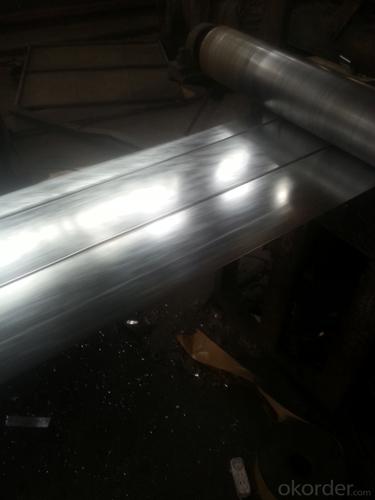

Hot Dip Galvanized Steel Strip

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Galvanized steel strips are widely used in the construction industry, as raw material for the production of corrugated panels, fencing products, drywall panel profiles, ventilation systems etc. Recommended for both outside and inside usage, galvanized steel has a high resistance to corrosion in different environments, due to a protective layer of zinc of 100 –180 grams per square metre.

Hotdip galvanized steel strips are produced by immersing steel in a zinc bath. An appropriate galvanizing process requires a pretreatment process during which the steel passes through different baths which prepare the surface for zinc coating. In this stage, chemicals are used to clean the surface of the steel. After the chemical treatment, the steel coils pass through a bath of melted zinc at temperatures around 460 ° C. The resulting uniform coating is finished through a process of skin-passing to provide smooth and shiny appearance of the finished product. To store for a longer period, the hot-dip galvanized coils can be delivered with a final oil coating, according to the customer’s demand.

Technical specification :

• Steel grade: DX51D+Z• Zinc coverage:30-180 g/sqm on both sides (depending by the requested specification);• Thickness: between 0,2 mm and 1,00 mm;• Width:600mm,914mm,1000mm, 1220mm and 1250 mm;• Coil weight: 4-6 mt;• Coil ID: 508 mm;• Coil OD: 900-1500 mm ;

Depending on their usage, the hot-dip galvanized coil can be delivered slightly oiled.

- Q: How are steel strips processed for fastening?

- Steel strips are processed for fastening through various methods such as cutting, shaping, and joining. These processes involve techniques like shearing, stamping, bending, and welding to create the desired shape and form of the steel strips. Additionally, surface treatments such as galvanization or coating may also be applied to enhance their durability and resistance to corrosion. Overall, the processing of steel strips for fastening involves a combination of mechanical and chemical processes to ensure their optimal performance in various applications.

- Q: What are the common surface finishes for steel strips to improve corrosion resistance?

- The common surface finishes for steel strips to improve corrosion resistance include galvanizing, electroplating, powder coating, and painting.

- Q: How are steel strips tested for coating adhesion?

- Steel strips are typically tested for coating adhesion through various methods such as cross-cut tests, pull-off tests, and bend tests. These tests involve assessing the ability of the coating to adhere to the steel surface by subjecting it to different forces and examining any signs of detachment or peeling.

- Q: Can steel strips be used for making conveyor belts?

- Yes, steel strips can be used for making conveyor belts. Steel strips offer several advantages for conveyor belt applications. Firstly, steel strips are durable and have high tensile strength, making them suitable for handling heavy loads and withstanding harsh operating conditions. They can resist impact, abrasion, and wear, ensuring a longer lifespan for the conveyor belt. Moreover, steel strips provide excellent stability and dimensional accuracy, which is crucial for maintaining proper tracking and alignment of the conveyor belt. Additionally, steel strips can be easily joined together to create a continuous belt, allowing for seamless material transportation. Overall, steel strips are a popular choice for conveyor belt manufacturing due to their strength, durability, and versatility.

- Q: What is the price of steel strips?

- The price of steel strips can vary depending on various factors such as the specific type of steel, the thickness and width of the strips, the quantity being purchased, and the current market conditions. It is best to consult with steel suppliers or manufacturers to get an accurate and up-to-date price quote for steel strips.

- Q: Are steel strips cost-effective compared to other materials?

- Yes, steel strips can be considered cost-effective compared to other materials for various applications. Steel is a versatile material that offers several advantages such as high strength, durability, and resistance to corrosion. These qualities make steel strips suitable for a wide range of industries, including construction, automotive, manufacturing, and infrastructure. In terms of cost, steel strips can be a cost-effective choice due to their long lifespan and low maintenance requirements. Steel is highly durable and can withstand harsh environments, reducing the need for frequent repairs or replacement. This longevity can result in significant cost savings over time. Additionally, steel is readily available and has a consistent supply, which helps maintain its affordability. The production processes for steel have become more efficient over the years, further contributing to its cost-effectiveness. Furthermore, steel strips can be easily fabricated and customized to meet specific project requirements, reducing wastage and optimizing resource allocation. This flexibility adds to the overall cost-effectiveness of using steel strips. However, it is essential to consider specific project requirements, such as the desired application, budget, and environmental factors, before determining the cost-effectiveness of steel strips compared to other materials. Each material has its own unique characteristics and associated costs, so a thorough analysis should be conducted to ensure the most suitable and cost-effective choice is made.

- Q: How are steel strips used in the production of metal grilles and screens?

- Due to their durability and versatility, steel strips find widespread use in the production of metal grilles and screens. These strips are typically cut to specific lengths and widths, and subsequently shaped and welded to create the desired pattern or design of the grille or screen. By providing strength and stability, steel strips enable the final product to withstand various environmental factors and frequent use. The strips are also treated to enhance their resistance to corrosion, ensuring longevity and durability. Moreover, steel strips can be easily manipulated and molded into different shapes and sizes, facilitating the creation of intricate and customized designs. This makes them a popular choice for manufacturers aiming to offer a diverse range of options to their customers. Additionally, steel strips can be coated or painted in various colors and finishes, enhancing the aesthetic appeal of the grilles and screens. This allows them to seamlessly blend with the overall design of a building or space. In summary, steel strips are vital components in the production of metal grilles and screens, as they provide strength, stability, durability, and customization options. Their contribution to the functionality and aesthetic appeal of these products makes them indispensable in the manufacturing process.

- Q: What are the different surface painting options for steel strips?

- Some of the different surface painting options for steel strips include powder coating, electrostatic painting, and galvanized coating. These options offer various levels of durability, resistance to corrosion, and aesthetic appeal.

- Q: What is the cost range of steel strips?

- The cost range of steel strips can vary depending on various factors such as the thickness, width, length, and grade of the steel. Generally, the price of steel strips can range from $0.50 to $3.00 per pound. However, it is important to note that this is just a rough estimate and prices can significantly fluctuate based on market conditions, supplier, and quantity. It is recommended to contact steel suppliers or manufacturers directly to get accurate and up-to-date pricing information.

- Q: Are steel strips suitable for the manufacturing of electrical components?

- Yes, steel strips are suitable for the manufacturing of electrical components due to their high strength, durability, and conductivity properties. They can be easily shaped and formed into various shapes and sizes required for electrical components. Additionally, steel strips provide excellent electromagnetic shielding and are resistant to corrosion, making them suitable for long-lasting and reliable electrical products.

Send your message to us

Hot Dip Galvanized Steel Strip

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords