Color Coated Galvanized Steel Coils PPGI/PPGL

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Surface Treatment:Coated

Technique:Galvanized

Standard:JIS

Application:Container Plate

Edge:Mill

Stock:Stock

Steel Grade:CGCC, Dx51d, SGCC

Color:Ral 1015, 5002, 6005, 8017, 9002, 9006, 9010 etc.

Thickness:0.16-1.0mm

Width:914/1000/1200/1219/1220/1250mm

Base Metal:Galvanized or Galvalume Steel

Zinc-Coating:Z50-150G/M2 or Az40-100G/M2

ID Coil:508mm

Coil Weight:3-5 Mt

Painting:20-25miu on Top / 5-8miu on Back

Type of Coating:PE Smp PVDF

Export Markets:North America, South America, Southeast Asia, Eastern Asia

Additional Info.

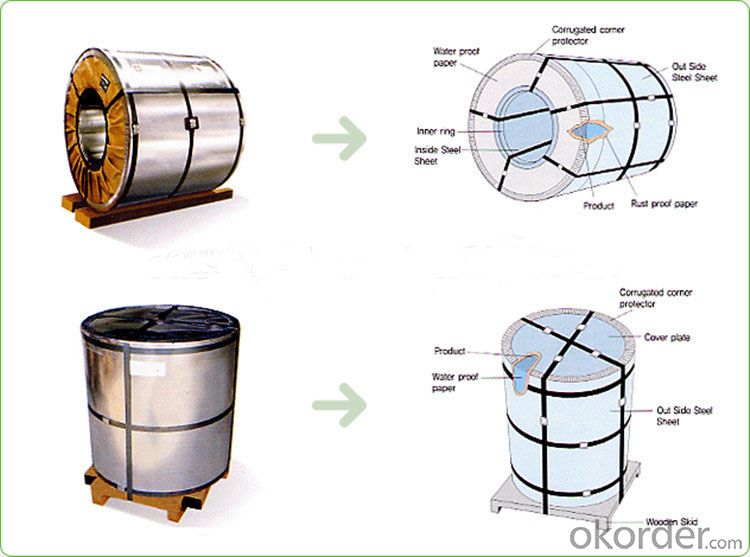

Packing:Standard Export Seaworthy Packing In20′′ Container

Standard:0.14-1.0*914-1250*C

Origin:China

HS Code:72107010

Production Capacity:100000tons Per Year

Product Description

Color-coated Galvanized/Galvalume Steel Coil (PPGI/PPGL)

1. Techinical standard: EN10169

2. Grade: TDX51D, TSGCC

3. Color: Ral standard or according to customers' requirment

4. Thickness: 0.14-1.0mm (0.16-0.8mm is the most advantage thickness)

5. Width: 600-1250mm (610/724/820/914/1000/1200/1219/1220/1250mm)

6. Base metal: Galvanized / galvalume steel

7. Finish Painting: 15-20miu PE on top 5-8miu EP on back

8. Color: Ral standard

Acceptable payment term and way?

T/T,L/C, T/T + L/C, D/P

Acceptable price term

FOB CNF CIF DDU CPT

Do you accept OA payment terms?

Yes, sure, but it normally depending on the order value

Do you have QC team?

Yeah, sure, our QC team is very important, they will keep the qualitycontrol for our products.

What is the validity of your quotation?

Normally 7 days.

What is your advantage?

24 hour quick response /Customer oriented/ Credit foremost/ Top quality Excellent

What is your acceptable payment term?

TT,LC,OA etc

- Q: How are steel coils inspected for surface quality?

- Steel coils are inspected for surface quality through a visual examination process, where trained inspectors closely examine the surface of the coils for any defects or irregularities. This includes looking for scratches, dents, stains, or any other imperfections that may affect the quality of the steel. Additionally, advanced technologies such as automated scanning systems or cameras may also be used to detect and analyze any surface defects that are not easily visible to the naked eye.

- Q: What are the safety precautions when working with steel coils?

- When working with steel coils, it is important to follow several safety precautions. Firstly, workers should always wear the appropriate personal protective equipment (PPE) such as safety glasses, gloves, and steel-toed boots to protect themselves from potential hazards. Additionally, it is crucial to ensure that the work area is clean and free from any debris or obstacles that may cause accidents or tripping. Proper manual lifting techniques should be employed to avoid strain or injury when handling heavy steel coils. Workers should also be trained in the proper use of equipment such as cranes or forklifts to safely transport and store the coils. Regular inspections of equipment and proper maintenance should be conducted to prevent any malfunctions or accidents. Lastly, employees should be aware of emergency procedures and have access to fire extinguishers and first aid kits in case of any unexpected incidents. Overall, prioritizing safety measures and being vigilant can greatly minimize the risks associated with working with steel coils.

- Q: The hard industrial steels. If there's a bunch, what's a rough average? Also, what is is measured in?

- Hrc Steel

- Q: What are the different types of edge conditions in steel coils?

- Some of the different types of edge conditions in steel coils include mill edge, slit edge, and sheared edge. Mill edge refers to the original edge produced during the steel manufacturing process. Slit edge is created when the steel coil is cut into narrower strips. Sheared edge is formed when the coil is trimmed using a cutting tool. These various edge conditions have different characteristics and can impact the usability and appearance of the steel coils.

- Q: What are the common applications of steel coils in construction?

- Steel coils are commonly used in construction for various applications such as structural components, including beams, columns, and trusses. They are also used for roofing and cladding systems, as well as in the fabrication of reinforcing bars and precast concrete elements. Additionally, steel coils are utilized in the manufacturing of pipes, tubes, and sheet metal products, serving as a crucial material in the construction industry.

- Q: How are steel coils used in the production of heating systems?

- The production of heating systems relies on the utilization of steel coils in various ways. One primary application of steel coils in heating systems involves their incorporation in the construction of heat exchangers. Heat exchangers serve a vital purpose in the transfer of heat from one medium to another within the heating system. Typically, the steel coils are shaped into tubes or fins, which maximize the surface area for optimal heat transfer. In a typical heating system setup, the steel coils allow hot gases or liquids to pass through them, while another medium, such as air or water, flows over or through the coils. This arrangement facilitates the efficient transfer of heat energy from the hotter medium to the cooler one, effectively heating the air or water for distribution throughout the heating system. Steel coils are also employed in the production of radiant heating panels or floor heating systems in heating applications. In these instances, the steel coils are usually embedded within a panel or positioned beneath the flooring. When electricity or hot water passes through the coils, they heat up and emit heat to the surrounding environment. This particular heating system type boasts high efficiency and ensures a comfortable and evenly distributed heat output. Moreover, steel coils are integral components of heating systems such as boilers, furnaces, and heat pumps. These heating system units often require the use of steel coils due to their excellent heat transfer capabilities and durability. The integration of steel coils into the design of these units guarantees efficient and reliable heat generation and distribution. In summary, steel coils play a critical role in the production of heating systems as they enable efficient heat transfer, provide durability, and facilitate the generation and distribution of heat.

- Q: Hi! does anyone know where can i find a building with a structure of steel frames, i need to do an analysis for school so i need joint details, girder details and such! PLEASE help me! thanks

- if u need to analyse a steel framed structure for joint details the best example would be of a mechanic workshop...the truss of such a workshop is always supported on a portal frame and in most of the case thats a steel structure...do keenly observe the joints at the footing plates that is connected to the girder section...nd also observe the joints in truss of such a frame....myslf m a civil engg. student.

- Q: I want to know what to my wash stainless fridge door with before applying the stainless steel polish.

- if you first wash it with hot soapy water to get rid of any grease. Then make a solution of vinegar and water in a spray, spray the solution onto stainless steel, wipe down, then polish dry with a clean cloth, you will not need stainless steel polish as it will come up lovely and clean and shiny.

- Q: can u use stainless steel to make a coin? why or why not? answers based on facts plz.

- Stainless steel has been used by some countries to make coins, but it's not an ideal metal. When a coin is struck, a die comes down and strikes the blank with many tons of force (the blank is also sitting on top of another die--one has the image on the obverse (front) of the coin, while the other die has the image of the reverse of the coin). When the die strikes the blank, the force causes the metal in the blank to flow into the recesses of the die. The problem with stainless steel is that it doesn't want to flow into the die. To get an image, either the relief (how high the raised portion of the design will be) has to be very low, and the coin has to have a simple design, or they have to greatly increase the pressure of the strike. This slows the coining press down, and greatly shortens the life of the dies.

- Q: What are the different types of steel coil edge treatments?

- There are several different types of steel coil edge treatments used in the manufacturing and processing of steel coils. These treatments are done to enhance the edge quality, protect against damage, and facilitate handling and processing of the coils. Some of the common types of steel coil edge treatments include: 1. Mill Edge: This is the standard edge treatment provided by the steel mill. It is the raw edge of the steel coil that has been produced during the hot rolling process. Mill edge is typically sharp and may have some irregularities. 2. Slit Edge: Slit edge is a type of edge treatment where the coil is slit to the desired width, and the edges are then processed to remove any burrs or unevenness. Slit edge coils have smoother edges compared to mill edge coils. 3. Deburred Edge: Deburring is a process that removes any sharp or rough edges from the coil. It is done using specialized equipment or techniques to create a smoother and safer edge. Deburred edges are commonly used in applications where safety and handling are critical. 4. Rounded Edge: Rounded edge treatment involves rounding the edges of the coil to reduce the risk of damage during handling and processing. This treatment is often used in applications where the coil needs to be uncoiled or fed into machinery without causing any damage. 5. Beveled Edge: Beveling is a process where the edges of the coil are chamfered or cut at an angle. Beveled edges are used in applications where easy insertion, joining, or welding of the coil is required. The beveling process also helps to improve the strength and durability of the edge. 6. Sheared Edge: Shearing is a cutting process where the coil is cut to the desired width using high-pressure blades or scissors. Sheared edge treatment provides a clean and straight edge, free from burrs or irregularities. It is commonly used in applications where precise dimensions and a smooth edge are required. These are just a few of the different types of steel coil edge treatments commonly used in the industry. The choice of edge treatment depends on the specific requirements of the application, such as handling, processing, safety, and aesthetics.

Send your message to us

Color Coated Galvanized Steel Coils PPGI/PPGL

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords