430 Stainless Steel Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Ton m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

430 Stainless steel sheet

1. Chemical composition

|

C |

Si |

Mn |

P |

S |

Ni |

Cr |

|

max0.12 |

max1.00 |

max1.00 |

max0.04 |

max0.03 |

--- |

16.00-18.00 |

2. Mechanical properties

|

Yield Strength |

Tensile |

Elongation |

Hardness (HV) |

Hardness (HRB) |

|

≥205 |

≥420 |

≥22 |

≤200 |

≤88 |

3. Standard: AISI, ASTM, GB, EN, DIN, JIS

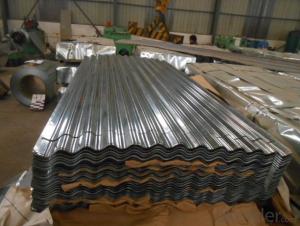

4. Surface: 2B, NO.1, BA, NO.4, Hairline, SB, Mirror finish, Anti-skid, Cherkered etc.

5. Size: Thickness: 0.3-3mm (cold rolled), 3-40mm (hot rolled)

Width: 1000mm or 1219mm or 1240mm for cold rolled, 1500mm for hot rolled.

Length: As customers' request.

6. MOQ: 1 Ton

7. Payment terms: T/T or L/C

8. Packing: Seaworthy package with wooden or Iron pallets with the paper and the steel strip, or as customers' request.

9. Delivery time: Usually about 7 days after we confirming the order, or according to your quantity.

If you have any question or demand, pls feel free to contact me.

- Q: Can stainless steel strips be used in chemical pumps?

- Indeed, chemical pumps can employ stainless steel strips for their operation. Stainless steel boasts remarkable resistance against corrosion and can endure exposure to a diverse array of chemicals. It finds widespread application in the fabrication of chemical pumps and other apparatuses that encounter corrosive substances. By utilizing stainless steel strips, the pump's robustness and longevity are secured, rendering it apt for handling a multitude of chemical variants.

- Q: Can stainless steel strips be used in heat-resistant furnaces?

- Yes, stainless steel strips can be used in heat-resistant furnaces. Stainless steel is known for its high temperature resistance, making it suitable for use in furnaces that require heat-resistant materials. It has excellent oxidation resistance, which enables it to withstand high temperatures without corroding or deforming. Additionally, stainless steel has good thermal conductivity, allowing it to distribute heat evenly throughout the furnace. Its durability and strength also make it a reliable choice for withstanding the harsh conditions inside a heat-resistant furnace. Overall, stainless steel strips are a suitable material for use in heat-resistant furnaces due to their high temperature resistance, corrosion resistance, thermal conductivity, and durability.

- Q: Can stainless steel strips be used in nuclear power applications?

- Yes, stainless steel strips can be used in nuclear power applications. Stainless steel is a preferred material in the nuclear industry due to its excellent resistance to corrosion, high-temperature strength, and low magnetic permeability. It is commonly used for a range of applications including reactor components, fuel storage containers, heat exchangers, and piping systems. Stainless steel strips offer the advantage of being easily formed into various shapes and sizes, making them suitable for different nuclear power applications. Additionally, stainless steel's ability to withstand radiation damage and its minimal interaction with nuclear fuel further contribute to its suitability in nuclear power applications.

- Q: Can stainless steel strips be used in automotive body panels?

- Indeed, automotive body panels can utilize stainless steel strips. With its versatility and durability, stainless steel proves to be an exceptional material that offers remarkable resistance against corrosion, substantial strength, and an elegant appearance. Due to these properties, stainless steel is suitable for various automotive applications, including body panels. These strips can be manipulated, welded, and molded into diverse panel designs, granting flexibility and customization options in terms of design. Moreover, stainless steel's ability to withstand rust and oxidation renders it ideal for enduring harsh outdoor conditions and exposure to road salt, which are prevalent in automotive environments. In summary, stainless steel strips present a dependable and long-lasting solution for automotive body panels.

- Q: Can stainless steel strips be used for kitchen appliances?

- Yes, stainless steel strips can be used for kitchen appliances. Stainless steel is a popular choice for kitchen appliances due to its durability, corrosion resistance, and sleek appearance. It provides a hygienic surface that is easy to clean and maintain. Stainless steel strips can be used to cover and protect various parts of kitchen appliances such as refrigerator doors, dishwasher panels, oven fronts, and range hoods. Additionally, stainless steel strips can be customized in terms of thickness, width, and finish to meet specific design requirements. Overall, stainless steel strips are a versatile and practical option for enhancing the aesthetics and functionality of kitchen appliances.

- Q: How are stainless steel strips made?

- Stainless steel strips are manufactured through a process known as cold rolling. This involves passing a stainless steel coil through a set of rollers at room temperature, which gradually reduces the thickness and increases the length of the coil. Initially, the stainless steel coil is unwound and cleaned to remove any dirt or impurities. It then goes through a series of rolling mills, where the thickness is progressively reduced. Each mill consists of two or more rollers that exert pressure on the metal, causing it to elongate and become thinner. The process is repeated several times until the desired thickness is achieved. As the stainless steel strip gets thinner, it becomes more rigid and difficult to manipulate. To counteract this, annealing is performed at specific intervals during the rolling process. Annealing involves heating the strip to high temperatures and then allowing it to cool slowly. This helps to relieve internal stresses and improve the strip's ductility. After the cold rolling and annealing stages, the stainless steel strip may undergo additional processes, such as descaling, pickling, and passivating. Descaling removes any scales or oxides that may have formed on the strip's surface during rolling. Pickling involves treating the strip with an acid solution to remove any remaining impurities. Passivation is a final step that enhances the stainless steel's corrosion resistance by forming a thin, protective oxide layer on its surface. Once all these processes are complete, the stainless steel strip is cut to the desired length and packaged for shipment or further processing. It can be used in a wide range of applications, such as automotive components, kitchen appliances, construction materials, and electronic devices, due to its excellent strength, durability, and resistance to corrosion.

- Q: Are stainless steel strips resistant to magnetism?

- Yes, stainless steel strips are generally resistant to magnetism.

- Q: Are stainless steel strips suitable for chemical tanks?

- Yes, stainless steel strips are suitable for chemical tanks. Stainless steel is highly resistant to corrosion and can withstand a wide range of chemicals, making it a suitable material for storing and transporting various chemical substances.

- Q: How do stainless steel strips perform in high temperature environments?

- Stainless steel strips perform exceptionally well in high temperature environments due to their excellent heat resistance properties. They maintain their strength and structural integrity, without deformation or warping, even under extreme heat conditions. This makes stainless steel strips a reliable choice for various applications in industries like aerospace, power generation, and automotive, where high temperatures are prevalent.

- Q: Are 111 stainless steel strips suitable for heat recovery systems?

- 111 stainless steel strips are not typically suitable for heat recovery systems. Heat recovery systems require materials that can withstand high temperatures and have good heat transfer properties. While stainless steel is known for its corrosion resistance, it may not have the necessary thermal conductivity or tolerance for high temperatures that are crucial for heat recovery systems. It is advisable to consult with a professional engineer or specialist in heat recovery systems to determine the most suitable materials for your specific application.

1. Manufacturer Overview

| Location | Guangzhou,China |

| Year Established | 2001 |

| Annual Output Value | Above US$0.5 Million |

| Main Markets | Southeast Asia, Europe |

| Company Certifications | ISO 9001:2008; |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 30% |

| No.of Employees in Trade Department | 10 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 30,000 square meters |

| No. of Production Lines | Above 7 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

430 Stainless Steel Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Ton m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords