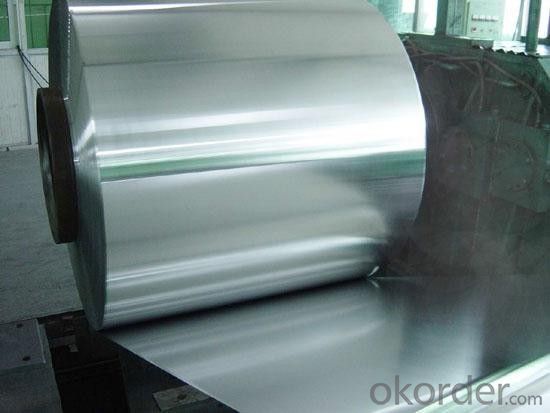

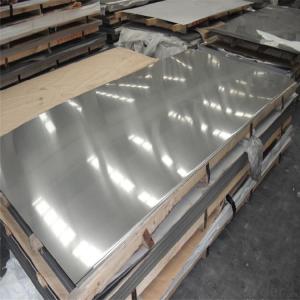

Stainless Steel sheet 304 with 4MM Thickness in high quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot sale stainless steel sheet 201/202/304/304l/316/316l/430 in china alibaba

Description of Stainless Steel Sheet:

Description | steel sheet,hot rolled steel sheet,cold rolled steel sheet, steel sheet,sheet,steel plate |

Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

Application | Steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. |

Packaging | Standard export sea-worthy packing |

Delivery time | 10-30 days |

Quality | No.1 |

Productivity | 500 tons/Day |

Note | Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured. |

Contacts | If you have any question,please feel free contact me. |

Stainless steel sheet surface finish characteristics

Surface finish | Characteristics and application |

2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

No.1 | Polished with abrasive belt of grit#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

No.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria, but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc. |

8K | The product have excellent brightness and prefer reflexivity can to be the mirror. |

Main Features of stainless steel sheet :

•Escalator, Elevator, Doors

•Furniture

•Production tools, Kitchen appliances, freezers, cold rooms

•Auto Parts

•Machinery and Packaging

•Equipment and Medical devices

•Transport system

Product Details:

Sandard Seaworth Packing(wooden packing with water proof paper)

FAQ:

1. What's the quality?

very fine

2. How long get reply?

within 24 hours

If you have any question about stainless steel sheets,donot forget to sending the email to Us! You will get the competitive Price and have a very good experience about the Buying Process! CNBM International Corporation is always your trustful friend!

- Q: What are the different types of stainless steel sheets?

- There is a variety of stainless steel sheets to choose from, each with its own unique properties and uses. Here are some of the most commonly used types: 1. Austenitic stainless steel sheets are widely used due to their excellent corrosion resistance and high ductility. They are non-magnetic and can be easily formed, making them suitable for various applications like kitchen equipment, architectural structures, and automotive components. 2. Ferritic stainless steel sheets have a lower chromium content compared to austenitic stainless steel. They offer good corrosion resistance in specific environments and are often used in applications that require high temperature resistance, such as industrial ovens and exhaust systems. 3. Martensitic stainless steel sheets are known for their high strength and hardness. They are magnetic and provide good corrosion resistance, making them suitable for applications that require both strength and corrosion resistance, like knives, turbine blades, and valve parts. 4. Duplex stainless steel sheets combine the properties of both austenitic and ferritic stainless steels. They have excellent corrosion resistance, high strength, and good weldability. Duplex stainless steel is commonly used in industries such as chemical processing, oil and gas, and marine environments. 5. Precipitation-hardening stainless steel sheets are heat treatable, offering high strength and excellent corrosion resistance. They are commonly used in applications that require a high strength-to-weight ratio, such as aerospace components, springs, and shafts. These examples highlight the variety of stainless steel sheets available. The choice of which type to use depends on specific application requirements, considering factors such as corrosion resistance, strength, formability, and cost.

- Q: Are stainless steel sheets suitable for laboratory equipment?

- Yes, stainless steel sheets are highly suitable for laboratory equipment. Stainless steel is known for its excellent corrosion resistance, making it ideal for use in laboratory settings where chemicals and other corrosive substances are frequently used. It is also easy to clean and maintain, which is crucial for maintaining a sterile environment in a laboratory. Furthermore, stainless steel is durable and can withstand high temperatures, making it suitable for a wide range of laboratory applications. Its strength and resistance to impact and wear ensure that laboratory equipment made from stainless steel can withstand rigorous use and last for a long time. Overall, stainless steel sheets offer a reliable and versatile material option for laboratory equipment.

- Q: How do you remove oil stains from stainless steel sheets?

- In order to eliminate oil stains from stainless steel sheets, the following steps can be followed: 1. To start, utilize a clean cloth or paper towel to wipe the affected area and remove any excess oil or grease. 2. Combine a mild dish soap with warm water in a bowl or bucket. Dip a soft sponge or cloth into the soapy mixture and gently scrub the stained area using circular motions. 3. For more stubborn stains, a non-abrasive cleaner specifically designed for stainless steel can be employed. Apply a small amount of the cleaner to the stained area and utilize a soft cloth to rub it in. It is important to adhere to the manufacturer's instructions for the cleaner. 4. Thoroughly rinse the area with warm water to eliminate any soap residue. 5. To further restore shine and eliminate any remaining stains, a paste can be created by combining baking soda and water. Apply the paste to the stained area and allow it to sit for a few minutes. Then, gently scrub with a soft cloth or sponge. Rinse with warm water and dry with a clean towel. 6. To prevent future stains, it is advisable to consider using a stainless steel cleaner or polish. These products can aid in maintaining shine and making it easier to clean any spills or stains that may occur. It is essential to always test any cleaning product or method on a small, inconspicuous area of the stainless steel sheet before applying it to the entire surface. Additionally, it is important to avoid using abrasive materials or scrub brushes with harsh bristles as they can cause scratches on the stainless steel.

- Q: What are the color options for stainless steel sheets?

- The color options for stainless steel sheets are typically limited to the natural silver-gray hue of stainless steel itself. However, certain surface treatments and coatings can be applied to stainless steel sheets to create different colors such as black, gold, bronze, and even vibrant shades like blue and red.

- Q: What are the different types of stainless steel sheet patterns available?

- There are several different types of stainless steel sheet patterns available, including plain, diamond, quilted, and hammered. Plain patterns have a smooth, flat surface, while diamond patterns feature raised diamond-shaped ridges. Quilted patterns have a decorative quilt-like design, and hammered patterns have a textured, hammered appearance. These various patterns offer different aesthetic options for stainless steel sheets.

- Q: Can stainless steel sheets be used for railway station facades?

- Yes, stainless steel sheets can be used for railway station facades. Stainless steel is a durable and corrosion-resistant material that can withstand various weather conditions. Its aesthetic appeal and low maintenance requirements make it a suitable choice for enhancing the appearance and functionality of railway station facades.

- Q: How can I classify stainless steel plates?

- Classification according to the use of stainless steel, can be divided into: the bridge plate, boiler plate, shipbuilding plate, armor plate, automotive steel, steel roof, structural steel, electrical steel (steel sheet), special spring steel, solar panels (hoilik steel).

- Q: Can stainless steel sheets be used in marine environments?

- Yes, stainless steel sheets can be used in marine environments. Stainless steel is highly resistant to corrosion, making it suitable for marine applications where it will be exposed to saltwater and high humidity. It is commonly used in marine vessels, offshore platforms, and other structures that require durability and resistance to rust and corrosion.

- Q: Are stainless steel sheets safe for medical applications?

- Yes, stainless steel sheets are safe for medical applications. They are widely used in the medical industry due to their excellent corrosion resistance, biocompatibility, and durability. Stainless steel is easy to clean, sterilize, and maintain, making it suitable for surgical instruments, medical devices, and equipment used in healthcare settings.

- Q: Can stainless steel sheets be used in high-pressure environments?

- High-pressure environments can certainly accommodate the use of stainless steel sheets. Renowned for remarkable strength and corrosion resistance, stainless steel proves itself fitting for tasks demanding high-pressure endurance. It remains intact and unyielding under immense pressure, never succumbing to deformation or fracture. Consequently, it emerges as an ideal choice for industries like oil and gas, chemical processing, and power generation, which frequently operate in high-pressure settings. Furthermore, stainless steel sheets retain their structural integrity and performance at elevated temperatures, bolstering their already impressive suitability for high-pressure situations.

Send your message to us

Stainless Steel sheet 304 with 4MM Thickness in high quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords