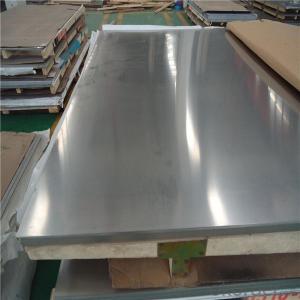

1 4 Stainless Steel Plate

1 4 Stainless Steel Plate Related Searches

1/4 In Stainless Steel Plate 3 4 Stainless Steel Pipe 1 4 Stainless Steel Plate 3 4 Stainless Steel Tubing 1/4 Stainless Steel Rod 1/4 Stainless Steel Tubing 17 4 Stainless Steel Properties 17 4 Ph Stainless Steel Stainless Steel 17-4 17-4 Stainless SteelHot Searches

Tensar Structural Geogrid 1 4 Aluminum Plate Home Depot 1 4 Aluminum Plate Near Me 1 4 Aluminum Plate Home Depot 1 4 Aluminum Plate Near Me1 4 Stainless Steel Plate Supplier & Manufacturer from China

Okorder.com is a professional 1 4 Stainless Steel Plate supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest 1 4 Stainless Steel Plate firm in China.Hot Products

FAQ

- Steel strips are commonly used in a variety of applications such as automotive industry, construction, manufacturing, and packaging. They are used for making various components and parts, like springs, brackets, clips, and connectors. Additionally, steel strips are utilized in metalworking processes such as stamping, forming, and blanking to create precision parts. They are also used for reinforcement purposes in concrete structures and for packaging materials in the form of metal strapping.

- Steel strips can be processed for UV resistance through various methods such as applying a UV-resistant coating or using a galvanizing process that includes a protective layer against UV radiation.

- Yes, steel strips can be used in the production of kitchen appliances. Steel is a common material used in the manufacturing of kitchen appliances due to its durability, strength, and resistance to heat and corrosion. Steel strips can be formed into various components and parts such as panels, frames, and shelves, making them suitable for use in kitchen appliances like ovens, refrigerators, and dishwashers.

- Steel strips are highly reliable and perform exceptionally well in high-pressure applications. Due to their inherent strength and durability, they can withstand the extreme forces and maintain structural integrity, making them ideal for various industries such as oil and gas, aerospace, and automotive. Additionally, steel strips offer excellent resistance to corrosion and temperature fluctuations, further enhancing their performance in high-pressure environments.

- The environmental impacts of steel strip manufacturing can be significant. Firstly, the extraction of iron ore, which is the main raw material used in steel production, can lead to deforestation, habitat destruction, and loss of biodiversity. The process of mining also requires large amounts of energy and water, contributing to greenhouse gas emissions and water pollution. Once the iron ore is extracted, it undergoes smelting and refining processes, which release substantial amounts of carbon dioxide and other greenhouse gases. These emissions contribute to climate change and air pollution. Additionally, the smelting process creates slag, a waste product that can contaminate soil and water if not properly managed. During the manufacturing process, steel strip production involves high energy consumption, mainly from fossil fuels. This energy consumption contributes to carbon emissions and further exacerbates climate change. Moreover, the production of steel strip requires the use of chemicals and coatings, which can result in the release of harmful substances into the environment. Furthermore, the disposal of waste generated during steel strip manufacturing, such as sludge and other by-products, can pose a threat to water sources and ecosystems if not properly treated or disposed of. These waste products often contain heavy metals and other pollutants that can contaminate soil and water, affecting both human and environmental health. Overall, the environmental impacts of steel strip manufacturing encompass various aspects, including deforestation, habitat destruction, greenhouse gas emissions, air pollution, water pollution, and waste generation. It is crucial for the industry to adopt more sustainable practices, such as using renewable energy sources, implementing recycling programs, and minimizing the use of harmful chemicals, in order to mitigate these impacts and promote a greener steel manufacturing process.

- There are several standards and certifications that are applicable to steel strips, ensuring their quality, safety, and compliance with industry regulations. Some of the key standards and certifications include: 1. ASTM International Standards: ASTM A109, ASTM A240, ASTM A568, and ASTM A1018 are widely recognized standards for steel strips. These standards specify the requirements for various steel grades, dimensions, tolerances, mechanical properties, and chemical compositions. 2. ISO Standards: ISO 9001 is a globally recognized quality management system (QMS) certification that ensures consistent product quality, customer satisfaction, and continuous improvement. ISO 14001 is an environmental management system (EMS) certification that focuses on minimizing the environmental impact of the production processes. 3. EN Standards: European standards such as EN 10130, EN 10139, EN 10268, and EN 10152 define the technical specifications for cold-rolled and hot-rolled steel strips. These standards cover aspects like surface finish, dimensional tolerances, mechanical properties, and chemical compositions. 4. JIS Standards: Japanese Industrial Standards (JIS) like JIS G3131, JIS G3141, JIS G3311, and JIS G4801 are widely used in the steel industry. These standards provide specifications for steel strips used in various applications, including automotive, construction, and electrical industries. 5. SAE Standards: The Society of Automotive Engineers (SAE) has established various standards for steel strips used in automotive applications. These standards ensure the suitability of the steel strips for specific automotive components, considering factors like strength, ductility, and formability. 6. PED Certification: The Pressure Equipment Directive (PED) certification is necessary for steel strips used in pressure vessels and related equipment. This certification ensures compliance with safety requirements and quality standards for pressure equipment used in various industries. 7. RoHS Compliance: Restriction of Hazardous Substances (RoHS) is a certification that restricts the use of certain hazardous substances in electrical and electronic equipment, including steel strips used in such applications. This certification ensures the safety of the end-users and compliance with environmental regulations. It is important for manufacturers, suppliers, and consumers to ensure that steel strips they use or purchase adhere to these standards and certifications. These standards and certifications guarantee the quality, reliability, and safety of steel strips for various applications.

- Steel strips perform well in corrosive environments due to their inherent resistance to corrosion. Steel is often coated with protective layers such as zinc, which further enhances its ability to withstand corrosion. Additionally, steel is known for its durability and strength, making it a reliable choice for applications in corrosive environments.

- Steel strips are commonly used in the production of signage as a durable and versatile material for creating sign frames, supports, and brackets. They provide strength and stability to the signage structure, allowing for easy installation and long-lasting performance. Steel strips can be shaped, bent, or welded to meet specific design requirements, ensuring that the signage remains sturdy and withstands various weather conditions. Additionally, steel strips can be coated or painted to enhance their visual appeal and protect against corrosion, making them a popular choice in the signage industry.