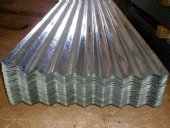

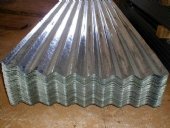

GI GL PPGI PPGL Corrugated sheets

- Loading Port:

- TIANJIN

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 30000ton m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

We specialize in manufacturing galvanized steel coil, galvalume steel coil, prepainted steel coil and galvanized corrugated sheets.

Nowadays our company has grown up to a collectivized company . We are grateful to the cooperation partner who`s grown with us all the way. We hope we could make more friends from all over the world. Under the joint efforts of both sides we believe that we will continue to achieve win-win results based on mutual trust and mutual support.

Quick Details

| Standard: | Grade: | Thickness: | |||

| Place of Origin: | Brand Name: | Model Number: | |||

| Type: | Technique: | Surface Treatment: | |||

| Application: | Special Use: | Width: | |||

| Length: | Based Material: | Material: | |||

| Zinc Coated: | Spangle: | Shape: | |||

| Galvanized Type: | Business: | Payment Terms: | |||

| Packaging: | Delivery Detail: |

Packaging & Delivery

| Packaging Detail: | Fully seaworthy export packing with paper tube Each coil is wrapped in water-proof paper. |

| Delivery Detail: | about 15 days after the deposit if the quantity below 500 ton. |

Specifications

Corrugated gi/gl/ppgi Sheet

1.Thickness: 0.13mm-1.0mm

2.Width:750mm-1250mm

3. z40-z150g/m2

4.ISO 2000,SGS

our corrugated steel sheet:

GI Corrugated Steel Sheet | ||

No. | Item | Specification |

1 | Product Name | GI corrugated steel roofing sheet |

2 | Effective Width | 650mm to 1250mm |

3 | Thickness | 0.13mm-0.8mm |

4 | Material | Aluzinc or zinc coating PPGI steel coil |

5 | Zinc-coating | 40g/m2-150g/m2 |

6 | Color | white,blue or any RAL colors |

7 | length | 1m-11.8m according to the container |

8 | top color coating | 12um-25um |

9 | Back color coating | 7um-10um |

10 | HRB | 50-95 |

11 | Certificate system | ISO9001:2000 |

12 | base plate | hot-dipped galvanised steel sheet |

13 | Characters | light weight. Waterproof and fireproof and easy construction |

14 | Stardard | ASTM,JIS, DIN, GB |

- Q: Are the steel sheets heat-resistant?

- Indeed, steel sheets exhibit remarkable resistance to heat. Renowned for its elevated melting point, steel proves to be an apt substance for situations that entail exposure to extreme temperatures. It possesses the ability to endure heat without distorting or compromising its structural integrity. Nonetheless, the precise extent of this heat resistance may fluctuate contingent upon the distinct variety of steel and its composition. Certain steel alloys are intentionally formulated to possess an even greater resistance to heat, rendering them suitable for implementation in sectors like aerospace, automotive, and construction, where elevated temperature environments are prevalent.

- Q: Can steel sheets be used for electrical transformer cores?

- Yes, steel sheets can be used for electrical transformer cores. Steel is a common material used for transformer cores due to its magnetic properties and ability to efficiently transfer and distribute electrical energy. The laminated core design of stacked steel sheets reduces energy losses through eddy currents and helps in transforming voltage levels effectively.

- Q: Are steel sheets suitable for fire-resistant applications?

- Steel sheets are indeed appropriate for applications that require resistance to fire. Steel has gained a reputation for its exceptional fire resistance properties, primarily because of its high melting point and its reluctance to ignite or facilitate the spread of fire. Steel sheets can be employed in an array of fire-resistant applications, including fire doors, fire-rated walls, and fireproof enclosures. Moreover, steel sheets can be combined with other fire-resistant materials, like fire-resistant coatings or insulation, to augment their fire resistance even further. In general, steel sheets are a dependable option for fire-resistant applications owing to their robustness, potency, and capacity to endure high temperatures.

- Q: Can steel sheets be used for signage purposes?

- Yes, steel sheets can be used for signage purposes. Steel sheets are durable and can withstand harsh weather conditions, making them suitable for outdoor signage. They can be cut, shaped, and welded into various sizes and designs, providing flexibility in creating custom signage. Steel sheets can also be painted or coated with different finishes to enhance aesthetics and ensure longevity. Additionally, steel sheets are sturdy and can be mounted securely, making them ideal for large and heavy signage installations.

- Q: What is the hardness of steel sheets?

- The hardness of steel sheets can vary depending on the specific type and grade of steel, but generally, steel sheets have a high level of hardness ranging from 30 to 60 on the Rockwell C scale.

- Q: Can steel sheets be used in energy applications?

- Yes, steel sheets can be used in energy applications. Steel is a versatile material with excellent strength and durability, making it suitable for various energy-related uses. It is commonly used in the construction of power plants, wind turbines, and transmission lines due to its ability to withstand high temperatures, corrosion, and mechanical stress. Additionally, steel sheets can be utilized in the manufacturing of energy storage systems, such as batteries and fuel cells, due to their electrical conductivity and stability.

- Q: What are the common thicknesses for aluminum-coated steel sheets?

- The common thicknesses for aluminum-coated steel sheets range from 0.015 inches to 0.125 inches.

- Q: Can steel sheets be used for automotive wheels?

- No, steel sheets are not typically used for automotive wheels. Wheels are usually made from aluminum alloy or magnesium alloy, as these materials provide better strength-to-weight ratio and improve the overall performance and fuel efficiency of the vehicle.

- Q: What is the difference between a black and pickled steel sheet?

- A black steel sheet refers to a plain carbon steel sheet that has not undergone any additional surface treatment. It has a characteristic dark appearance due to the presence of an iron oxide scale on its surface. On the other hand, a pickled steel sheet has undergone a surface treatment process called pickling, which involves removing the oxide scale using an acid solution. This treatment results in a clean and smooth surface, making it more suitable for further processing or application.

- Q: Are steel sheets prone to warping or buckling?

- Yes, steel sheets are prone to warping or buckling due to external factors such as heat, pressure, or improper handling.

Send your message to us

GI GL PPGI PPGL Corrugated sheets

- Loading Port:

- TIANJIN

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 30000ton m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords