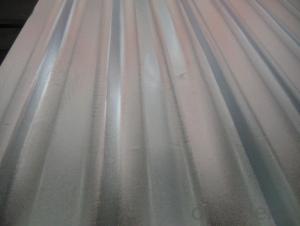

Galvalume Corrugated Steel Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

We specialize in manufacturing galvanized steel coil, galvalume steel coil, prepainted steel coil and galvanized corrugated sheets.

Nowadays our company has grown up to a collectivized company . We are grateful to the cooperation partner who`s grown with us all the way. We hope we could make more friends from all over the world. Under the joint efforts of both sides we believe that we will continue to achieve win-win results based on mutual trust and mutual support.

Quick Details

| Standard: | Grade: | Thickness: | |||

| Place of Origin: | Brand Name: | Model Number: | |||

| Type: | Technique: | Surface Treatment: | |||

| Application: | Special Use: | Width: | |||

| Length: | Based Material: | Material: | |||

| Zinc Coated: | Spangle: | Shape: | |||

| Galvanized Type: | Business: | Payment Terms: | |||

| Packaging: | Delivery Detail: |

Packaging & Delivery

| Packaging Detail: | Fully seaworthy export packing with paper tube Each coil is wrapped in water-proof paper. |

| Delivery Detail: | about 15 days after the deposit if the quantity below 500 ton. |

Specifications

Corrugated gi/gl/ppgi Sheet

1.Thickness: 0.13mm-1.0mm

2.Width:750mm-1250mm

3. z40-z150g/m2

4.ISO 2000,SGS

- Q: What are the main applications of steel sheets?

- Steel sheets have a wide range of applications in various industries due to their durability, strength, and versatility. Some of the main applications of steel sheets include: 1. Construction: Steel sheets are widely used in the construction industry for making beams, columns, and structural frames. They provide strength and stability to buildings, bridges, and other infrastructure projects. 2. Automotive industry: Steel sheets are extensively used in the automotive industry for manufacturing vehicle bodies, chassis, and other structural components. They offer high strength and impact resistance, ensuring passenger safety. 3. Manufacturing and machinery: Steel sheets are used in the manufacturing sector for fabricating heavy machinery, equipment, and industrial tools. Their high tensile strength and resistance to wear and tear make them suitable for demanding applications. 4. Appliances and electronics: Steel sheets are commonly used in household appliances like refrigerators, washing machines, and ovens. They provide a sturdy and durable outer casing, protecting the internal components. 5. Energy and power generation: Steel sheets are essential in the power generation industry for constructing power plants, transmission towers, and wind turbines. They can withstand extreme weather conditions and provide structural integrity. 6. Packaging industry: Steel sheets are used for manufacturing packaging materials like cans, drums, and containers. They ensure the safety and preservation of goods during transportation and storage. 7. Aerospace and defense: Steel sheets find applications in the aerospace and defense sectors for manufacturing aircraft parts, missiles, and armored vehicles. Their high strength-to-weight ratio is crucial for these industries. 8. Furniture and interior design: Steel sheets are used in the production of furniture, fixtures, and decorative elements. They offer a modern and sleek appearance while providing durability and stability. Overall, steel sheets are highly versatile and find applications in numerous industries due to their strength, durability, and diverse range of properties.

- Q: Are steel sheets suitable for automotive body parts?

- Yes, steel sheets are suitable for automotive body parts. Steel is a commonly used material in the automotive industry due to its strength, durability, and ability to withstand high impact. Steel sheets provide excellent structural integrity and can be easily formed into various shapes to create automotive body panels. Additionally, steel is cost-effective and readily available, making it a preferred choice for manufacturing automotive body parts.

- Q: Can the steel sheets be used for kitchen countertops?

- Yes, steel sheets can be used for kitchen countertops. Steel is a durable and long-lasting material that can withstand high temperatures, making it suitable for kitchen use. It is resistant to stains, scratches, and water damage, making it easy to clean and maintain. Additionally, steel countertops can provide a sleek and modern aesthetic to any kitchen. However, it is worth noting that steel can be prone to scratches and dents, so it is important to exercise caution when using sharp utensils or heavy objects on the countertop.

- Q: Are steel sheets suitable for automotive applications?

- Yes, steel sheets are suitable for automotive applications. Steel is a strong and durable material that provides excellent structural integrity and crash protection in vehicles. Additionally, steel sheets can be easily formed and shaped to meet the complex design requirements of automotive components.

- Q: How do steel sheets handle bending or flexing?

- Steel sheets are known for their excellent strength and rigidity, making them highly resistant to bending or flexing. The inherent properties of steel, such as its high tensile strength and stiffness, allow it to withstand substantial external forces without deforming. Steel sheets can handle bending or flexing to a certain extent without compromising their structural integrity, making them suitable for a wide range of applications. When steel sheets are subjected to bending or flexing forces, they undergo a process known as elastic deformation. This means that the steel will temporarily change shape under the applied load, but it will return to its original form once the load is removed. This elasticity is due to the crystalline structure of steel, which allows it to absorb and distribute the stress evenly throughout its structure. However, it is important to note that steel sheets do have a limit to their bending or flexing capabilities. Beyond a certain point, the applied load can cause the steel to undergo plastic deformation, which results in permanent changes to its shape. This can lead to the formation of cracks or fractures in the material. The maximum amount of bending or flexing that steel sheets can tolerate before experiencing plastic deformation is determined by factors such as the thickness of the sheet, the grade and type of steel used, and the specific application requirements. To enhance the flexibility of steel sheets, certain processes such as cold rolling or annealing can be employed. Cold rolling involves passing the steel sheet through rollers at ambient temperature, which not only increases its strength but also improves its ability to withstand bending or flexing forces. Annealing, on the other hand, involves heating the steel to a specific temperature and then cooling it slowly to relieve internal stresses, making it more ductile and less prone to cracking. In conclusion, steel sheets are highly capable of handling bending or flexing due to their inherent strength, rigidity, and elasticity. However, it is essential to consider the specific application requirements and the limitations of the steel sheet to ensure its performance and longevity.

- Q: What is the tensile strength of the steel sheets?

- The tensile strength of steel sheets can vary depending on the specific grade and thickness of the steel. Generally, steel sheets have a tensile strength ranging from 370 to 1,500 megapascals (MPa). However, it is important to note that different types of steel sheets have different tensile strength values. For example, low carbon steel sheets typically have a tensile strength of around 370 to 550 MPa, while high-strength low alloy (HSLA) steel sheets can have tensile strengths ranging from 450 to 1,200 MPa. Additionally, the thickness of the steel sheets can also affect their tensile strength, with thicker sheets generally having higher tensile strength values. Therefore, it is crucial to consult the specifications provided by the manufacturer or supplier of the steel sheets to determine the precise tensile strength for a particular grade and thickness.

- Q: Can steel sheets be bent or formed into different shapes?

- Yes, steel sheets can be bent or formed into different shapes through various processes such as heating, rolling, or using specialized machinery like press brakes.

- Q: Are the steel sheets resistant to impact or denting?

- Yes, steel sheets are generally resistant to impact and denting due to their high strength and durability.

- Q: What are the standard dimensions of steel sheets?

- The standard dimensions of steel sheets can vary depending on the specific application and industry requirements. However, common standard dimensions for steel sheets typically include thicknesses ranging from 0.5mm to 25mm, widths ranging from 600mm to 2000mm, and lengths ranging from 2000mm to 6000mm.

- Q: Can steel sheets be used in construction?

- Certainly, construction can definitely make use of steel sheets. Due to their strength, durability, and versatility, steel sheets are commonly employed in construction ventures. They find application in diverse areas such as roofing, walls, flooring, and structural components. Steel sheets possess a remarkable tensile strength, rendering them capable of enduring heavy loads and extreme weather conditions. Moreover, steel sheets exhibit fire-resistance, termite-resistance, and a long lifespan, making them a dependable option for construction projects. Additionally, steel sheets offer ease of fabrication, enabling customization and flexibility in design. In summary, steel sheets serve as an outstanding option for construction, ensuring structural integrity, durability, and design adaptability.

Send your message to us

Galvalume Corrugated Steel Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords