prepainted steel coil JIS G 3312

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

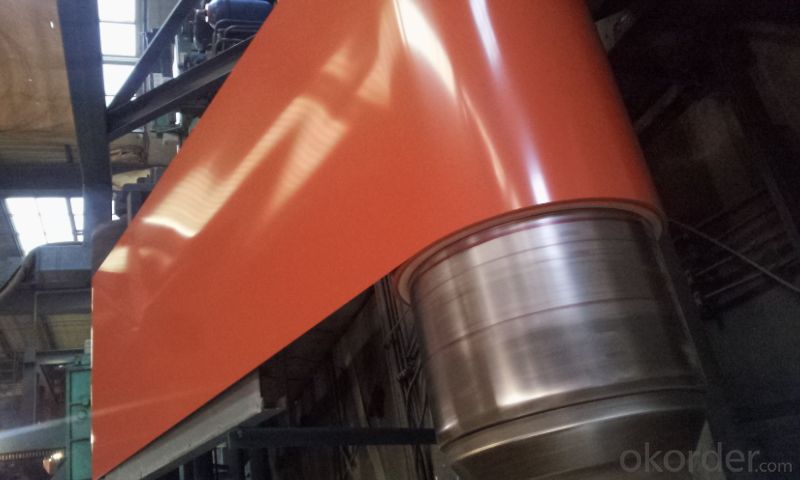

PREPAINTED STEEL COIL

Packaging & Delivery

Packaging Detail: seaworthy export package

Delivery Detail: on request

Specifications

1. more than 10 years’ experience on this field

2. advanced equipments

3. competitive price

4. soonest delivery

Product Description :

Commodity

PREPAINTED STEEL COIL

Technical Standard: JIS 3312

Grade:CGCC

Types:Commercial / Drawing / Deep Drawing / Structural quality

Width: 900mm/1000mm/1219mm/1200mm/1220mm/1250mm

Thickness: 0.2mm~4.0mm

Type of coating: galvanized

Zinc coating: Z40-275g/m2,Z40-Z450g/m2

ID coil: 508mm or 610mm

Coil weight: 3-10/MT per coil

Package:Properly packed for ocean freight exportation in 20''container

Application::home appliances, constructions, building, machineries

Our Advantages :

1. Expertise:

More than 10 years of manufacture: we know how to properly handle every step of production.

2. Competitive price:

We can offer competitive prices to our customers.

3. Accuracy:

We have excellent technicians and leaders, which can ensure our products are exactly what you want.

4. Materials:

All galvanized steel coils are made of high-quality raw materials.

5. Certificate:

Our products are certified by ISO9001.

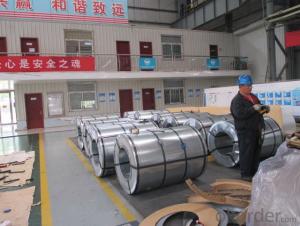

6. Productivity:

We have large-scales of production lines,, which can guarantee all your orders will be finished in earliest time.

Hr CGL Technical Process:

Coil loading-> uncoiling-> cutting-> welding-> entry accumulator-> Heating and deoxidization-> galvanizing-> air cooling->water quenching-> air dryer-> tension leveler-> Passivation->air dryer->exit accumulator-> oiling-> cutting-> recoiling->coil unloading-> packing

The furnace heating style: improved Sendzimir heating technology

Hourly output: max.76.3t/h

Process after coating: tension leveling, Passivation or oiling

Our Service

Our quality

Test Equipments of Prepainted Galvanized Steel Coil : Salt-spray tester; Atomic absorption spectrophotometer; Rockwell typer hardness tester; Tensile test machine; Metrohm titration; Laboratory Bend test machine.

Our packing

Properly packed for ocean freight exportation in 20''container, galvanized metal fluted rings on inner and outer edges, galvanized metal & waterproof paper wall protection disk, galvanized metal & waterproof paper around circumference.

R&D department

R&D department concentrates on researching and developing reliable products with best quality. The quality department test and control every process of production to guarantee the best quality of product

- Q: How are steel strips used in the production of automotive components?

- Steel strips are widely used in the production of automotive components due to their strength, durability, and versatility. These strips are typically made from high-quality steel alloy and come in various thicknesses and widths to suit different manufacturing requirements. One common application of steel strips in automotive production is for the fabrication of body panels. These strips are often stamped or pressed into shape using specialized machinery to create components such as doors, hoods, roofs, and fenders. The high strength of steel allows for thinner panels, reducing the overall weight of the vehicle while maintaining structural integrity and safety. Steel strips are also commonly used in the production of suspension and chassis components. These strips can be cut, bent, and welded to form various parts such as brackets, brackets, and reinforcements. The strong and rigid nature of steel ensures that these components can withstand the heavy loads and stresses experienced by vehicles during operation. Furthermore, steel strips are used in the manufacturing of engine and transmission components. These strips can be formed into intricate shapes and then heat-treated or machined to achieve the desired strength and precision. Examples of such components include gears, shafts, valves, and crankshafts. The high wear resistance and heat resistance of steel make it an ideal material for these critical components that are subjected to extreme conditions. In addition to their mechanical properties, steel strips are also used for their corrosion resistance. Automotive components made from steel strips are often coated with protective layers such as zinc or paint to prevent rusting and ensure longevity. In summary, steel strips play a vital role in the production of automotive components due to their strength, durability, versatility, and corrosion resistance. They are used in various applications ranging from body panels to suspension and engine components, contributing to the overall performance, safety, and longevity of vehicles.

- Q: Are steel strips commonly used in the automotive industry?

- Yes, steel strips are commonly used in the automotive industry. They are frequently employed in various applications such as body panels, chassis components, and suspension parts due to their high strength, durability, and cost-effectiveness.

- Q: What are the common surface treatment methods for steel strips?

- There are several common surface treatment methods for steel strips, each serving specific purposes and providing various benefits. One widely used method is galvanizing, which involves coating the steel strip with a layer of zinc. This process helps protect the steel from corrosion, as the zinc acts as a sacrificial anode and prevents oxidation. Galvanized steel strips are commonly used in outdoor applications where they are exposed to moisture and harsh weather conditions. Another common surface treatment method is electroplating, which involves depositing a thin layer of metal onto the steel strip's surface through an electrochemical process. This method is often used to enhance the appearance of the steel strip, provide a decorative finish, or improve its resistance to corrosion. Phosphating is another surface treatment method used for steel strips. It involves the application of a phosphate coating to the steel surface, which helps improve its adhesion to paints, lubricants, or other coatings. Phosphating can also enhance the steel strip's corrosion resistance and provide better wear resistance. Coating steel strips with a layer of paint or other organic coatings is also a common surface treatment method. This process can protect the steel strip from corrosion, provide a decorative finish, or serve as a primer for subsequent coatings. Finally, shot blasting is a surface treatment method that involves propelling small abrasive particles at high speeds onto the steel strip's surface. This process helps remove rust, scale, or other contaminants, and prepares the steel strip for further treatment or coating. Overall, these surface treatment methods for steel strips aim to enhance their appearance, protect them from corrosion, improve their adhesion properties, and increase their durability for various applications.

- Q: What are the different methods for grinding steel strips?

- There are several methods that can be used for grinding steel strips, depending on the desired outcome and the specific requirements of the project. Some of the most common methods include: 1. Surface grinding: This method involves using a horizontal rotary table machine with a grinding wheel to remove material from the surface of the steel strip. It is often used to achieve a smooth and flat surface finish. 2. Blanchard grinding: Blanchard grinding is a type of surface grinding that uses a vertical spindle machine with a rotating magnetic chuck to remove material. It is particularly effective for grinding large steel strips or parts with a high stock removal rate. 3. Centerless grinding: In centerless grinding, the steel strip is fed between two grinding wheels, one of which is stationary and the other rotating. This method is often used for grinding cylindrical steel strips with a consistent diameter. 4. Belt grinding: Belt grinding utilizes a sanding belt with abrasive particles to remove material from the steel strip. It is commonly used for deburring, polishing, and shaping the edges of steel strips. 5. Precision grinding: Precision grinding is a method that involves using specialized grinding machines and techniques to achieve extremely tight tolerances and precise dimensions. This method is often used for high-precision applications where accuracy is paramount. 6. Cylindrical grinding: Cylindrical grinding involves using a cylindrical grinder to grind the outer surface of the steel strip. This method is commonly used for producing cylindrical steel strips with a specific diameter or for achieving a specific surface finish. These are just a few of the different methods that can be used for grinding steel strips. The choice of method will depend on factors such as the desired outcome, the specific requirements of the project, and the type of steel being worked on. It is always important to carefully consider these factors and consult with a professional before selecting a grinding method.

- Q: How are steel strips heat-treated for specific applications?

- Steel strips are heat-treated for specific applications by subjecting them to controlled heating and cooling processes. This involves heating the steel strips to a specific temperature and holding it there for a predetermined amount of time. The strips are then rapidly cooled, or quenched, to achieve the desired hardness, strength, or other mechanical properties. The heat treatment process can also involve tempering or annealing to further refine the steel's properties. Overall, the goal is to tailor the steel strips' microstructure to meet the specific requirements of the intended application.

- Q: What is the length tolerance of steel strips?

- The length tolerance of steel strips can vary depending on the specific type and grade, but generally it is around ± 0.2% to ± 0.5% of the specified length.

- Q: What are the factors that affect the thermal conductivity of steel strips?

- The thermal conductivity of steel strips can be influenced by various factors. 1. One factor is the composition of the steel strip. The chemical composition plays a significant role in determining the thermal conductivity. Different steel alloys have different thermal conductivities. For example, stainless steel generally has higher thermal conductivity compared to carbon steel. 2. Another factor is the temperature. The thermal conductivity of steel strips can change with temperature. Normally, the thermal conductivity of metals decreases as the temperature rises. However, other factors like alloy composition and impurities can also affect this relationship. 3. The microstructure of the steel strip is also important. The arrangement of atoms and crystal defects in the microstructure can impact the thermal conductivity. A more uniform and compact microstructure tends to have higher thermal conductivity than a microstructure with impurities or defects. 4. The grain size of the steel strip can also affect thermal conductivity. Finer grain sizes enhance thermal conductivity as they provide a continuous path for heat transfer throughout the material. 5. Impurities, such as sulfur or phosphorus, can reduce the thermal conductivity of steel strips. These impurities act as barriers to heat transfer, hindering the flow of thermal energy through the material. 6. The surface finish of the steel strip can influence thermal conductivity. A smooth surface finish allows for better contact and heat transfer between the strip and other objects it comes into contact with, resulting in higher thermal conductivity. 7. The thickness of the steel strip is another factor to consider. Thicker strips tend to have lower thermal conductivity due to the increased distance heat has to travel through the material. 8. The heat treatment process used on the steel strip can alter its thermal conductivity. Different heat treatment methods can modify the microstructure and overall thermal properties of the steel, thus affecting its thermal conductivity. Considering these factors is important when selecting and using steel strips for applications that require specific thermal conductivity properties.

- Q: How do steel strips contribute to vibration damping in various applications?

- Steel strips contribute to vibration damping in various applications because of their high density and stiffness. When attached or integrated into structures, they absorb and dissipate the energy generated by vibrations, reducing their amplitude and frequency. This helps to minimize unwanted noise, prevent structural damage, and enhance overall stability and performance in applications such as machinery, automotive, and construction. The steel strips act as a damping material, converting mechanical energy into heat, thereby attenuating vibrations and improving the overall comfort, safety, and efficiency of the system.

- Q: How are steel strips inspected for surface defects?

- Steel strips are inspected for surface defects using various methods such as visual inspection, magnetic particle inspection, eddy current testing, and ultrasonic testing. These techniques help identify any imperfections, such as cracks, scratches, or pits, on the surface of the steel strips, ensuring their quality and integrity.

- Q: How do steel strips respond to different corrosion environments?

- Factors such as the type of corrosion, the composition of the steel, and the surrounding conditions can result in varying responses of steel strips to different corrosion environments. When exposed to moisture, oxygen, and aggressive chemicals, steel strips are generally susceptible to corrosion. However, the extent of corrosion can differ depending on the specific environment. In a dry environment with low humidity, significant corrosion of steel strips is less likely. Instead, a superficial layer of rust may develop, which does not affect the steel's structural integrity and can be easily removed. In a humid environment, steel strips are more prone to corrosion. Moisture in the air can cause rust to form on the surface of the steel, leading to deterioration and eventual failure if not addressed. In marine or saltwater environments, the presence of chloride ions makes steel strips highly susceptible to corrosion. These ions can penetrate the protective oxide layer on the steel's surface, accelerating the corrosion process and causing localized damage. Chemicals and industrial atmospheres can also contribute to the corrosion of steel strips. Exposure to acids, alkaline substances, or corrosive gases can result in destructive chemical corrosion, with the severity depending on concentration, temperature, and exposure duration. To prevent corrosion, protective measures can be taken. Coating steel strips with paint or galvanization creates a barrier against moisture and corrosive elements. Regular maintenance, including cleaning, inspection, and anti-corrosion treatments, can prolong the lifespan of steel strips in different corrosion environments. Overall, multiple factors influence how steel strips respond to corrosion environments, and proper prevention and maintenance practices are crucial to minimize the impact of corrosion and ensure the longevity of the steel strips.

Send your message to us

prepainted steel coil JIS G 3312

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords