All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What is the role of steel strips in the production of railroads and railway tracks?

Steel strips are an essential component in the production of railroads and railway tracks as they serve as the primary material for constructing the rails. These strips are shaped and formed to create the long, sturdy tracks that support the weight of trains, ensuring smooth and safe transportation. Steel strips provide durability, strength, and resistance to heavy loads and extreme weather conditions, making them crucial for the efficient functioning of railway systems.

What is the significance of phosphor bronze in specific steel strip applications?

Phosphor bronze is significant in specific steel strip applications primarily due to its unique combination of properties. It offers excellent corrosion resistance, high strength, good fatigue resistance, and superb electrical conductivity. These properties make phosphor bronze ideal for applications that require a strong and durable material while also being able to withstand harsh environmental conditions. Additionally, its electrical conductivity makes it suitable for applications that involve electrical connections or components. Overall, the significance of phosphor bronze in specific steel strip applications lies in its ability to provide a balance of strength, corrosion resistance, and electrical conductivity.

How are steel strips used in the production of components for railway and tram systems?

Steel strips are used in the production of components for railway and tram systems as they provide strength, durability, and stability. These strips are commonly used in the fabrication of various parts such as rails, tracks, and electrical components. They are also utilized in the manufacturing of structural elements like brackets, frames, and supports, ensuring the overall stability and safety of the railway and tram systems.

What are the tolerances for width and thickness in steel strips?

The tolerances for width and thickness in steel strips can vary depending on the specific requirements and industry standards. However, in general, the tolerances for width can range from +/- 0.005 to 0.030 inches, while the tolerances for thickness can range from +/- 0.001 to 0.010 inches. It is important to consult the relevant specifications or manufacturer guidelines for precise tolerances.

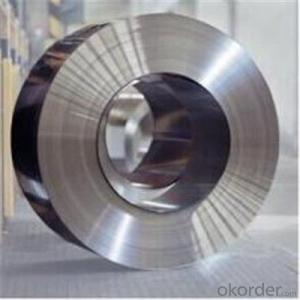

Wholesale Steel Strips from supplier in Bahrain

Whether you are in need of hot rolled steel strips, cold rolled steel strips, or galvanized steel strips, we have got you covered. Our steel strips are sourced from reputable manufacturers and undergo strict quality control measures to ensure that they meet the highest industry standards.

We understand that every project is unique, and our team of experienced professionals is committed to working closely with you to understand your specific requirements and provide customized solutions. We offer competitive prices, timely delivery, and excellent customer service to ensure your satisfaction.

In addition to our sales services, we also provide comprehensive technical support. Our team of experts is available to answer any questions you may have, provide technical specifications, and offer guidance on the best steel strip products for your application. We are committed to ensuring that you have all the information and support you need to make informed decisions.

As a subsidiary of CNBM, one of the largest building materials and equipment companies in the world, we have access to a vast network of suppliers and resources. This enables us to offer efficient and convenient procurement solutions, ensuring that you have access to the best steel strip products in Bahrain.

Contact us today to discuss your steel strip requirements and experience the difference of working with a leading supplier in Bahrain. We look forward to serving you and being a part of your success.

We understand that every project is unique, and our team of experienced professionals is committed to working closely with you to understand your specific requirements and provide customized solutions. We offer competitive prices, timely delivery, and excellent customer service to ensure your satisfaction.

In addition to our sales services, we also provide comprehensive technical support. Our team of experts is available to answer any questions you may have, provide technical specifications, and offer guidance on the best steel strip products for your application. We are committed to ensuring that you have all the information and support you need to make informed decisions.

As a subsidiary of CNBM, one of the largest building materials and equipment companies in the world, we have access to a vast network of suppliers and resources. This enables us to offer efficient and convenient procurement solutions, ensuring that you have access to the best steel strip products in Bahrain.

Contact us today to discuss your steel strip requirements and experience the difference of working with a leading supplier in Bahrain. We look forward to serving you and being a part of your success.