1 2 Stainless Steel Tubing

1 2 Stainless Steel Tubing Related Searches

1 2 Inch Stainless Steel Tubing 1 2 Stainless Steel Pipe 2 Stainless Steel Tubing 1 Stainless Steel Tubing 1 1 2 Stainless Steel Pipe 1 Inch Stainless Steel Tubing 1in Stainless Steel Tubing Stainless Steel 1/2 Tubing 1 4 Stainless Steel Tubing 1/2 Stainless Steel Tubing 1 2 Stainless Steel Rod 2 Stainless Steel Pipe 1 Stainless Steel Pipe 2 Inch Stainless Steel Pipe 2 1 2 Cast Iron Pipe 3 4 Stainless Steel Tubing Stainless Steel Tubeing 1 Inch Stainless Steel Pipe Seamless Stainless Steel Tubing Bending Stainless Steel Tubing Stainless Steel Tubs Stainless Steel Coil Tubing 1/4 Stainless Steel Tubing Stainless Steel Tub Stainless Steel Tubes Stainless Steel Piping Square Stainless Steel Tubing Flexible Stainless Steel Tubing 3/4 Stainless Steel Tubing Stainless Steel Tubing Supplier1 2 Stainless Steel Tubing Supplier & Manufacturer from China

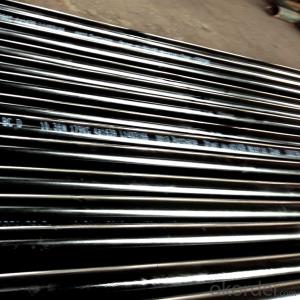

1/2 Stainless Steel Tubing is a versatile product that comes in various grades, such as 304 and 316, and is known for its corrosion resistance, strength, and durability. This type of tubing is widely used in numerous industries, including construction, automotive, and food processing, where it is essential to maintain hygiene and resist harsh environmental conditions. The 1/2 Stainless Steel Tubing is also preferred for its ability to withstand high temperatures and pressures, making it suitable for applications such as fluid transportation and structural support.The 1/2 Stainless Steel Tubing is extensively used in various applications, such as in plumbing systems, gas lines, and industrial equipment. It is also commonly found in architectural designs for its aesthetic appeal and long-lasting properties. The tubing is available in different sizes and wall thicknesses, allowing for customization to meet specific project requirements. Its seamless design ensures a smooth interior surface, which is beneficial for reducing friction and improving fluid flow.

Okorder.com is a reputable wholesale supplier of 1/2 Stainless Steel Tubing, offering a vast inventory to cater to the needs of various industries. As a leading distributor, Okorder.com ensures that the product is of the highest quality and adheres to international standards. Their extensive range of 1/2 Stainless Steel Tubing allows customers to find the exact specifications they require, making it a one-stop solution for all stainless steel tubing needs. With competitive pricing and efficient shipping, Okorder.com is the go-to source for 1/2 Stainless Steel Tubing for both small and large-scale projects.

Hot Products