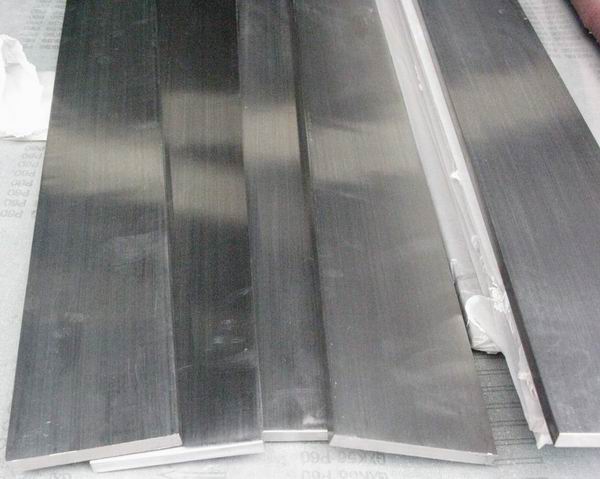

Stainless Steel Flat

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

304 Stainless Steel Flat Details:

| Minimum Order Quantity: | 5 Tons | Unit: | m.t. | Loading Port: | China Main Port |

| Supply Ability: | 1000 Tons Per Month | Payment Terms: | TT or LC |

Product Description:

Stainless Steel Flats

1. Standard: AISI, GB, JIS, ASTM, DIN, EN

2. Grade: 1).200Series: 201,202.

2).300Series: 301,302,303,304,304L,316,316L,321.

3).400Series: 410,410S,416,420,430,430F.

3. Size:3x25mm- 80x250mm

4. Length: 2m-6m

5. Craft: HRAP, or cold drawn

6. Stainless Steel Flat Bar Surface: Pickling or polished

7. MOQ: 1 Ton

8. Delivery: within 20 days

9. Package: Waterproof with tape

10. Application: These products are widely supplied to areas of machine-made industry, chemical industry, shipping industry,architecture, food industry, household products etc.

Size | Thickness (mm) | |||||||||||

Width (mm) | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 14 | 16 | 20 | 25 | 30 |

Theoretical Weight (kg/m) | ||||||||||||

10 | 0.238 | 0.32 | 0.4 | 0.48 | 0.63 | |||||||

15 | 0.36 | 0.48 | 0.59 | 0.71 | 0.95 | 1.19 | ||||||

20 | 0.476 | 0.63 | 0.79 | 0.95 | 1.27 | 1.59 | 1.9 | |||||

25 | 0.585 | 0.79 | 0.99 | 1.19 | 1.59 | 1.98 | 2.38 | |||||

30 | 0.714 | 0.95 | 1.19 | 1.43 | 1.9 | 2.38 | 2.85 | 3.33 | 3.81 | 4.75 | 5.948 | |

40 | 0.952 | 1.27 | 1.59 | 1.9 | 2.54 | 3.17 | 3.81 | 4.44 | 5.08 | 6.34 | 7.93 | 9.52 |

50 | 1.19 | 1.59 | 1.98 | 2.38 | 3.17 | 3.97 | 4.76 | 5.55 | 6.34 | 7.93 | 9.91 | 11.9 |

60 | 1.428 | 1.9 | 2.38 | 2.85 | 3.81 | 4.76 | 5.71 | 6.66 | 7.61 | 9.52 | 11.9 | 14.27 |

70 | 2.22 | 2.78 | 3.33 | 4.44 | 5.55 | 6.66 | 7.77 | 8.88 | 11.1 | 13.88 | 16.65 | |

80 | 3.17 | 3.81 | 5.08 | 6.34 | 7.61 | 8.88 | 10.15 | 12.69 | 15.86 | 19.03 | ||

90 | 3.57 | 4.28 | 5.71 | 7.14 | 8.56 | 9.99 | 11.42 | 14.27 | 17.84 | 21.41 | ||

100 | 3.97 | 4.76 | 6.34 | 7.93 | 9.52 | 11.1 | 12.69 | 15.86 | 19.82 | 23.79 | ||

110 | 5.23 | 6.98 | 8.72 | 10.47 | 12.21 | 13.96 | 17.45 | 21.81 | 26.17 | |||

120 | 5.71 | 7.61 | 9.52 | 11.42 | 13.32 | 15.23 | 19.03 | 23.79 | 28.55 | |||

130 | 6.19 | 8.25 | 10.31 | 12.37 | 14.43 | 16.49 | 20.62 | 25.77 | 30.93 | |||

140 | 6.66 | 8.88 | 11.1 | 13.32 | 15.54 | 17.76 | 22.2 | 27.76 | 33.31 | |||

150 | 7.14 | 9.52 | 11.9 | 14.27 | 16.65 | 19.03 | 23.79 | 29.74 | 35.69 | |||

160 | 7.61 | 12.69 | 15.23 | 17.76 | 20.3 | 25.38 | 31.72 | 38.06 | ||||

170 | 13.48 | 16.18 | 18.87 | 21.57 | 26.96 | 33.7 | 40.44 | |||||

180 | 14.27 | 17.13 | 19.98 | 22.84 | 28.55 | 35.69 | 42.82 | |||||

- Q: Can stainless steel sheets be used for fireplaces?

- Yes, stainless steel sheets can be used for fireplaces. Stainless steel is a popular material for fireplace construction due to its high resistance to heat and corrosion. It is durable and can withstand the extreme temperatures generated by a fireplace, making it a suitable choice for both indoor and outdoor fireplaces. Additionally, stainless steel sheets can be customized and fabricated to fit any fireplace design, offering versatility in aesthetics and functionality.

- Q: Can stainless steel sheets be used for storage containers?

- Yes, stainless steel sheets can be used for storage containers. Stainless steel is a durable and corrosion-resistant material, making it suitable for storing various items safely and maintaining their integrity.

- Q: Are stainless steel sheets resistant to chemicals and acids?

- Stainless steel sheets possess resistance against chemicals and acids, thanks to the high percentage of chromium they contain. This results in the formation of a protective layer on the metal's surface, granting it exceptional resistance to corrosion and damage caused by chemicals and acids. Moreover, the inclusion of elements like nickel and molybdenum further enhances this corrosion-resistant quality. Industries like chemical processing, pharmaceuticals, food and beverage, and automotive widely employ stainless steel sheets due to their exposure to aggressive chemicals and acids. The reliability and durability of stainless steel in withstanding corrosion and chemical attack render it an ideal material for applications requiring such resistance.

- Q: Are stainless steel sheets resistant to high temperatures?

- Yes, stainless steel sheets are generally resistant to high temperatures. Stainless steel is known for its excellent heat resistance properties, making it suitable for a wide range of high-temperature applications. The composition of stainless steel, which includes chromium, nickel, and other alloying elements, creates a protective oxide layer on its surface. This oxide layer acts as a barrier against oxidation and prevents the steel from corroding or weakening at elevated temperatures. Stainless steel sheets can withstand temperatures up to around 1500°F (815°C) without losing their structural integrity. However, the exact temperature resistance may vary depending on the specific grade and thickness of the stainless steel sheet. It is always recommended to consult the manufacturer's specifications or seek professional advice for specific high-temperature applications.

- Q: Are stainless steel sheets suitable for water treatment applications?

- Yes, stainless steel sheets are highly suitable for water treatment applications. Stainless steel is known for its excellent corrosion resistance, making it the ideal choice for environments where water and moisture are present. It is resistant to rust, staining, and pitting, which ensures the longevity and durability of the sheets in water treatment facilities. Stainless steel sheets also offer hygienic properties, as they are easy to clean and maintain. This is crucial in water treatment applications where cleanliness and sanitation are of utmost importance. Additionally, stainless steel is non-reactive with water, meaning it does not leach harmful substances into the water being treated. Furthermore, stainless steel sheets are strong and can withstand high pressures and temperatures. This is critical in water treatment processes that involve filtration, disinfection, and other treatment methods that may require intense conditions. Overall, stainless steel sheets are an excellent choice for water treatment applications due to their corrosion resistance, hygienic properties, strength, and durability. They provide a reliable and long-lasting solution for various components in water treatment facilities, including tanks, pipes, valves, and other equipment.

- Q: How do you prevent pitting or crevice corrosion on stainless steel sheets?

- To prevent pitting or crevice corrosion on stainless steel sheets, there are several measures that can be taken: 1. Proper alloy selection: Choosing the right grade of stainless steel is crucial. Grades with higher levels of chromium, molybdenum, and nickel provide better resistance to corrosion. 2. Surface finishing: Ensuring a smooth and clean surface is essential to prevent corrosion. Rough surfaces or scratches can act as initiation sites for corrosion. Polishing or electropolishing the stainless steel sheets can help create a smoother surface. 3. Regular cleaning and maintenance: Regular cleaning using mild detergents and non-abrasive cleaners is important to remove contaminants that may corrode the stainless steel sheets. It is also necessary to avoid using chlorine-based cleaners or abrasive materials that can damage the protective oxide layer. 4. Avoiding stagnant conditions: Pitting and crevice corrosion are often intensified in stagnant environments. Ensuring proper drainage and avoiding the accumulation of stagnant water or debris can help prevent this type of corrosion. 5. Control of environmental factors: Stainless steel sheets should be protected from exposure to aggressive chemicals, such as chloride-containing solutions or acidic substances. Proper ventilation and humidity control can also help reduce the risk of corrosion. 6. Use of protective coatings: Applying protective coatings, such as paints or passivation treatments, can provide an additional layer of protection against pitting and crevice corrosion. 7. Regular inspections: Conducting regular inspections to detect any signs of corrosion early on can help prevent further damage. Prompt remedial actions, such as repairing damaged coatings or addressing any drainage issues, can prevent the spread of corrosion. By following these preventive measures, the risk of pitting or crevice corrosion on stainless steel sheets can be significantly reduced, ensuring their longevity and maintaining their aesthetic appeal.

- Q: Are stainless steel sheets suitable for food display cases?

- Yes, stainless steel sheets are suitable for food display cases. Stainless steel is widely used in the food industry due to its hygienic properties and durability. It is resistant to corrosion, staining, and bacterial growth, which makes it an ideal material for food display cases. Stainless steel is also easy to clean and maintain, ensuring a safe and clean food display environment. Additionally, stainless steel has a sleek and modern appearance that enhances the presentation of food items, making it a popular choice for food display cases in various establishments such as bakeries, delis, and supermarkets.

- Q: What are the benefits of using patterned stainless steel sheets in interior design?

- Using patterned stainless steel sheets in interior design offers numerous benefits. Firstly, these sheets provide a unique and modern aesthetic to any space. The patterns etched into the stainless steel can range from geometric designs to intricate motifs, adding a touch of elegance and visual interest to walls, ceilings, or furniture. This can enhance the overall ambiance of a room and make it stand out. Secondly, patterned stainless steel sheets are highly durable and long-lasting. Stainless steel is known for its strength and resistance to corrosion, making it an ideal material for interior design applications. These sheets can withstand daily wear and tear, making them suitable for high-traffic areas such as restaurants, hotels, or public spaces. Moreover, patterned stainless steel sheets are low maintenance. Unlike other materials, stainless steel is easy to clean and does not require special care or regular maintenance. Simple wiping with a damp cloth or using mild cleaning agents is sufficient to keep the sheets looking pristine. This makes them a practical choice for interior design, especially in areas where hygiene is crucial. Additionally, patterned stainless steel sheets offer versatility in design. They can be used in various applications, including wall cladding, room dividers, backsplashes, or even as decorative accents. With a wide range of patterns and finishes available, designers have the freedom to create unique and customized looks to suit any style or theme. Lastly, using patterned stainless steel sheets in interior design is environmentally friendly. Stainless steel is a recyclable material, meaning it can be reused or repurposed without causing harm to the environment. By incorporating sustainable materials into interior design, we contribute to reducing waste and promoting eco-conscious practices. Overall, the benefits of using patterned stainless steel sheets in interior design include their aesthetic appeal, durability, low maintenance requirements, versatility, and environmental friendliness. These sheets offer a practical and visually pleasing solution to elevate the design of any space.

- Q: What is the lifespan of stainless steel sheets?

- The lifespan of stainless steel sheets can vary depending on various factors such as the grade of stainless steel, the environment in which they are used, and the maintenance practices followed. In general, stainless steel sheets have a long lifespan and are known for their durability and corrosion resistance. They are designed to withstand harsh conditions and are resistant to rust, stains, and other forms of degradation. Stainless steel sheets are typically made from austenitic stainless steel, which is known for its high levels of chromium and nickel. These elements provide excellent corrosion resistance and make stainless steel sheets highly resistant to rust and staining. As a result, stainless steel sheets can last for many years, often outlasting other materials such as aluminum or regular steel. The lifespan of stainless steel sheets can be further extended through proper care and maintenance. Regular cleaning and removal of any contaminants or debris can help prevent corrosion and maintain the appearance and performance of the sheets. Additionally, applying protective coatings or finishes can provide an extra layer of protection against corrosion and wear. While it is difficult to provide an exact lifespan for stainless steel sheets due to the variability of factors involved, with proper care and maintenance, they can easily last for several decades. In some cases, stainless steel sheets have been known to last for over a century. Therefore, investing in stainless steel sheets is often seen as a long-term solution, offering durability and cost-effectiveness over an extended period.

- Q: Can stainless steel sheets be used for food processing?

- Yes, stainless steel sheets are commonly used in food processing due to their excellent corrosion resistance, durability, and ease of cleaning. They do not react with food, making them safe for use in various food processing applications such as food preparation surfaces, equipment, and storage containers.

Send your message to us

Stainless Steel Flat

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords