Stainless Steel 4x8 Sheet

Stainless Steel 4x8 Sheet Related Searches

4x8 Stainless Steel Sheet Stainless Steel 4x8 Sheets Stainless Steel Sheets 4x8 4x8 Sheet Of Stainless Steel 4 X 8 Sheet Of Stainless Steel 4x8 Stainless Steel Sheet Price Galvanized Steel Sheet 4x8 1 8 Stainless Steel Sheet 4X8 Metal Sheets 4X8 Sheet Aluminum 1/8 Stainless Steel Sheet 4X8 Styrofoam Sheets Sheet Metal Sheets 4X8 Sheet Metal 4X8 4X8 Galvanized Sheet Metal Plastic Sheets 4X8 Aluminum Tread Plate Sheet 4x8 Hard Plastic Sheets 4X8 Galvanized Sheet Metal 4X8 4X8 Tin Sheets Polypropylene Sheets 4X8 Aluminum Diamond Plate 4x8 Sheet Plexiglass Sheets 4X8 Clear Plastic Sheets 4X8 4 X 8 Styrofoam Sheets Diamond Plate Aluminum Sheets 4X8 Sheet Of Stainless Steel 4x8 Sheet Aluminum Diamond Plate 4x8 Sheet Diamond Plate Aluminum 22 Gauge Sheet Metal 4X8Stainless Steel 4x8 Sheet Supplier & Manufacturer from China

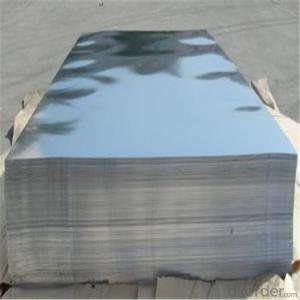

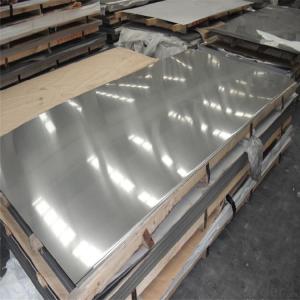

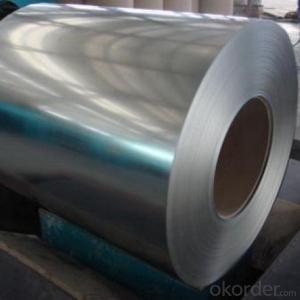

Stainless Steel 4x8 Sheets are versatile metal products known for their corrosion resistance, durability, and aesthetic appeal. These sheets are made from stainless steel alloys, which are widely recognized for their strength and resistance to various environmental factors. They are available in various grades, such as 304, 316, and 430, each with its own specific properties and applications.The Stainless Steel 4x8 Sheets are commonly used in a multitude of industries and applications, including construction, automotive, food processing, and home appliances. They are ideal for creating countertops, backsplashes, sinks, and other surfaces that require a hygienic and easy-to-clean material. Additionally, their resistance to corrosion makes them suitable for outdoor applications and environments where exposure to moisture and chemicals is common.

Okorder.com is a leading wholesale supplier of Stainless Steel 4x8 Sheets, offering a vast inventory of high-quality products to cater to the diverse needs of customers. With a commitment to providing exceptional service and competitive pricing, Okorder.com ensures that customers can find the perfect Stainless Steel 4x8 Sheets for their specific requirements.

Hot Products