All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

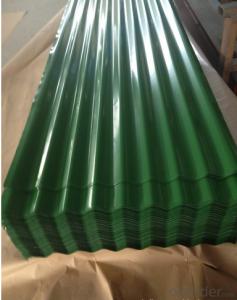

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How is coil temperature monitored and managed during the production process?

Coil temperature is typically monitored and managed during the production process using temperature sensors and control systems. These sensors are placed strategically on the coil or in the surrounding environment to measure the temperature accurately. The data collected from these sensors is then sent to a control system, which continuously monitors the temperature and makes necessary adjustments to maintain the desired temperature range. This control system can automatically regulate variables such as coolant flow, heating or cooling elements, or adjust the speed of the production process to manage the coil temperature effectively. Additionally, operators or engineers responsible for the production process may also visually monitor the coil temperature and manually intervene if required. Overall, a combination of sensors, control systems, and human supervision ensures that coil temperature is closely monitored and managed to ensure optimal production conditions.

How are steel coils tested for their fatigue resistance in heavy machinery?

Steel coils are typically tested for their fatigue resistance in heavy machinery through a process called fatigue testing. This involves subjecting the coils to repeated cycles of stress and strain, simulating the real-life conditions they would experience during operation. The coils are subjected to varying levels of load and strain, and their performance is closely monitored to determine their fatigue life and resistance. This testing helps ensure that the steel coils can withstand the high-stress conditions they will encounter in heavy machinery, thereby enhancing their reliability and durability.

What is the significance of coil cleanliness?

The significance of coil cleanliness is crucial for the optimal performance and efficiency of HVAC systems. Dirty coils, whether in air conditioners or refrigerators, hinder heat transfer and airflow, leading to reduced cooling capacity and increased energy consumption. Regular cleaning of coils helps maintain their effectiveness in removing heat from the air or refrigerant, ensuring efficient operation and cost savings. Additionally, clean coils also prevent the growth of mold, bacteria, and other contaminants, promoting better indoor air quality and a healthier environment.

Wholesale Steel Coils from supplier in Iran

Our team of experts is committed to delivering top-quality Steel Coils to our clients in Iran. We understand the specific requirements of the industry and offer a wide range of options to suit various applications. With our strong network of suppliers and manufacturers, we ensure timely delivery and competitive prices.

We provide sales and quotations for Steel Coils, ensuring transparency and cost-efficiency. Our dedicated customer support team is available to assist you with any queries or concerns you may have.

In addition to sales, we also offer technical support for Steel Coils. Our team of engineers and technicians provide guidance and assistance in choosing the right product for your projects. We understand the importance of choosing the right Steel Coils for optimal performance and durability.

As a subsidiary platform of CNBM, a Fortune Global 500 company, we have access to a vast pool of resources and expertise. This allows us to offer comprehensive procurement services for Steel Coils in Iran. We have established strong relationships with reputable suppliers and manufacturers, ensuring reliable and high-quality products.

Our years of experience in the market have enabled us to understand the evolving needs of our clients. We stay updated with the latest industry trends and technologies to provide innovative solutions for our customers. Whether you require Steel Coils for construction, manufacturing, or any other application, we are well-equipped to meet your needs.

Contact us today to discuss your requirements and let our team assist you in finding the perfect Steel Coils for your projects in Iran.

We provide sales and quotations for Steel Coils, ensuring transparency and cost-efficiency. Our dedicated customer support team is available to assist you with any queries or concerns you may have.

In addition to sales, we also offer technical support for Steel Coils. Our team of engineers and technicians provide guidance and assistance in choosing the right product for your projects. We understand the importance of choosing the right Steel Coils for optimal performance and durability.

As a subsidiary platform of CNBM, a Fortune Global 500 company, we have access to a vast pool of resources and expertise. This allows us to offer comprehensive procurement services for Steel Coils in Iran. We have established strong relationships with reputable suppliers and manufacturers, ensuring reliable and high-quality products.

Our years of experience in the market have enabled us to understand the evolving needs of our clients. We stay updated with the latest industry trends and technologies to provide innovative solutions for our customers. Whether you require Steel Coils for construction, manufacturing, or any other application, we are well-equipped to meet your needs.

Contact us today to discuss your requirements and let our team assist you in finding the perfect Steel Coils for your projects in Iran.