Stainless Steel Coil Cold Rolled AISI 304 With Good Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stainless Steel Coil Cold Rolled 304 With Good Quality

1.Structure of Stainless Steel Coil Cold Rolled 304 With Good Quality

Cold Rolled stainless steel Coil with good quality is one of the raw material of the cold rolled stainless steel Coil, which can be used directly in many places. Stainless Steel (Stainless Steel) is short for acid-proof Stainless Steel, resistant to weak corrosive medium such as air, steam, water, or with a Stainless Steel grade.

2.Main Features of Prefabricated Steel Structure High Building Project

1) Weldability: The purpose of the different requirement for welding performance are different.1 Kind of tableware generally do not require the performance of welding, even including some pot class enterprise. But the vast majority of products all need raw materials welding performance is good, like the 2 kinds of tableware, thermos flask, steel pipes, water heaters, water dispensers, etc.

2) Corrosion resistance The vast majority of stainless steel products for corrosion resistant performance is good, like a, 2 kinds of tableware, kitchen utensils and appliances, water heaters, water dispensers, etc., some foreign businessmen on corrosion resistance of products also do experiment: in NACL aqueous solution heated to boiling, after a period of time the best solution, wash and drying, weight loss, to determine the degree of corrosion (note: the product polishing, because of the sand cloth or sandpaper containing Fe, will cause the test surface rust spots)

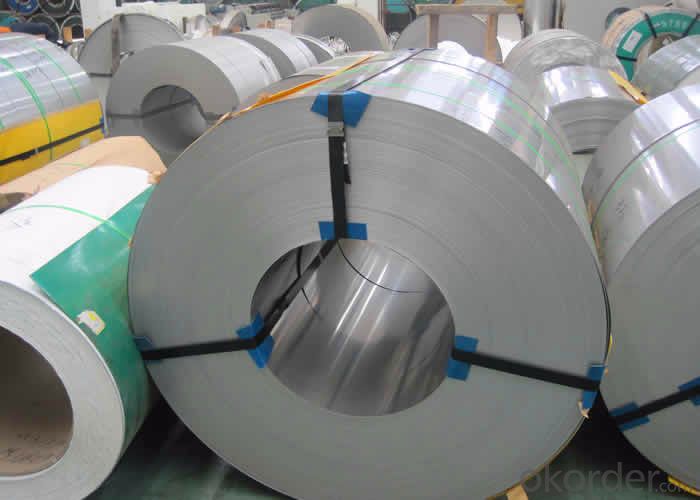

3. Stainless Steel Coil Cold Rolled 304 With Good Quality Images

4. Stainless Steel Coil Cold Rolled 304 With Good Quality Specification

The word "stainless steel" is not merely refers to a pure stainless steel, but said more than one hundred kinds of stainless steel industry, the development of each stainless steel has good performance in their specific applications. The key to the success of the first is to make clear purpose, and then determine the correct material. Related to architectural construction applications usually only six types of steel. They contain 17 ~ 22% chromium, good steel contains nickel. Add molybdenum can further improve the atmospheric corrosion resistance, especially containing chloride atmospheric corrosion resistance. Stainless steel often according to the state of organization can be divided into: martensite steel, ferritic steel, austenitic steel, austenitic (two-phase) - ferrite stainless steel and precipitation hardening stainless steel, etc. In addition, according to ingredients can be divided into: chromium stainless steel, chromium nickel stainless steel and chromium manganese nitrogen stainless steel, etc.

5. Applications of Stainless Steel Coil 304 With Good Quality

1. Kitchenware: tableware, cookware, Stoves…

2. Food packing: storage cans, food containers…

3. Construction: bridge, roofing, wall, decoration, bathroom accessories…

4. Precision instruments: electrical products, aerospace…

5. Others: automotive parts, machine building, chemical processing, farming…

6.FAQ of Stainless Steel Coil 304 With Good Quality

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How is the packaging and delivery?

Standard export packing (Coil: waterproof paper + protective steel ring; Circle: wooden box), or as your requirement and the delivery term is based on the project.

④How long can we receive the product after purchase?

In the purchase of product within 20 working days, We will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 20 to 40 working days can be served.

- Q: Can stainless steel strips be used in the semiconductor industry?

- Yes, stainless steel strips can be used in the semiconductor industry. Stainless steel is known for its excellent corrosion resistance, high strength, and durability, making it a suitable material for various applications in the semiconductor industry. Stainless steel strips are often used in the fabrication of semiconductor equipment, such as chambers, wafer carriers, and process tools, where they can withstand harsh environments and high temperatures. Additionally, stainless steel strips can be precision-engineered to meet specific requirements, ensuring dimensional accuracy and reliability in semiconductor manufacturing processes.

- Q: Can stainless steel strips be used in solar panels?

- Yes, stainless steel strips can be used in solar panels. Stainless steel is a durable and corrosion-resistant material, making it suitable for use as a component in solar panels. It can be used as a support structure or as part of the wiring and connectors within the panels.

- Q: What are the applications of stainless steel strips?

- Due to their outstanding properties, stainless steel strips find wide-ranging applications across various industries. They are commonly used in construction and architecture for structural components, roofing, cladding, and facades. Their exceptional durability, corrosion resistance, and aesthetic appeal make them an ideal choice in architectural projects. In the automotive industry, stainless steel strips are utilized for manufacturing exhaust systems, trim components, and decorative parts. Their high strength, heat resistance, and corrosion resistance make them suitable for these purposes. Stainless steel strips are extensively employed in the production of kitchen appliances such as refrigerators, ovens, dishwashers, and sinks. Their hygienic properties, resistance to stains and corrosion, and ease of cleaning make them a popular choice in the kitchen. In the medical field, stainless steel strips are used for manufacturing surgical instruments, implants, and medical devices. Their biocompatibility, resistance to sterilization processes, and corrosion resistance make them suitable for use in healthcare settings. The petrochemical industry relies on stainless steel strips for manufacturing equipment like storage tanks, pipelines, and valves. The corrosion resistance of stainless steel strips is crucial in ensuring the safety and reliability of these critical components. The electronics and electrical industry also utilizes stainless steel strips in electronic devices, electrical contacts, connectors, and circuits. This is due to their electrical conductivity and corrosion resistance, which provide excellent shielding against electromagnetic interference and ensure long-term reliability. In the food processing industry, stainless steel strips are widely used for manufacturing equipment such as conveyors, mixers, tanks, and processing machinery. Their corrosion resistance, easy cleaning, and hygienic properties make them suitable for handling food products. In the aerospace industry, stainless steel strips are employed for manufacturing aircraft components like turbine blades, exhaust systems, and structural parts. Their high strength-to-weight ratio, resistance to extreme temperatures, and corrosion resistance are critical in aerospace applications. These examples highlight the versatility, durability, and corrosion resistance of stainless steel strips, making them the preferred choice in various industries where strength, reliability, and aesthetics are essential.

- Q: Why does stainless steel carry magnetism?

- In fact, there is also a stainless steel magnet can not afford, that is, high manganese or nitrogen and low nickel or nickel free stainless steel, chromium, manganese austenitic stainless steel, so it can not be based on whether or not to determine whether the magnetic stainless steel

- Q: Can stainless steel strips be used in chemical processing plants?

- Chemical processing plants can utilize stainless steel strips. Stainless steel possesses exceptional resistance to corrosion, rendering it extremely appropriate for use in chemical-rich settings. These strips withstand both organic and inorganic chemicals, encompassing acids, alkalis, and salts. Moreover, stainless steel is easily cleaned and maintained, thus being a favored option in hygienic-minded chemical processing plant applications. These strips are also capable of enduring high temperatures, qualifying them for employment in numerous processes like distillation, evaporation, and filtration. In sum, stainless steel strips prove themselves as reliable and long-lasting selections for chemical processing plants due to their corrosion resistance, low maintenance requirements, and capacity to endure harsh surroundings.

- Q: How do you measure the thickness of stainless steel strips?

- Depending on the level of accuracy and precision needed, there are several methods available for measuring the thickness of stainless steel strips. Here are a few commonly employed techniques: 1. Utilizing calipers: For a straightforward and easily accessible approach, calipers are an ideal tool. To measure the thickness, employ a digital or vernier caliper with fine jaws to determine the distance between the strip's opposing surfaces. For accurate readings, it is crucial to ensure that the caliper is perpendicular to the strip. 2. Implementing a micrometer: When a higher level of precision is required, a micrometer is the instrument of choice. Comprised of a calibrated screw mechanism and anvil, the micrometer should be used by placing the strip between the anvil and the spindle and tightening the screw until it is snug. The thickness can then be read on the micrometer barrel. 3. Employing an ultrasonic thickness gauge: This method, which does not cause any damage to the material being measured, employs sound waves to determine thickness. By sending high-frequency sound pulses through the strip and calculating the time it takes for the echo to return, the thickness can be accurately determined. Ultrasonic thickness gauges are particularly suitable for measuring thicker strips. 4. Utilizing an optical profilometer: This advanced technique involves the use of a laser or light source to analyze variations in height on the surface of the strip. By scanning the strip with an optical profiler, the thickness can be accurately measured by calculating the differences in height. It is important to consider the range of thickness, accuracy requirements, and availability of equipment when selecting a measurement method. In cases where precision is of utmost importance, it is advisable to either use a combination of methods or seek the assistance of a professional to ensure accurate measurements.

- Q: Can stainless steel strips be used in the production of electrical connectors?

- Yes, stainless steel strips can be used in the production of electrical connectors. Stainless steel is a highly versatile material that offers excellent mechanical properties, such as high strength, durability, and corrosion resistance. These qualities make it suitable for various applications, including electrical connectors. Stainless steel strips can be fabricated into precise shapes and sizes, allowing for the production of connectors with tight tolerances. Additionally, stainless steel's resistance to oxidation and corrosion ensures the longevity and reliability of the connectors, even in harsh environments. Overall, stainless steel strips are a viable material choice for the production of electrical connectors.

- Q: Can stainless steel strips be used for food storage containers?

- Yes, stainless steel strips can be used for food storage containers. Stainless steel is a popular choice for food storage containers due to its durability, resistance to corrosion, and its ability to prevent the transfer of odors and flavors. It is a safe and hygienic material that does not react with acidic or alkaline foods, making it suitable for storing a wide range of food items.

- Q: How do stainless steel strips handle exposure to saltwater?

- Stainless steel strips are highly resistant to corrosion and can handle exposure to saltwater exceptionally well. The chromium content in stainless steel forms a protective oxide layer on the surface, preventing the metal from reacting with the saltwater. This makes stainless steel strips highly durable and suitable for various applications in marine environments.

- Q: How do stainless steel strips resist scaling?

- Stainless steel strips resist scaling primarily due to the presence of chromium in their composition. The chromium content in stainless steel forms a passive oxide layer on the surface, known as chromium oxide. This thin layer acts as a protective barrier against oxidation, preventing the metal from further reacting with oxygen in the environment and thus resisting scaling. Additionally, the presence of other alloying elements such as nickel and molybdenum further enhances the corrosion resistance and scaling resistance properties of stainless steel strips. The combination of these elements creates a stable and durable oxide layer, making stainless steel highly resistant to scaling even at high temperatures.

Send your message to us

Stainless Steel Coil Cold Rolled AISI 304 With Good Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords