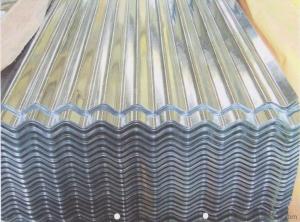

PPGI PPGL PPAL GI GL Color coted steel coil

- Loading Port:

- QINGDAO

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

The company produces and sells various specifications and colors of color steel plate, quality assurance, welcome to consult and negotiate.

Specification: thickness: 0.10-2.0mm

Width: 750-1250mm

Color: according to the color card or according to customer requirements.

Coating thickness: normal coating or customized according to customer requirements.

Base plate type: hot galvanized base plate, aluminum zinc base plate, etc.

- Q: What's the difference between a cold plate and a hot plate?

- With the continuous casting slab or as raw material hot plate, hot plate, hot plate, after reheating furnace heating, descaling into the roughing mill of high pressure water, roughing material by cutting head, tail, and then enter the finishing mill, the implementation of the computer controlled rolling, after finishing through the laminar cooling (computer controlled cooling rate) and coiler, become straight hair volume.

- Q: What are the standards for cold rolling and hot rolling of stainless steel? What's the difference?

- The free torsion rigidity of hot rolled steel is higher than that of cold rolled steel, so the torsion resistance of hot rolled steel is better than that of cold rolled steel.

- Q: Stamping process classification

- Is a kind of basic stamping process mould separation material, which can be directly made of flat parts or other stamping processes such as bending, drawing and forming are blank, also can be in the stamping forming has been carried on the incision, trimming etc.. Blanking is widely used in automotive, household appliances, electronics, instruments, meters, machinery, railways, communications, chemicals, light industry, textiles and aerospace industries. Blanking accounts for about 50% to 60% of the whole stamping process. Bending: bending of sheet metal, fittings, and profiles into a plastic forming method of angles, curvatures, and shapes. Bending is one of the main processes widely used in the production of stamping parts. The bending of metal material is essentially an elastic-plastic deformation process, after unloading, the workpiece will produce the direction of the elastic recovery, called rebound. Springback affects the accuracy of the workpiece, and it is the key technology that must be considered in the bending process.

- Q: What kind of steel is Q2351?

- Q235 ordinary carbon structural steel, also known as A3 plate.The common carbon structural steel Pu plate is a kind of steel material.

- Q: Stainless steel composite process

- Rolling composite method is a method of producing metal stainless steel composite plate by using pressure process. There are two kinds of cold rolling composite and hot rolling composite. The basic principle is the need of two kinds of metal compound in certain proportion and requirements into the rolling mill, rolling mill in great pressure, or with thermal effect by combining the two kinds of metallic composite plate occurred in the whole cross section of plastic deformation, prompting to composite surface deformation, clean and activation. Along with the formation of planar metallurgical bonding. The basic requirement of rolling compound is the rolling equipment with great pressure and the professional technology of producing composite board. The stainless steel composite plate made by this method has the following advantages: (1) it can enlarge the dimension (length and width) of the composite panel. (2) the production cost is low, and the products are competitive in the market. (3) from raw materials to finished products can be continuously produced, suitable for mass production. (4) it is easy to set up a production line with higher automation. (5) the composite material is not easy to be contaminated by the base material, the combination property is good, and the product quality is stable.

- Q: What is a metal layered composite?

- Diffusion bondingDiffusion bonding is a method of bonding under the condition that the parent material is deformed below the melting point temperature of the base metal and the atomic diffusion occurs at the interface.

- Q: How to recognize the raw plate in the steel plate?

- Steel plate called "cooked", probably "cold plate" and "hot plate" points, cold plate is cold-rolled steel short.

- Q: What's the difference between stainless steel strip 304 hot rolling and cold rolling?

- The production process is different. The hot rolled plate is usually medium thick plate. The slab is heated to be rolled to thickness and then pickled.

- Q: What are the raw materials and production processes of steel?

- Steel is an important material for national construction and the realization of the four modernization indispensable, its wide application, wide variety, according to the different steel profile is generally divided into sections and plates, pipes and metal products four categories, in order to facilitate the organization of steel production, supply management and order management, and divided into heavy rail, light rail, large steel, and steel, small steel, steel cold-formed steel, high-quality steel, wire rod, steel plate, steel sheet, electrical silicon steel sheet, strip steel, seamless steel pipe, welded steel pipe, steel, metal products and other varieties.

Send your message to us

PPGI PPGL PPAL GI GL Color coted steel coil

- Loading Port:

- QINGDAO

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot Searches