Cold Rolled Sheet And Hot Rolled Sheet Cheapest Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Product Description

Cold rolled aluminum sheet and cold rawn sheet and hot drawn plate are widely used in the field of construction field and decoration field, etc.

There are many different grades, such as: 1000 series, 2000 series, 3000 series, 5052,5754,5083,6061,6063,8011, etc.

The temper is include H14, H22, H14, H12,H22,H24,H44,H112,H114,etc.

2. Main features of the product

a.Competitive price

b.Frist-Class Service.

c. Shortest service.

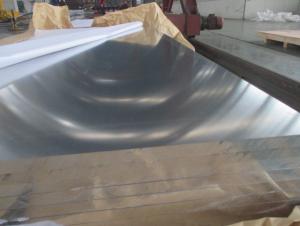

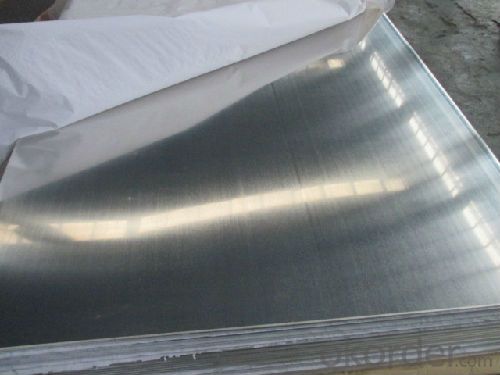

3. Image.

4. Product detailed sizes:

1000mm*2000mm, 1219mm*2438mm,1220mm*2440mm,1000*1000, 500mm*500mm,600mm*600mm,.

1500mm*3000mm, etc.

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or others.

What is the width range?

---It is from 1000mm to 2500mm, etc.

---Normally it is around 9000 tons totally.

Where is your client from?

---Normally it is from Japan, USA, ENGLISH, Singapore, etc.

What is your mainly products?

---Normally they are aluminum sheet, checkered sheet, hot rolled sheet and cold rolled sheet,

mirror finish aluminium sheet, aluminum casting coil, etc.

- Q: How do you prevent pitting on stainless steel sheets?

- To prevent pitting on stainless steel sheets, there are several steps you can take: 1. Ensure proper cleaning and maintenance: It is important to regularly clean the stainless steel sheets using mild soap or a non-abrasive cleaning solution. Avoid using harsh chemicals, bleach, or abrasive cleaners as they can harm the protective layer on the surface. After cleaning, make sure to thoroughly rinse and dry the sheets to eliminate any residue that could lead to pitting. 2. Avoid contact with corrosive substances: Although stainless steel is highly resistant to corrosion, prolonged exposure to certain chemicals or substances can still cause pitting. It is advisable to avoid contact with chloride-based cleaners, strong acids, or solutions containing high concentrations of salt. If accidental contact occurs, immediately rinse the sheets with clean water and dry them thoroughly. 3. Protect against physical damage: Pitting can occur on stainless steel sheets if they get scratched or damaged. It is crucial to handle and install the sheets with care to prevent any sharp or abrasive objects from scratching the surface. During transportation and storage, consider using protective films or covers to minimize the risk of physical damage. 4. Apply a protective coating: To enhance the natural corrosion resistance of stainless steel and reduce the risk of pitting, you may want to consider applying a protective coating or passivating treatment to the sheets. It is recommended to consult with a professional or supplier to determine the most suitable coating or treatment for your specific stainless steel grade and application. 5. Conduct regular inspection and maintenance: It is important to periodically inspect the stainless steel sheets for any signs of pitting or corrosion. Promptly address any issues by cleaning, repairing, or replacing the affected areas. Regular maintenance and inspection will help identify potential problems early on and prevent them from worsening. By following these preventive measures, you can minimize the occurrence of pitting on stainless steel sheets, extend their lifespan, and maintain their aesthetic appeal.

- Q: Can stainless steel sheets be used for outdoor furniture or fixtures?

- Yes, stainless steel sheets can be used for outdoor furniture or fixtures. Stainless steel is highly resistant to corrosion, making it a suitable material for outdoor applications. It is durable, weather-resistant, and can withstand harsh environmental conditions. Additionally, stainless steel has an attractive appearance and can be easily cleaned and maintained, making it an ideal choice for outdoor furniture or fixtures.

- Q: Can stainless steel sheets be used for filtration applications?

- Yes, stainless steel sheets can be used for filtration applications. Stainless steel is known for its corrosion resistance, durability, and high strength, making it suitable for various filtration processes. It can effectively filter out particles, contaminants, and impurities in liquids and gases, making it a popular choice for industries such as food and beverage, pharmaceutical, chemical, and wastewater treatment.

- Q: What are the different types of stainless steel sheet finishes for food processing applications?

- There are several types of stainless steel sheet finishes commonly used in food processing applications. These include mill finishes, which are smooth and unpolished; 2B finishes, which are slightly reflective and have a smooth, matte appearance; and mirror finishes, which have a highly reflective surface. Additionally, there are also brushed finishes, which have a textured appearance, and embossed finishes, which feature raised patterns or designs on the surface.

- Q: How do you form stainless steel sheets into different shapes?

- Stainless steel sheets can be formed into different shapes through various processes such as bending, rolling, and welding. The specific method used depends on the desired shape and the thickness of the stainless steel sheet. Bending is a common method used to form stainless steel sheets into shapes such as cylinders or boxes. This process involves clamping the sheet between a punch and a die and applying force to create the desired bend. The angle and radius of the bend can be controlled by adjusting the pressure and the distance between the punch and die. Rolling is another technique employed to form stainless steel sheets into curved or cylindrical shapes. This process involves passing the sheet through a set of rollers, which gradually bend the material into the desired shape. The diameter and curvature of the final shape can be adjusted by changing the spacing and alignment of the rollers. For more complex shapes, welding is often used in conjunction with bending or rolling. In this process, multiple stainless steel sheets are joined together using heat and pressure to create the desired form. This allows for the creation of intricate shapes, such as cones or irregular geometries. In addition to these methods, specialized equipment such as hydraulic presses or hydroforming can also be utilized to form stainless steel sheets into different shapes. These techniques involve applying high pressure or fluid pressure to the sheet, resulting in deformation and the desired shape. It is important to note that forming stainless steel sheets requires skilled operators and precise machinery to ensure accuracy and quality. Additionally, the properties of the stainless steel, such as its thickness and composition, can also influence the feasibility and success of the forming process.

- Q: Can stainless steel sheets be used for architectural wire mesh?

- Yes, stainless steel sheets can be used for architectural wire mesh. Stainless steel is a durable and corrosion-resistant material, making it suitable for various architectural applications, including wire mesh installations. It offers strength, versatility, and an attractive appearance, making it an ideal choice for creating functional and aesthetically pleasing architectural wire mesh designs.

- Q: Are stainless steel sheets suitable for marine environments?

- Yes, stainless steel sheets are suitable for marine environments. Stainless steel is highly resistant to corrosion and rust due to the presence of chromium in its composition. This makes it an ideal material for use in marine environments where constant exposure to saltwater and moisture can cause other metals to corrode quickly. Stainless steel sheets also have good mechanical properties, high strength, and excellent durability, which further make them suitable for marine applications. Additionally, stainless steel is easy to clean and maintain, ensuring its longevity and performance in harsh marine conditions.

- Q: How do you determine the hardness of stainless steel sheets?

- The hardness of stainless steel sheets can be determined using various methods such as the Rockwell hardness test, Brinell hardness test, or Vickers hardness test. These tests involve applying a specific amount of force or pressure to the surface of the steel sheet and measuring the depth of indentation created. The hardness value obtained from these tests indicates the resistance of the stainless steel sheet to deformation or scratching, thus providing a measure of its hardness.

- Q: How do stainless steel sheets compare to other materials, such as aluminum or carbon steel?

- Stainless steel sheets possess several advantages when compared to materials like aluminum or carbon steel. Their corrosion resistance stands as one of the main benefits. By containing chromium, stainless steel forms a passive film on its surface, guarding it against rust and other forms of corrosion. As a result, stainless steel sheets prove ideal for outdoor and marine applications, where exposure to moisture and corrosive elements is common. In terms of strength, stainless steel sheets generally surpass aluminum but fall short of carbon steel. Nevertheless, through heat treatment, stainless steel sheets can be hardened, increasing their strength and durability. This characteristic renders them suitable for applications that demand high strength and resistance to wear and tear. Stainless steel sheets also exhibit remarkable heat resistance. They can withstand high temperatures without compromising their structural integrity, making them appropriate for use in industries such as food processing, chemicals, and petrochemicals. Another advantage of stainless steel sheets lies in their aesthetic appeal. With their sleek and modern appearance, they complement various design styles. Architects and interior designers frequently include stainless steel sheets in their projects, particularly when visual appeal holds significance. However, despite the numerous advantages, it is important to consider certain factors when working with stainless steel sheets. Stainless steel can be more expensive than aluminum or carbon steel, particularly for high-grade alloys. Additionally, its higher strength and hardness may pose challenges during shaping and machining. Specialized tools and techniques may be necessary when working with stainless steel sheets. In conclusion, stainless steel sheets offer a unique combination of corrosion resistance, strength, heat resistance, and aesthetic appeal. Depending on the specific requirements of a project, stainless steel may be the preferred choice over materials like aluminum or carbon steel.

- Q: Can stainless steel sheets be used for heat shields?

- Yes, stainless steel sheets can be used for heat shields. Stainless steel is known for its high heat resistance and durability, making it an excellent choice for protecting against heat transfer. Stainless steel sheets can effectively shield against radiant heat, convective heat, and conductive heat, making them suitable for a variety of applications such as automotive heat shields, industrial equipment, and home appliances. Additionally, stainless steel sheets offer corrosion resistance and are easy to clean, making them a practical and long-lasting choice for heat shield applications.

Send your message to us

Cold Rolled Sheet And Hot Rolled Sheet Cheapest Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords