Stainless Steel Coil SS 201/304/316/304L/316L/309S/310S/430 stainless steel coil

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Stainless Steel Coil Description

The surface brightness and flatness of no2B is better than no2D. then through a special

surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses.

2.Main Features of the Stainless Steel Coil

• Tensile strength: not less than 520

• Provides that non-proportional extension strength: not less than 205

• Elongation: not less than 35; 3 density: 7.98

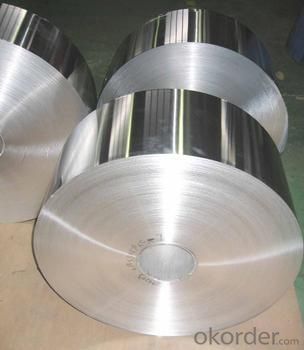

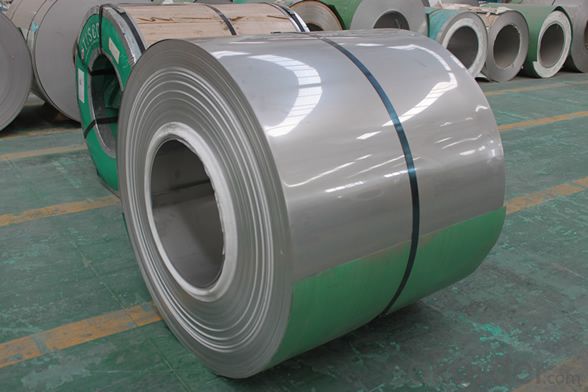

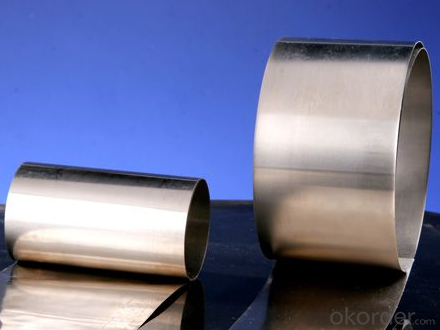

3. Stainless Steel Coil Images

4. Stainless Steel Coil Specification

| Grade: | 200series.300series. | Standard: | JIS,AISI,ASTM | Length: | as request |

| Thickness: | 0.3-3mm | Width: | 30-2000mm | Place of Origin: | Shanxi China (Mainland) |

| Brand Name: | CNBM | Model Number: | ss201/304/316/304L/316L/309S/310S/430 | Type: | Coil |

| Application: | hardware, foodstuff, manufacture, medic | Certification: | SGS | Item: | ss202/304/316/309s/310/410/420 stainless steel sheet |

| Packaging: | Export standard package or as your requirement | Delivery: | In 15 days | Stock: | Available |

5.FAQ of Stainless Steel Coil

①Who are you?

We are the manufacturer! We produce stainless steel products

with high quality & very competitive price!Please feel free to

contact us for more information!

②How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

③How about your company?

A world class manufacturer & supplier of castings forging in Stainless Steel Sheet,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

- Q: What are the different joining methods for steel strips?

- There are several different joining methods for steel strips, including welding, soldering, brazing, and mechanical fastening.

- Q: Reasons for black side of hot strip galvanizing

- Luoyang Taihong hot galvanizing factory to tell you the reason, the emergence of the black side of reason is generally divided into: contains too much iron impurities of galvanized steel strip into the liquid, thus causing blackening; resulting in the high current hot galvanized steel blackening;

- Q: Can steel strips be used in the production of kitchen utensils?

- Yes, steel strips can be used in the production of kitchen utensils. Steel is a popular choice for kitchen utensils due to its strength, durability, and resistance to corrosion. Steel strips are commonly used as the raw material for manufacturing various kitchen utensils such as knives, spoons, forks, spatulas, and tongs. These strips can be shaped, formed, and forged into the desired utensil shapes and sizes. Steel strips also provide a smooth and hygienic surface, making them ideal for food handling and cooking purposes. Additionally, steel utensils are easy to clean and maintain, making them a preferred choice in many kitchens.

- Q: How are steel strips used in the manufacturing of pneumatic systems?

- Steel strips are commonly used in the manufacturing of pneumatic systems due to their various advantageous properties. These strips are typically made from high-quality steel, which ensures durability and strength, making them suitable for the demanding requirements of pneumatic applications. In the manufacturing process of pneumatic systems, steel strips are primarily used for the fabrication of essential components such as brackets, clamps, and supports. These components play a crucial role in providing structural support, stability, and alignment to the pneumatic system. For instance, steel strips can be formed into brackets that hold different pneumatic elements together, such as cylinders, valves, and filters. These brackets ensure the proper positioning and secure attachment of these elements, preventing any misalignment or movement that could affect the functionality of the system. Similarly, steel strips can be shaped into clamps that securely hold pneumatic hoses or tubes in place. These clamps prevent the hoses or tubes from dislodging or getting tangled, ensuring the smooth flow of compressed air or other gases within the system. Moreover, steel strips are also used in the manufacturing of supports, which provide additional reinforcement and stability to the overall structure of the pneumatic system. These supports are particularly important in larger and more complex pneumatic setups, where the weight and distribution of components require extra strength and rigidity. In summary, steel strips are an integral part of the manufacturing process for pneumatic systems. They are used to create brackets, clamps, and supports that provide structural support, stability, and alignment to the various components of the system. The durability and strength of steel strips make them an ideal material choice for these critical applications.

- Q: How are steel strips processed for sustainability?

- Various methods and practices are employed to ensure the sustainable processing of steel strips, with the goal of minimizing environmental impact and promoting resource efficiency. A key process involves using recycled steel as a raw material. By reusing scrap steel and transforming it into new steel strips, the need for extracting virgin iron ore is reduced, leading to significant energy savings and decreased carbon emissions. Furthermore, steel manufacturers are increasingly embracing energy-efficient technologies and practices to reduce their carbon footprint. For example, during steel strip processing, energy-saving furnaces and advanced heating systems are utilized to optimize energy consumption and minimize waste heat. This not only reduces energy usage but also decreases the emission of greenhouse gases. Water conservation is also crucial in the sustainable processing of steel strips. By implementing water recycling and reuse systems, steel manufacturers can minimize water consumption and alleviate pressure on local water resources, particularly in regions facing water scarcity concerns. Moreover, efficient production techniques are employed to minimize material waste during the processing of steel strips. Advanced cutting and shaping technologies help optimize the use of materials, thereby reducing the amount of steel wasted during the manufacturing process. Waste management systems are also in place to ensure proper disposal or recycling of any leftover materials. Furthermore, steel manufacturers are increasingly prioritizing the reduction of air pollution associated with steel strip processing. Advanced air filtration systems and emission control technologies are utilized to capture and treat pollutants before they are released into the atmosphere. This not only improves air quality but also mitigates the impact on surrounding communities. Overall, the steel industry is actively striving to process steel strips in a sustainable manner. By incorporating recycled materials, adopting energy-efficient technologies, conserving water, minimizing waste, and reducing air pollution, steel manufacturers are working towards a future that is both environmentally and socially responsible. These practices not only contribute to the preservation of the environment but also contribute to the development of a more efficient and socially conscious steel industry.

- Q: Can steel strips be used in the production of roofing materials?

- Indeed, roofing materials can benefit from the utilization of steel strips. Steel, a robust and long-lasting substance, is frequently employed in construction, particularly for roofing purposes. It is common to employ steel strips as the foundation for roofing panels or sheets. Typically, these strips receive a protective coating, such as zinc or a blend of zinc and aluminum, to bolster their resistance against corrosion and extend their lifespan. Moreover, steel strips can be molded into diverse shapes and profiles to meet the specific demands of various roofing systems. In summary, steel strips provide numerous advantages for roofing materials, encompassing strength, durability, and adaptability.

- Q: How are steel strips used in the production of automotive chassis components?

- Steel strips are commonly used in the production of automotive chassis components due to their strength, durability, and versatility. These strips are shaped and welded together to form the framework of the vehicle, providing structural support and ensuring the safety and stability of the chassis. Additionally, steel strips can be easily manipulated and formed into various shapes, allowing for the customization of chassis components to meet specific design requirements.

- Q: How are steel strips used in the production of metal fences?

- Metal fences rely on steel strips as a vital ingredient in their manufacturing process. These strips are typically crafted from top-notch steel that possesses high durability and resistance against corrosion, making them well-suited for outdoor usage. Within the production process, steel strips serve to construct the skeleton or framework of the metal fence. They are trimmed to the necessary dimensions and molded into various sections, such as posts, rails, and pickets. This framework provides the fundamental strength and support required to withstand external forces, such as wind or impact. Furthermore, steel strips may also be employed to fortify the connection points of the fence. They can be either welded or bolted onto the framework to amplify stability and eliminate any potential weak spots. This reinforcement guarantees the fence's stability and security. Moreover, steel strips can also be utilized to amplify the visual appeal of the metal fence. They can be shaped into decorative patterns or designs, adding a visually pleasing component to the overall appearance of the fence. These strips may also be utilized as ornamental features on the top or between sections of the fence, further enhancing its aesthetics. In summary, steel strips occupy a vital role in the production of metal fences. They offer the necessary strength, durability, and support required to create a robust and long-lasting fence. Additionally, they contribute to the visual allure of the fence, making it an attractive choice for both residential and commercial applications.

- Q: What are the different surface finishes available for steel strips?

- Some of the different surface finishes available for steel strips include mill finish, hot dip galvanized, electro-galvanized, painted, and coated finishes such as PVC coated or stainless steel coated. These finishes provide varying levels of protection against corrosion and can also enhance the appearance of the steel strips.

- Q: Can steel strips be used in the food industry?

- Yes, steel strips can be used in the food industry. Stainless steel strips are commonly used in the food industry due to their excellent corrosion resistance, durability, and hygienic properties. They are used in various applications such as food processing equipment, conveyor systems, storage tanks, and packaging machinery. Stainless steel strips are easy to clean and maintain, making them suitable for applications where hygiene and cleanliness are essential. Additionally, stainless steel is non-reactive to food substances, ensuring that the quality and taste of the food are not affected. Therefore, steel strips are a reliable and widely accepted material in the food industry.

Send your message to us

Stainless Steel Coil SS 201/304/316/304L/316L/309S/310S/430 stainless steel coil

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords