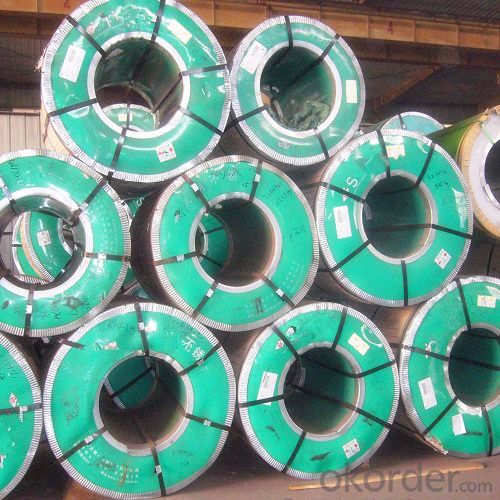

Stainless Steel Coil/Sheet 304 Cold Rolled BA/NO.1

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Chemical composition: | |||||||

C | Si | Mn | Cr | Ni | S | P | |

≤0.07 | ≤1.0 | ≤2.0 | 18.0~20.0 | 8.0~11.0 | ≤0.03 | ≤0.035 | |

mechanical properties: | |||||||

Tensile strength σb (MPa) | Conditions yield strength 0.2 sigma (MPa) | Elongation δ5 (%) | Section shrinkage (%) | Hardness | |||

520 | 205 | 40 | 60 | ≤1 | |||

Standard: | AISI,ASTM,BS,DIN,GB,JIS | Grade: | 304 | Thickness: | 0.3-3.0mm |

Place of Origin: | China Mainland | Brand Name: | CNBM | Model Number: | 304 |

Type: | Steel Coil | Technique: | Cold Rolled | Surface Treatment: | 2B, BA |

Application: | Medical instruments, building, chemical food industry agriculture | Width: | 500-2000mm | Length: | Coil |

finish: | 2B, BA | item: | 304 cold rolled stainless steel coil | density: | 7.93 |

Hot Rolled Stainless Steel Coil 304 Annealing and Pickling No.1 Finish

Stainless steel is a production which not easy rust,acid resistance and corrosion resistance,so it is widely

used in light industry,heavy industry,daily necessities and the decoration industry.

Hot Rolled Stainless Steel Coil 304 Specifications

1.surface:NO.1

2.standard:JIS, AISI, GB

3.width: 0.55m, 0.65m, 1.0m, 1.22m, 1.5m, 2m or requirement

Hot Rolled Stainless Steel Coil 304 Chemical Composition:

(%):C=0.07, Mn=2.00, P=0.045, S=0.030, Si=0.075, Cr=17.5-19.5, Ni=8.0-10.5, N=0.10

Hot Rolled Stainless Steel Coil 304 Physical Properties

Tensile strength σb (MPa) ≥ 520

the conditions yield strength σ0.2 (MPa) ≥ 205,

elongation δ5 (%) ≥ 40

Reduction of ψ (%) ≥ 50,

hardness: ≤ 187

HB; ≤ 90

HRB; ≤ 200H

- Q: Are 111 stainless steel strips suitable for heat sinks?

- 111 stainless steel strips are unsuitable for heat sinks. Heat sinks are designed to effectively dissipate heat from electronic components and thus require materials with high thermal conductivity. Although stainless steel has numerous desirable properties, it lacks good thermal conductivity, particularly when compared to other metals like aluminum or copper that are commonly used for heat sinks. Consequently, it is advisable to utilize materials with higher thermal conductivity for heat sinks in order to guarantee efficient heat dissipation.

- Q: What is the difference between hot rolled and cold rolled stainless steel strips?

- Stainless steel strips undergo different production processes depending on their desired properties. Hot rolled strips are made by passing the steel through rollers at a high temperature, typically above 1,000 degrees Celsius. This increases the steel's malleability, making it easier to shape into various forms. Hot rolled strips generally have a rough surface and slightly rounded edges. In contrast, cold rolled strips are produced by passing the steel through rollers at room temperature or slightly below. This process improves the surface finish and dimensional accuracy of the strips. Cold rolled strips have a smoother surface and sharper edges compared to hot rolled strips. Mechanically, the two types of strips differ as well. Hot rolled strips have a higher yield strength and are more ductile, making them suitable for applications that involve shaping or bending. On the other hand, cold rolled strips have a higher tensile strength and are generally harder, making them ideal for applications that require strength and durability. Cost-wise, hot rolled stainless steel strips are generally cheaper to produce than cold rolled strips. However, the additional processing steps involved in cold rolling often result in higher production costs. Ultimately, the choice between hot rolled and cold rolled stainless steel strips depends on the specific requirements of the application. Hot rolled strips are suitable when shaping or bending is necessary, while cold rolled strips are preferred for their strength and smooth surface finish.

- Q: Are stainless steel strips suitable for HVAC systems?

- Yes, stainless steel strips are suitable for HVAC systems. Stainless steel is a durable and corrosion-resistant material that can withstand high temperatures and harsh environments typically found in HVAC systems. It is also easy to clean and maintain, making it a reliable choice for various applications within the HVAC industry.

- Q: Can stainless steel strips be used in chemical pumps?

- Yes, stainless steel strips can be used in chemical pumps. Stainless steel is highly resistant to corrosion and can withstand a wide range of chemicals, making it a suitable material for use in chemical pumps.

- Q: How do you prevent rust on stainless steel strips?

- To prevent rust on stainless steel strips, it is essential to keep them clean and dry. Regular cleaning with mild soap and water helps remove any dirt or contaminants that may cause corrosion. Additionally, avoiding exposure to harsh chemicals, acids, or chloride-containing compounds can help protect the stainless steel from rusting. Applying a protective coating or using a rust inhibitor can also be effective in preventing rust formation on stainless steel strips.

- Q: Are stainless steel strips resistant to corrosion?

- Stainless steel strips possess corrosion resistance due to their composition. They consist of iron, chromium, and other elements that create a protective layer on the metal's surface. This layer, referred to as a passive film, acts as a barrier between the metal and oxygen and moisture, which are the primary factors behind corrosion. The formation of this protective film is attributed to the chromium content in stainless steel. The higher the chromium content, the greater the corrosion resistance. Consequently, stainless steel strips are renowned for their exceptional ability to withstand corrosion, rendering them suitable for numerous applications across diverse industries.

- Q: Can stainless steel strips be used in the pharmaceutical machinery?

- Yes, stainless steel strips can be used in pharmaceutical machinery. Stainless steel is a commonly used material in the pharmaceutical industry due to its excellent corrosion resistance, durability, and ease of cleaning. It is also non-reactive with most pharmaceutical substances, making it suitable for various applications such as equipment frames, conveyors, tanks, and process piping. Additionally, stainless steel strips can be easily fabricated and customized to meet specific requirements of pharmaceutical machinery, ensuring a high level of quality and reliability in the production processes.

- Q: What is the yield strength of stainless steel strips?

- The yield strength of stainless steel strips is subject to variation based on the particular grade and thickness of the material. Typically, stainless steel strips exhibit superior yield strength in comparison to alternative steel types owing to their composition, which entails a minimum of 10.5% chromium. Nevertheless, the yield strength can span from approximately 200 megapascals (MPa) for subpar stainless steel strips to more than 1000 MPa for top-notch stainless steel strips. It is imperative to refer to the manufacturer's specifications or conduct material testing in order to ascertain the precise yield strength of a given stainless steel strip.

- Q: Are stainless steel strips resistant to chlorine attack?

- Indeed, stainless steel strips exhibit resistance against chlorine attack. Stainless steel is renowned for its exceptional corrosion resistance and can endure exposure to chlorine and other corrosive substances. This resistance stems from the inclusion of chromium in stainless steel, which generates a protective layer on its surface when exposed to oxygen. Consequently, this layer prevents the metal from reacting with chlorine or other corrosive agents. Given their remarkable resistance to chlorine attack, stainless steel strips find widespread usage in numerous industries that involve contact with chlorine. These industries include water treatment plants, swimming pools, and chemical processing facilities.

- Q: Are stainless steel strips suitable for decorative railing systems?

- Yes, stainless steel strips are suitable for decorative railing systems. Stainless steel is known for its durability, corrosion resistance, and aesthetic appeal, making it an excellent choice for decorative applications. Stainless steel strips can be easily fabricated into various shapes and sizes, allowing for intricate and stylish railing designs. Additionally, stainless steel is low-maintenance and can withstand harsh weather conditions, making it ideal for outdoor decorative railing systems.

Send your message to us

Stainless Steel Coil/Sheet 304 Cold Rolled BA/NO.1

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords