cold rolled steel coil DC03

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

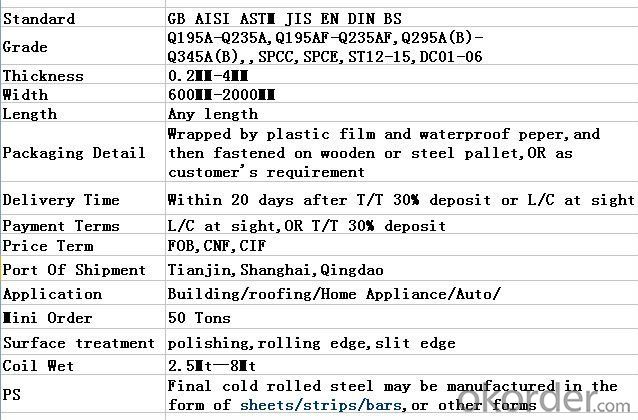

Packaging & Delivery

| Packaging Detail: | Wrapped by plastic film and waterproof peper,and then fastened on wooden or steel pallet,OR as customer's requirement |

| Delivery Detail: | Within 20 days after T/T 30% deposit or L/C at sight |

Specifications

Cold rolling / cold rolled sheet / cold rolled roils / cold rolled plate

Q195A-Q345A,,SPCC,SPCD,SPCE,ST12-15,DC01-06

- Q: Can steel strips be used in the manufacturing of agricultural equipment?

- Yes, steel strips can be used in the manufacturing of agricultural equipment. Steel strips provide strength, durability, and resistance to corrosion, making them suitable for various applications in agricultural machinery such as plows, cultivators, harvesters, and seeders.

- Q: Can steel strips be used in the construction of storage tanks?

- Yes, steel strips can be used in the construction of storage tanks. Steel is a commonly used material in tank construction due to its high strength, durability, and ability to withstand extreme temperatures and pressures. Steel strips can be formed, welded, and reinforced to create the necessary shape and structure for storage tanks, making them a reliable choice for such applications.

- Q: How are steel strips used in the production of solar panels?

- Integral to the production process of solar panels are steel strips. These strips serve primarily as frames and structural supports for the panels. They are typically crafted from galvanized steel, which is renowned for its durability and resistance to corrosion. To form the framework of the solar panel, specific lengths and shapes are cut into the steel strips. This framework holds all the panel components together, including the glass cover, solar cells, and backsheet. To ensure panel stability, especially during installation and exposure to diverse weather conditions, the steel strips are securely fastened. Furthermore, the steel strips play a crucial role in maintaining the overall integrity of the solar panel. They serve as a protective barrier, shielding the delicate components from external forces like wind, rain, and snow. By providing structural support, the steel strips prevent damage and ensure the panel's longevity. Moreover, the steel strips are indispensable for the installation and mounting of solar panels. They are used to firmly secure the panels onto rooftops or other surfaces. This ensures that the panels are securely fixed in place, maximizing exposure to sunlight and optimizing energy production. In conclusion, steel strips are a vital component in the production of solar panels. They provide structural support, maintain panel integrity, and facilitate installation and mounting. By incorporating steel strips into the manufacturing process, solar panels become more robust, reliable, and efficient, contributing to the overall sustainability and effectiveness of solar energy systems.

- Q: Can steel strips be used in the oil and gas industry?

- Yes, steel strips can be used in the oil and gas industry. They are commonly used for various applications such as pipelines, storage tanks, and offshore platforms due to their strength, durability, and resistance to corrosion.

- Q: Can steel strips be used for making musical instruments?

- Yes, steel strips can be used for making musical instruments. They are commonly used in instruments such as steel drums, steel guitars, and some percussion instruments. The steel strips are shaped, tuned, and played in different ways to produce specific musical notes and tones.

- Q: How are steel strips used in the production of metal staircases?

- Steel strips are commonly used in the production of metal staircases as they provide structural support and reinforcement. These strips are typically attached to the staircase framework to enhance its strength and stability. Additionally, they can be used to create the steps themselves, adding durability and longevity to the staircase design.

- Q: What are the different surface engraving methods for steel strips?

- There are several different surface engraving methods for steel strips, including laser engraving, chemical etching, mechanical engraving, and electrochemical etching.

- Q: What are the specifications for steel strips used in the production of conveyor belts?

- The production of conveyor belts requires different specifications for the steel strips, which can vary depending on the specific needs of the application. However, there are some general specifications commonly used in the industry. 1. Material: High-quality carbon steel or stainless steel is typically used for the steel strips in conveyor belts. Carbon steel is more commonly used due to its strength and cost-effectiveness, although stainless steel may be preferred in applications where corrosion resistance is crucial. 2. Thickness: The desired strength and durability of the conveyor belt determine the thickness of the steel strip. The thickness usually ranges from 0.4mm to 3mm, although thicker strips may be used for heavy-duty applications. 3. Width: The width of the steel strip is determined by the width of the conveyor belt itself. It can vary from a few centimeters to several meters, depending on the specific application. 4. Surface Finish: The surface finish of the steel strip can be plain or coated. Coatings such as zinc or chrome may be applied to enhance the strip's corrosion resistance. 5. Tensile Strength: The steel strip's tensile strength is a crucial specification as it determines the maximum load the conveyor belt can handle. Typical tensile strength ranges from 500 MPa to 1500 MPa, depending on the application. 6. Hardness: The wear resistance of the steel strip is influenced by its hardness. In high-wear applications, hardened strips are often used to improve the conveyor belt's longevity. 7. Edge Condition: The edges of the steel strip can be either slit or deburred. Slit edges are more commonly used as they provide a smoother surface for the conveyor belt to run on. It is important to note that these specifications are not exhaustive and may vary depending on the specific requirements of the conveyor belt application. For more detailed and customized specifications, consulting a steel strip manufacturer or conveyor belt supplier is recommended.

- Q: What is the maximum width of steel strips?

- The maximum width of steel strips has the potential to fluctuate based on various factors, including the manufacturing process and the capabilities of the equipment utilized. Nevertheless, in broad terms, the width of steel strips can span from a few inches to numerous feet. The precise measurements shall be contingent upon the particular demands of the industry or application in which the steel strips are employed.

- Q: How are steel strips used in the production of pipes and tubes?

- The production of pipes and tubes relies heavily on steel strips, which serve as a vital component. These strips act as the raw material and undergo various manufacturing processes to achieve the desired shape and size. To begin with, the steel strips are unwound and introduced into a forming machine, where they undergo a continuous bending process. This process entails passing the strips through a sequence of rollers, gradually shaping them into a cylindrical form. By adjusting the distance between the rollers, control can be exerted over the diameter and thickness of the pipes or tubes. Once the strips have taken on the desired shape, they are joined together along their length to create a seamless or welded connection. For seamless pipes, the ends of the strip are subjected to high-frequency induction welding or electric resistance welding techniques, causing them to be heated and fused together. Conversely, welded pipes are formed by welding the edges of the strip using various methods, such as high-frequency induction welding, electric arc welding, or submerged arc welding. Following the welding process, additional steps may be taken to enhance the properties of the pipes or tubes. These steps can include heat treatment, surface treatment, or sizing, all of which are carried out to meet specific requirements, such as strength, durability, corrosion resistance, or aesthetic appearance. In summary, steel strips play a crucial role in the production of pipes and tubes by serving as the foundational material that is shaped and welded to achieve the desired shape and size. The versatility and strength of steel make it an ideal choice for pipes and tubes in a wide range of industries, including construction, infrastructure, oil and gas, automotive, and manufacturing.

Send your message to us

cold rolled steel coil DC03

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords