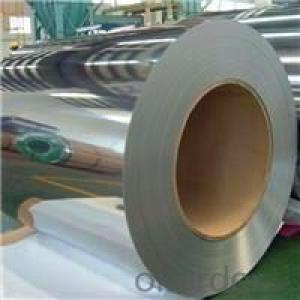

Cold Rolled Steel Strip Stainless Steel Strip Coils

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 100000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | cold rolled stainless steel strip coils is packed in export standard package |

| Delivery Detail: | cold rolled stainless steel strip coils finished within 15 days |

Specifications

1,cold rolled stainless steel strip coils thickness0.2~1.5mm

2.Ensure you quality timely deliver

3.2B finish

4.Tolerance 0.01

Item Details:

1, cold rolled stainless steel strip coils with thickness 0.2~1.5mm

2, Finishing: 2B

3, Width: 15~500mm

4. Tolerance: -0.01mm~0.01mm

Our advantage

1, High quality: Using lastest automated control equipment to ensure china stainless steel coil quality, such as AGC system.

2, Best Price: With most automated equipments to cost down.

3, Fast delivery: Since your order placed, ETD will be only 10 days.

4, Best Sevice: We do believe your encouragement is the best support for us.

Shipping information:

1, Payment terms: T/T 30% for depsoit, Balance against the copy of B/L; or L/C at sight

2, ETD: 10-15 days after the receipt of the deposit

3, Ship terms: FOB Ningbo

4, Minimum quantity: 5 tons

Contact and Feedback:

If you are interested in any of cold rolled stainless steel strip coils or any question, please feel free to contact us. We will reply you within 24H.

- Q: What is the thickness tolerance of steel strips?

- The thickness tolerance of steel strips can vary depending on the specific grade and manufacturing process. In general, the industry standard for steel strip thickness tolerance is typically +/- 10% of the specified thickness. However, it is important to note that different applications may have more stringent tolerance requirements. For instance, industries such as automotive or aerospace might require tighter thickness tolerances to ensure precise fit and performance. Therefore, it is crucial to consult the relevant industry standards or specifications to determine the specific thickness tolerance requirements for a particular steel strip application.

- Q: How are steel strips protected against rust?

- Steel strips are protected against rust through various methods such as applying a protective coating like galvanization or painting, using corrosion-resistant alloys, or through the process of hot-dip coating.

- Q: What are the different methods for welding steel strips?

- Welding steel strips can be accomplished through various methods, each with its own benefits and applications. Some commonly employed techniques are: 1. Arc Welding: This method employs an electric arc to generate heat and melt the steel strips. Different types of arc welding, like Shielded Metal Arc Welding (SMAW), Gas Metal Arc Welding (GMAW), and Flux-Cored Arc Welding (FCAW), offer versatility and suitability for different strip thicknesses. 2. TIG Welding: Tungsten Inert Gas (TIG) welding is widely used for steel strip welding. It employs a non-consumable tungsten electrode to create an arc, and filler material is added if necessary. TIG welding delivers high-quality and precise welds, making it ideal for delicate strips and critical applications. 3. MIG Welding: Metal Inert Gas (MIG) welding is a semi-automatic technique that utilizes a consumable wire electrode and inert gas to shield the weld pool. It is a fast and efficient process, well-suited for industrial applications involving steel strip welding. 4. Laser Welding: This non-contact method employs a powerful laser beam to melt and join the steel strips. Laser welding offers precise control and minimal heat input, resulting in narrow and clean welds. It is commonly used in industries like electronics and automotive for thin steel strips. 5. Resistance Welding: Resistance welding utilizes the heat generated from an electric current passing through the steel strips to join them. Spot welding, seam welding, and projection welding are different types of resistance welding. The automotive industry frequently employs this method to join steel strips together. 6. Plasma Arc Welding: Plasma arc welding is a variation of TIG welding that employs a focused plasma arc to melt the steel strips. It provides higher energy density compared to conventional TIG welding, enabling faster welding speeds and deeper penetration. Plasma arc welding finds applications in industries such as aerospace and shipbuilding, particularly for thicker steel strips. Overall, the selection of a welding method for steel strips depends on factors like strip thickness, desired weld quality, and specific application requirements. Each method offers unique advantages and should be chosen based on the project's specific needs.

- Q: What are the properties of steel strips?

- Steel strips typically possess several properties that make them highly versatile and widely used in various industries. Some key properties of steel strips include high strength, excellent durability, good corrosion resistance, and high heat resistance. They can also be easily shaped, formed, and welded, making them suitable for a range of applications such as automotive components, construction materials, and electrical appliances. Additionally, steel strips have a high weight-to-strength ratio, making them an ideal choice for lightweight structures.

- Q: How are steel strips waterjet cut?

- Steel strips are waterjet cut using a high-pressure stream of water mixed with an abrasive material. The waterjet machine precisely directs the stream onto the steel strip, eroding the material and creating a clean and accurate cut.

- Q: What is the typical thermal conductivity of steel strips?

- The typical thermal conductivity of steel strips is around 15-50 W/m·K.

- Q: How are steel strips formed into different shapes?

- Steel strips can be formed into different shapes through various processes such as bending, rolling, stamping, or pressing. These techniques apply pressure or force to manipulate the steel strip into the desired shape, allowing for the creation of a wide range of forms and structures.

- Q: What are the different slitting techniques for steel strips?

- There are several different slitting techniques for steel strips, including rotary shear slitting, loop slitting, and crush cutting. Rotary shear slitting involves using rotary knives to cut the steel strip into narrower widths. Loop slitting is a technique where the steel strip is passed through a series of loops to maintain tension while cutting. Crush cutting involves using a crush roller or knife to cut the steel strip. These techniques are used to create narrower steel strips for various industrial applications.

- Q: How are steel strips processed for surface texturing?

- Steel strips can be processed for surface texturing through various methods such as mechanical etching, shot blasting, or chemical etching. These processes involve altering the surface of the steel strips to create desired textures or patterns, enhancing their visual appeal and functional properties.

- Q: How do steel strips contribute to magnetic properties in various applications?

- The composition and processing of steel strips contribute significantly to their magnetic properties in various applications. Steel, an alloy primarily composed of iron with a small percentage of carbon and other elements, possesses crucial magnetic properties due to the presence of iron. As a ferromagnetic material, iron can be magnetized and retains its magnetism. The hardness and magnetic characteristics of steel are determined by its carbon content. Higher carbon content increases hardness but decreases magnetic properties. Therefore, steel strips used for magnetic applications are typically low carbon or have controlled carbon content. The magnetic properties of steel strips are also influenced by their processing. Annealing, for instance, involves heating the steel strips and slowly cooling them to relieve stress and refine the grain structure. This process aligns the iron atoms consistently, enhancing their magnetic properties. Steel strips find wide application in the production of electromagnetic cores, transformers, and inductors. Acting as a magnetic core, the steel strip concentrates and directs the magnetic field, allowing for efficient energy transfer and reduced energy losses in electromagnetic devices. Additionally, steel strips are utilized in magnetic shielding applications. The high magnetic permeability of steel enables it to redirect or absorb magnetic fields, safeguarding sensitive electronic components from electromagnetic interference. In conclusion, the magnetic properties of steel strips play a vital role in various applications. The composition and processing of steel determine its magnetic characteristics, making it a versatile material for electromagnetic cores, transformers, inductors, and magnetic shielding.

Send your message to us

Cold Rolled Steel Strip Stainless Steel Strip Coils

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 100000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords