309S Stainless Steel Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Ton m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

309S stainless steel sheet

1. Chemical composition

|

C |

Si |

Mn |

P |

S |

Ni |

Cr |

|

0.08 |

max1.00 |

Max2.00 |

max0.045 |

max0.03 |

12.0-15.0 |

22.0.00-24.00 |

2. Mechanical properties

|

Yield Strength |

Tensile |

Elongation |

Hardness (HV) |

Hardness (HRB) |

|

≥205 |

≥520 |

≥ 40 |

≥200 |

≥90 |

3. Standard: AISI, ASTM, GB, EN, DIN, JIS

4. Surface: 2B, NO.1, BA, NO.4, Hairline, SB, Mirror finish, Anti-skid, Cherkered etc.

5. Size: Thickness: 0.3-3mm (cold rolled), 3-40mm (hot rolled)

Width: 1000mm or 1219mm or 1240mm for cold rolled, 1500mm for hot rolled.

Length: As customers' request.

6. MOQ: 1 Ton

7. Payment terms: T/T or L/C

8. Packing: Seaworthy package with wooden or Iron pallets with the paper and the steel strip, or as customers' request.

9. Delivery time: Usually about 7 days after we confirming the order, or according to your quantity.

If you have any question or demand, pls feel free to contact me.

- Q: What are the different types of edge finishes for stainless steel strips?

- Some common types of edge finishes for stainless steel strips include mill edge, slit edge, deburred edge, rounded edge, and beveled edge.

- Q: Can stainless steel strips be used in the pharmaceutical equipment industry?

- Stainless steel strips are indeed applicable in the pharmaceutical equipment industry. Due to its exceptional resistance to corrosion, remarkable strength, and hygienic characteristics, stainless steel is widely favored in this sector. Numerous elements of pharmaceutical equipment, such as storage tanks, mixing vessels, piping systems, and conveyors, are frequently fabricated using stainless steel strips. The smooth and easily cleaned surface of stainless steel is perfect for upholding stringent cleanliness standards and preventing contamination during pharmaceutical manufacturing procedures. Moreover, stainless steel is highly enduring and capable of withstanding the harsh conditions commonly encountered in pharmaceutical manufacturing facilities. Consequently, stainless steel strips represent a dependable and appropriate material for utilization in the pharmaceutical equipment industry.

- Q: Can stainless steel strips be used in high-temperature environments?

- Yes, stainless steel strips can be used in high-temperature environments. Stainless steel is known for its excellent heat resistance and can withstand high temperatures without losing its strength or becoming susceptible to corrosion. This makes it a suitable choice for applications that require durability and stability in extreme heat conditions.

- Q: What are the different finishes available for stainless steel strips?

- Stainless steel strips come in a variety of finishes, each with its own unique characteristics and visual appeal. Let's explore the different options available: 1. No. 1 Finish: This finish is achieved by hot-rolling and then annealing and descaling the stainless steel strip. It results in a rough and matte surface, making it suitable for industrial applications where appearance is not a top priority. 2. No. 2D Finish: Also known as a "dull" finish, this option involves cold-rolling the stainless steel strip after annealing. The result is a smoother and more reflective appearance compared to the No. 1 finish. 3. No. 2B Finish: This bright and cold-rolled finish is commonly used in commercial and residential settings. It boasts a smooth and reflective surface, making it ideal for decorative purposes. 4. No. 3 Finish: Achieved by using a 120-150 grit abrasive, this finish provides a more uniform and polished appearance compared to the previous options. 5. No. 4 Finish: Among the most popular choices, this finish is achieved by using a 150-180 grit abrasive. It creates a brushed or satin-like appearance and is often used in architectural and decorative applications. 6. No. 6 Finish: This finish involves using a 240 grit abrasive, resulting in a finer brushed appearance compared to the No. 4 finish. It is commonly used in high-end architectural and decorative projects. 7. No. 7 Finish: For a highly reflective mirror-like finish, this option employs a 320 grit abrasive. It lends a polished and sleek appearance, making it perfect for decorative applications. 8. No. 8 Finish: This is the highest grade mirror-like finish available for stainless steel strips. It is achieved by using a 400-600 grit abrasive, resulting in a flawless and reflective surface. It is commonly used in high-end architectural, automotive, and decorative projects. These different finishes offer versatility in design and functionality, catering to various industries and aesthetic preferences.

- Q: What are the different types of embossing for stainless steel strips?

- There are several types of embossing techniques used for stainless steel strips, including diamond, quilted, linen, leather, and hammered patterns. These techniques create different textures and patterns on the surface of the stainless steel strips, providing aesthetic appeal and enhancing their functionality in various applications.

- Q: Are stainless steel strips suitable for brewery tanks?

- Yes, stainless steel strips are suitable for brewery tanks. Stainless steel is corrosion-resistant, easy to clean, and provides a hygienic surface for storing and fermenting beer. It also maintains the quality and flavor of the beer, making it the preferred material for brewery tanks.

- Q: How do stainless steel strips handle exposure to chemicals?

- Stainless steel strips are highly resistant to the effects of exposure to chemicals. This is due to the inherent properties of stainless steel, which include high corrosion resistance and the ability to withstand a wide range of chemical substances. Stainless steel contains a minimum of 10.5% chromium, which forms a passive, self-repairing oxide layer on the surface when exposed to oxygen. This oxide layer acts as a protective barrier, preventing the steel from reacting with chemicals and thus preserving its integrity. Additionally, stainless steel contains other elements such as nickel and molybdenum, which further enhance its resistance to chemical attack. As a result, stainless steel strips are widely used in industries where they come into contact with various chemicals, such as pharmaceuticals, food processing, and chemical manufacturing. They can withstand exposure to acids, alkalis, solvents, and other corrosive substances, maintaining their strength and durability over time. However, it is important to note that the exact resistance of stainless steel to specific chemicals may vary, and it is advisable to consult the manufacturer or refer to corrosion resistance charts for more detailed information on the compatibility of stainless steel with specific chemicals.

- Q: Can stainless steel strips be used in the aerospace engine components?

- Yes, stainless steel strips can be used in aerospace engine components. Stainless steel offers excellent strength, durability, and resistance to high temperatures, making it suitable for various engine parts such as turbine blades, combustion chambers, and exhaust systems. Additionally, stainless steel's corrosion resistance properties are vital in the aerospace industry, ensuring longevity and reliability in harsh operating conditions.

- Q: What are the common uses of stainless steel strips in the aerospace industry?

- Stainless steel strips are commonly used in the aerospace industry for a variety of applications. They are utilized in the production of aircraft components such as fuel lines, exhaust systems, fasteners, and structural parts. The resistance to corrosion and high temperature properties of stainless steel make it an ideal material choice for these critical aerospace applications.

- Q: Can stainless steel strips be used in the production of aerospace components?

- Yes, stainless steel strips can be used in the production of aerospace components. Stainless steel is widely used in the aerospace industry due to its excellent properties such as high strength, corrosion resistance, and heat resistance. These properties make stainless steel strips suitable for various aerospace applications, including the manufacturing of structural components, fasteners, and fittings. Additionally, stainless steel's ability to withstand extreme temperatures and exposure to harsh environments makes it a reliable material for aerospace components.

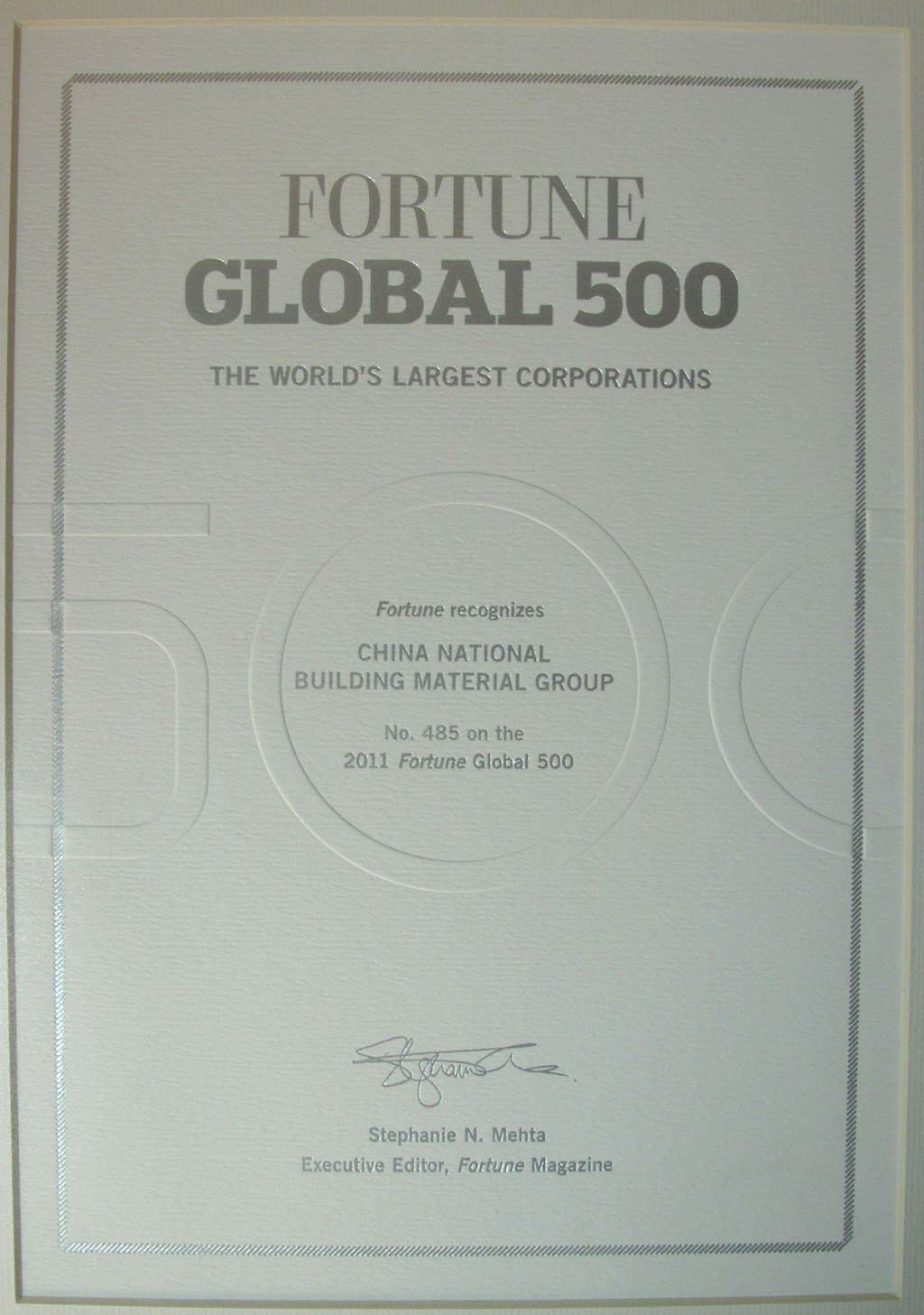

1. Manufacturer Overview

| Location | Wuxi,China |

| Year Established | 2000 |

| Annual Output Value | Above US$16 Million |

| Main Markets | Chinese, Europe,South Africa |

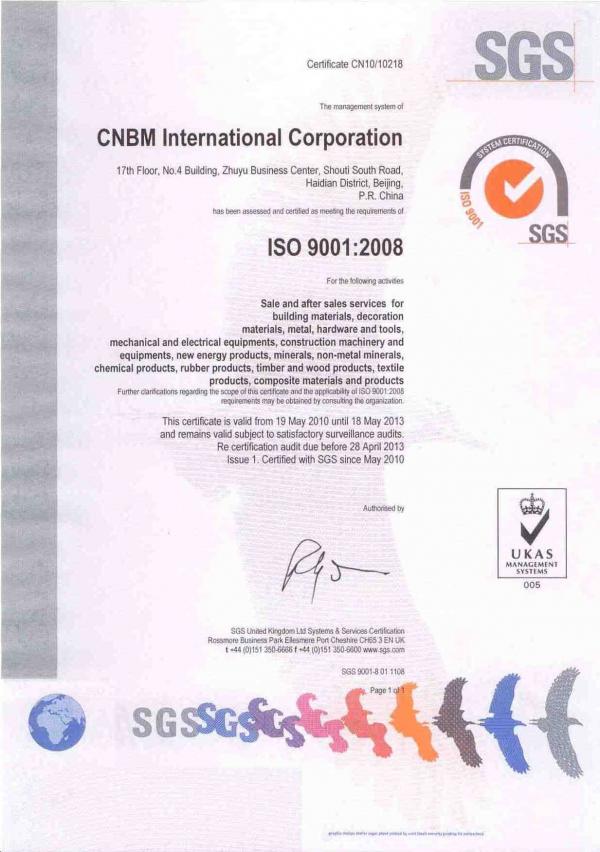

| Company Certifications | ISO9001:2000; |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 30% |

| No.of Employees in Trade Department | 50 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 80,000 square meters |

| No. of Production Lines | Above 7 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

309S Stainless Steel Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Ton m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords