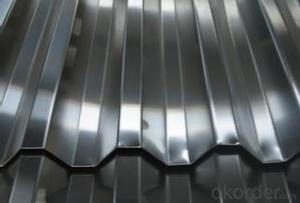

High Quality Stainless Steel Coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 Tons m.t.

- Supply Capability:

- 20000 Ton Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stainless Steel Coil / Sheet

1.Size of Stainless Steel Coil: Thickness: 0.3mm ~~ 6mm, Width: 650mm ~~ 2100mm, Length: to be customized.

2.Material of Stainless Steel Coil:SUS201,202,301,304,304L,316,316L ,321 etc.

3.Standard of Stainless Steel Coil:AISI,JIS,GB,DIN

4.Finish of Stainless Steel Coil:Black, No.1, 2B, 2D, BA, NO.3, NO.4, SB, NO.8, HL

5.Testing of Stainless Steel Coil:Each heat number and batch must be tested for both chemical and mechanical properties

Stainless Steel Coil / Sheet | |

Standard | JIS, AISI, ASTM, GB, DIN, EN |

Property | Stainless steel coil, Stainless steel sheet, Stainless steel plate, stainless steel |

Length | 1-12m |

Quality | prime |

Manufacturing Process | factory direct sale |

Surface Treatment | Black, No.1, 2B, 2D, BA, NO.3, NO.4, SB, NO.8, HL |

Main Grade | 201,201,301,302,303,304,321,316,316L,309,310,309H, 310S,431,430,420,430F |

MOQ | 20 ton |

Trade Term | FOB China mainport |

Payment term | T/T or L/C |

Price | negotiable |

Packing | Export packing |

Dilvery time | 20days or depend on order quantity |

Container | The capacity for a 20" container:20-24tons |

- Q: How do stainless steel strips handle exposure to chlorine?

- Stainless steel strips generally handle exposure to chlorine quite well. Chlorine is not usually corrosive to stainless steel, so the strips can withstand the effects of chlorine exposure without significant damage or degradation.

- Q: Can stainless steel strips be used for heat sinks?

- Indeed, heat sinks can make use of stainless steel strips. Stainless steel possesses commendable thermal conductivity, enabling efficient heat transfer. Moreover, stainless steel exhibits remarkable corrosion resistance, rendering it a robust choice for heat sink purposes. Nevertheless, it is worth mentioning that stainless steel boasts lower thermal conductivity in comparison to widely employed materials such as copper or aluminum, typically employed for heat sinks. Thus, stainless steel strips might prove less efficient than alternative materials in dissipating heat in high-power applications.

- Q: Can stainless steel strips be used in the agricultural industry?

- Yes, stainless steel strips can be used in the agricultural industry. Stainless steel is known for its corrosion resistance, durability, and strength, making it suitable for various agricultural applications. Stainless steel strips can be used to fabricate equipment and components such as tanks, silos, troughs, conveyors, and machinery frames. These strips are resistant to rust and can withstand harsh environmental conditions, including exposure to moisture, chemicals, and agricultural substances. Moreover, stainless steel is easy to clean and maintain, making it a hygienic choice for applications in the agricultural industry. Overall, stainless steel strips offer numerous benefits and can be effectively utilized in various agricultural processes and equipment.

- Q: What are the different types of finishes available for stainless steel strips?

- Stainless steel strips come in various finishes, each with its own unique characteristics and aesthetic appeal. Here are some of the most common finishes: 1. The No.1 Finish, also known as hot-rolled annealed and pickled (HRAP), is the most basic and rough finish. It has a matte appearance with visible grain lines and is commonly used in industrial applications. 2. The No.2B Finish is achieved by cold rolling the stainless steel strip after pickling and annealing. It has a smooth, reflective surface with a moderately shiny appearance. This finish is widely used in architectural, kitchen, and equipment applications. 3. The No.2D Finish is similar to No.2B but achieved by further cold rolling the strip to achieve a smoother finish. It has a slightly duller appearance than No.2B and is commonly used for deep-drawn applications. 4. The No.3 Finish, also known as a ground finish, is achieved by polishing the stainless steel strip using abrasives. It has a semi-reflective appearance with a uniform grain pattern and is often used for architectural and decorative applications. 5. The No.4 Finish is a popular choice as it combines a polished appearance with excellent corrosion resistance. It is achieved by further polishing the strip after No.3 finish, resulting in a smooth, brushed appearance. 6. The No.6 Finish is achieved by polishing the stainless steel strip using finer abrasives, resulting in a higher level of reflectivity and a mirror-like appearance. It is commonly used for decorative and architectural applications. 7. The No.7 Finish is similar to No.6 but with an even higher level of reflectivity. It is achieved by using even finer abrasives during the polishing process. No.7 finish is often used for decorative purposes or in high-end architectural projects. 8. The No.8 Finish, also known as a mirror finish, is the highest level of reflectivity available for stainless steel strips. It is achieved by using extremely fine abrasives during the polishing process. No.8 finish is commonly used for decorative applications, such as in furniture and automotive trim. These are just a few examples of the many finishes available for stainless steel strips. The choice of finish depends on the desired appearance, functionality, and application requirements.

- Q: Can stainless steel strips be used in defense applications?

- Indeed, defense applications can make use of stainless steel strips. Renowned for its strength, durability, and resistance to corrosion, stainless steel proves to be an ideal material for various defense-related purposes. Its exceptional qualities enable the manufacturing of military vehicle components, including armor plating, brackets, and reinforcements, as it can endure high impact and provide protection against ballistic threats. In addition, stainless steel strips find utility in fabricating weapon systems, ammunition, and equipment employed by defense forces. The material's ability to resist heat and corrosion renders it suitable for applications such as missile casings and jet engine components. Consequently, stainless steel strips are extensively employed in defense applications due to their superior mechanical properties and reliability.

- Q: How wide are stainless steel strips typically available?

- A variety of widths are typically offered for stainless steel strips, ranging from as narrow as 0.25 inches (6.35 mm) to as wide as 24 inches (609.6 mm) or even wider. The supplier or manufacturer and the intended application of the stainless steel strips may influence the specific width options. Nevertheless, it is crucial to acknowledge that these width ranges are commonly available, and stainless steel strips can be tailored to meet specific width requirements if necessary.

- Q: What are the common uses of stainless steel strips in the food manufacturing process?

- Stainless steel strips are commonly used in the food manufacturing process for applications such as conveyor belts, food processing equipment, food storage containers, and packaging materials. Their corrosion resistance, hygienic properties, and ability to withstand high temperatures make them ideal for ensuring food safety and maintaining cleanliness in food processing environments.

- Q: Can stainless steel strips be machined?

- Yes, stainless steel strips can be machined. Machining stainless steel strips involves various processes such as cutting, drilling, milling, and turning. However, it is important to note that stainless steel is a hard material, so machining it requires the use of appropriate tools and techniques. Additionally, the specific type of stainless steel and its properties will also determine the ease and effectiveness of the machining process.

- Q: Are stainless steel strips suitable for architectural signage?

- Architectural signage can benefit greatly from the use of stainless steel strips. This material is a popular choice due to its durability, aesthetic appeal, and resistance to corrosion. With its versatility, stainless steel can be easily shaped into different sizes and forms to create various types of signage, including letters, logos, and plaques. When it comes to appearance, stainless steel strips offer a sleek and modern look that can complement any architectural design. They can be finished in different ways, such as brushed, polished, or etched, to achieve the desired visual effect. Not only do they look good, but they also provide excellent weather resistance, making them suitable for both indoor and outdoor signage. Apart from its visual qualities, stainless steel is highly durable and can withstand harsh environmental conditions. It is resistant to corrosion, rust, and fading, ensuring that the signage remains visually appealing and readable for a long time. This makes stainless steel strips a reliable choice for architectural signage, especially in areas with high levels of foot traffic or exposure to extreme weather. Another advantage of using stainless steel is its low maintenance requirements. It is easy to clean and maintain, making it a cost-effective choice in the long run. In summary, stainless steel strips are a suitable option for architectural signage due to their durability, aesthetic appeal, resistance to corrosion, and low maintenance requirements. Whether it's for commercial buildings, residential complexes, or public spaces, stainless steel signage can add a touch of sophistication and professionalism to any architectural project.

- Q: Can stainless steel strips be used in telecommunications equipment?

- Indeed, in telecommunications equipment, stainless steel strips find utility. Frequently, stainless steel is opted for due to its robustness, resistance to corrosion, and strength. These attributes render stainless steel strips apt for an array of applications in telecommunications equipment, including cable support brackets, antenna mounts, enclosures, and cable trays. The resistance of stainless steel to rust and corrosion guarantees unwavering reliability and functioning of the equipment, even in the face of severe environmental conditions. Furthermore, the strength of stainless steel empowers it to endure the weight and strain of hefty equipment and cables, thereby establishing it as the favored choice in the telecommunications industry.

1. Manufacturer Overview

| Location | Zhejiang,China |

| Year Established | 2010 |

| Annual Output Value | Above US$16Million |

| Main Markets | Japan, South America |

| Company Certifications | ISO9001:2000; |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 60% |

| No.of Employees in Trade Department | 50 People |

| Language Spoken: | English;Chinese; Japanese |

| b) Factory Information | |

| Factory Size: | Above 80,000 square meters |

| No. of Production Lines | Above 8 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

High Quality Stainless Steel Coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 Tons m.t.

- Supply Capability:

- 20000 Ton Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords