cold rolled stainless steel sheet

Standard:JIS,AISI,ASTM,GB,DIN,EN

Material:201,202,316,304,304L,316,316L,321,430,etc.

Thickness:0.5mm~2.0mm

Width: 1000mm~1250mm

Length:1000mm-6000mm or as your requirement

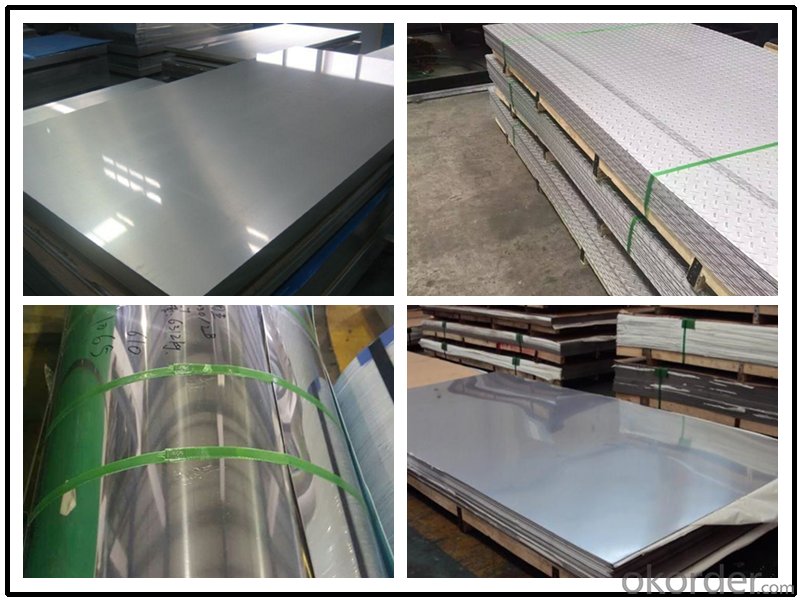

Finish:2B, BA, Hair Line, No.1,No.4, Mirror ,color,etching

Technique:cold rolled

Application:Stainless steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields.

Standard :AISI, ASTM, BS, DIN, GB, JIS

Certificate :ISO

Price:Attractive price and quality are perfect match

Packaging & Shipping

Trade terms:

Packing: Standard export seaworthy packing with waterproof paper,metal belt pack sheet,then put them in wooden pallet(or put them in wooden case),then put them in container or as customer's requirement.

MOQ: 5 metric tons

Shipping Term: FOB GUANGDONG or CNF import port

Delivery Time: 15 to 35 days after the receipt of the deposit

Payment Term: T/T 30% deposit, Balance against the copy of B/L; or L/C at sight

201 304 cold rolled stainless steel sheets

Application

- Q: How are stainless steel sheets installed?

- Different methods are used to install stainless steel sheets depending on the specific application and requirements. Here are several common installation methods for stainless steel sheets: 1. Adhesive: A popular and straightforward method involves using a specialized adhesive to bond the stainless steel sheet to the desired surface. The adhesive is applied to the back of the sheet, which is then firmly pressed onto the surface. This method is suitable for flat or slightly curved surfaces and results in a seamless and clean installation. 2. Mechanical fasteners: When additional strength and stability are necessary, stainless steel sheets can be installed using mechanical fasteners like screws, bolts, or rivets. These fasteners are drilled or screwed through the sheet and into the surface to secure it. This method is often used for installations that require resistance to external forces or for attaching stainless steel sheets to structural components. 3. Welding: In some cases, particularly for large or complex installations, welding may be employed to connect stainless steel sheets together or to other metal structures. Welding creates a strong and permanent bond between the sheets, ensuring a secure installation. However, this method requires skilled professionals and specialized equipment to ensure proper welding techniques and prevent damage to the stainless steel. 4. Magnetic attachment: Certain stainless steel sheets are designed with a magnetic backing, allowing them to be easily attached to magnetic surfaces. This method offers quick and convenient installation as the sheets can be easily repositioned or removed if necessary. However, it is important to ensure that the magnetic surface is clean and free from debris that could affect the adhesion. Before installing stainless steel sheets, it is crucial to thoroughly clean the surface and remove any dirt, dust, or grease. This preparation will help ensure a secure and long-lasting installation. Additionally, following the manufacturer's instructions and guidelines specific to the stainless steel sheet being installed is essential for achieving the best results.

- Q: How do you prevent pitting on stainless steel sheets?

- To prevent pitting on stainless steel sheets, there are several steps you can take: 1. Ensure proper cleaning and maintenance: It is important to regularly clean the stainless steel sheets using mild soap or a non-abrasive cleaning solution. Avoid using harsh chemicals, bleach, or abrasive cleaners as they can harm the protective layer on the surface. After cleaning, make sure to thoroughly rinse and dry the sheets to eliminate any residue that could lead to pitting. 2. Avoid contact with corrosive substances: Although stainless steel is highly resistant to corrosion, prolonged exposure to certain chemicals or substances can still cause pitting. It is advisable to avoid contact with chloride-based cleaners, strong acids, or solutions containing high concentrations of salt. If accidental contact occurs, immediately rinse the sheets with clean water and dry them thoroughly. 3. Protect against physical damage: Pitting can occur on stainless steel sheets if they get scratched or damaged. It is crucial to handle and install the sheets with care to prevent any sharp or abrasive objects from scratching the surface. During transportation and storage, consider using protective films or covers to minimize the risk of physical damage. 4. Apply a protective coating: To enhance the natural corrosion resistance of stainless steel and reduce the risk of pitting, you may want to consider applying a protective coating or passivating treatment to the sheets. It is recommended to consult with a professional or supplier to determine the most suitable coating or treatment for your specific stainless steel grade and application. 5. Conduct regular inspection and maintenance: It is important to periodically inspect the stainless steel sheets for any signs of pitting or corrosion. Promptly address any issues by cleaning, repairing, or replacing the affected areas. Regular maintenance and inspection will help identify potential problems early on and prevent them from worsening. By following these preventive measures, you can minimize the occurrence of pitting on stainless steel sheets, extend their lifespan, and maintain their aesthetic appeal.

- Q: Are stainless steel sheets suitable for medical equipment?

- Indeed, medical equipment can be fabricated using stainless steel sheets. The utilization of stainless steel in medical equipment is widely favored due to its remarkable resistance to corrosion and its ability to endure. It boasts effortless cleaning and sterilization, rendering it fitting for employment in healthcare facilities where cleanliness and hygiene are paramount. Furthermore, the high strength-to-weight ratio of stainless steel permits the creation of lightweight yet robust medical equipment. Moreover, its magnetic permeability is low, rendering it an ideal option for situations necessitating minimal electromagnetic interference. All in all, stainless steel sheets are a dependable and pragmatic selection for the production of medical equipment.

- Q: Can stainless steel sheets be used for railway station facades?

- Yes, stainless steel sheets can be used for railway station facades. Stainless steel is a durable and corrosion-resistant material that can withstand various weather conditions. Its aesthetic appeal and low maintenance requirements make it a suitable choice for enhancing the appearance and functionality of railway station facades.

- Q: Can stainless steel sheets be used for athletic equipment?

- Indeed, athletic equipment can make use of stainless steel sheets. Renowned for their durability, resistance to corrosion, and strength, stainless steel proves to be the perfect material for myriad athletic equipment purposes. Gym equipment, like weightlifting bars, dumbbells, and exercise benches, regularly employs stainless steel in its construction. Moreover, basketball hoops, soccer goalposts, and other outdoor sports equipment rely on stainless steel sheets for their ability to endure harsh weather conditions. Furthermore, stainless steel sheets offer versatility by allowing customization and fabrication into a range of shapes and sizes, catering to diverse athletic equipment requirements.

- Q: Are stainless steel sheets safe for medical applications?

- Yes, stainless steel sheets are safe for medical applications. They are widely used in the medical industry due to their excellent corrosion resistance, biocompatibility, and durability. Stainless steel is easy to clean, sterilize, and maintain, making it suitable for surgical instruments, medical devices, and equipment used in healthcare settings.

- Q: What kind of screws do you choose for stainless steel plates?

- If it's a fixed plate, ordinary ones will doOf course, stainless steel screws are the best

- Q: What is the Young's modulus of stainless steel sheets?

- The Young's modulus of stainless steel sheets can vary depending on the specific grade and composition of the stainless steel. Generally, stainless steel has a high Young's modulus, typically ranging from 190 to 220 gigapascals (GPa). This means that stainless steel sheets have a high stiffness and resistance to deformation under applied stress. However, it is important to note that the exact Young's modulus may vary slightly depending on factors such as temperature, manufacturing process, and the specific alloy used in the stainless steel sheets.

- Q: Is the cold rolled steel plate good or the stainless steel plate?

- Although it is impossible to provide specific parameters to prove, in fact, most stainless steel plates are used in oven making. Corrosion resistant, easy to clean, safe and sanitary.

- Q: Can stainless steel sheets be used for decorative lighting fixtures?

- Yes, stainless steel sheets can certainly be used for decorative lighting fixtures. Stainless steel is a versatile and durable material that can be shaped and formed into various designs and patterns, making it ideal for creating unique and eye-catching lighting fixtures. Its sleek and modern appearance adds a touch of elegance to any space, making it a popular choice for decorative purposes. Additionally, stainless steel is resistant to corrosion and heat, ensuring that the lighting fixtures will remain in excellent condition for a long time.

Send your message to us

201 304 Stainless Steel Sheets cold rolled

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords