All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

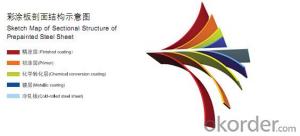

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How are steel strips integrated into the production of electromagnetic shielding materials?

Steel strips are integrated into the production of electromagnetic shielding materials by being layered or woven within the material to enhance its ability to block or redirect electromagnetic waves. This integration provides a conductive path for the electromagnetic fields, allowing the steel strips to absorb or reflect the waves, thus reducing or eliminating their impact on sensitive electronic devices.

What are the applications of steel strips in the manufacturing of conveyor belts?

Steel strips are used in the manufacturing of conveyor belts due to their high tensile strength, durability, and resistance to wear and tear. They provide the necessary support and stability for the conveyor belt, ensuring smooth movement of materials and efficient operation of the conveyor system. Additionally, steel strips offer excellent heat resistance, making them suitable for conveying hot materials.

What are the considerations in selecting steel strips for use in seawater corrosion environments?

When selecting steel strips for use in seawater corrosion environments, several considerations need to be taken into account. Firstly, the steel should have excellent corrosion resistance properties to withstand the harsh conditions of seawater exposure. Stainless steel, specifically grades such as 316 or Duplex stainless steels, are commonly used for this purpose due to their high resistance to corrosion.

Additionally, the steel strips should possess good strength and durability to prevent deformation or failure under the constant exposure to seawater. The mechanical properties of the steel, including tensile strength and hardness, should be carefully evaluated to ensure the strips can withstand the stresses of the environment.

Furthermore, it is important to consider the manufacturing process and surface treatment of the steel strips. Techniques such as hot rolling or pickling can affect the surface finish and corrosion resistance of the steel. Coatings or treatments like galvanization or epoxy coatings may also be applied to enhance the corrosion resistance of the steel strips.

Lastly, cost-effectiveness is also a consideration. The selected steel should provide a balance between its performance and cost, ensuring that it meets the required specifications without exceeding the budget.

Overall, the considerations in selecting steel strips for use in seawater corrosion environments involve evaluating corrosion resistance, mechanical properties, surface treatments, and cost-effectiveness to ensure long-term performance and durability.

Wholesale Steel Strips from supplier in Iran

Our team of experts is dedicated to understanding your specific requirements and providing tailored solutions to meet your needs. We offer a wide range of Steel Strips products, including hot-rolled steel strips, cold-rolled steel strips, galvanized steel strips, and stainless steel strips.

When you choose us as your supplier, you can expect competitive prices, high-quality products, and timely delivery. We work closely with reputable manufacturers to ensure that our Steel Strips products meet the highest industry standards. Additionally, our technical support team is always available to answer any questions and provide guidance throughout the procurement process.

Whether you are looking for Steel Strips for construction, manufacturing, or any other application, we have the expertise and resources to meet your requirements. Our commitment to customer satisfaction drives us to continuously improve our services and exceed your expectations.

Contact us today to discuss your Steel Strips needs in Iran and let us provide you with the best solutions for your projects.

When you choose us as your supplier, you can expect competitive prices, high-quality products, and timely delivery. We work closely with reputable manufacturers to ensure that our Steel Strips products meet the highest industry standards. Additionally, our technical support team is always available to answer any questions and provide guidance throughout the procurement process.

Whether you are looking for Steel Strips for construction, manufacturing, or any other application, we have the expertise and resources to meet your requirements. Our commitment to customer satisfaction drives us to continuously improve our services and exceed your expectations.

Contact us today to discuss your Steel Strips needs in Iran and let us provide you with the best solutions for your projects.