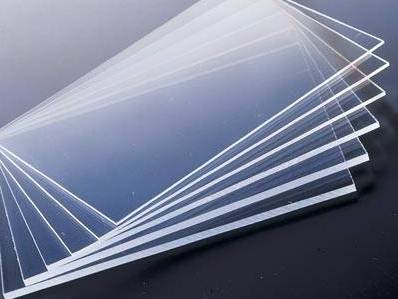

Solar FTO Glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 m2 m²

- Supply Capability:

- 10000 m2 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

FTO Glass or AZO Glass is a kind of TCO glass mainly used for producing thin film solar cells as substrate/front TCO glass or seal glass/back glass. The right balance between transmittance, haze and conductivity of the TCO coating enable it to improve the cell efficiency of thin film solar cells embedded in photovoltaic modules.

Features of Solar FTO Glass:

Light transmittance: >80%

Sheet resistance: 7-15Ω

Haze: 10%-50%

good laser etching properties

good weatherability and durability

High light transmittance, high mechanical strength, high planeness.

Product’s Description:

Type | TCO Glass(Ultra Clear Float Glass) |

Conductive Coating | SnO2: F Based or ZnO: Al Based |

Deposition | CVD |

Applications | Front glass or back glass for thin film solar cells (a-Si: H solar cells, μc-Si tandem solar cells and CdTe solar cells). |

Specifications of Solar FTO Glass:

Thickness: 3.2mm, 4mm,

Size: customized size

Applications of Solar FTO Glass:

FTO Glass or AZO Glass is widely applied in a-Si: H solar cells, μc-Si tandem solar cells and CdTe solar cells because of its potentials to lower the reflectivity between the interface and the absorber, to increase the light path into the absorber and to trap the solar energy into the absorber.

- Q: What kind of material is glass made of?

- 1. isotropic particles of glass are arranged irregularly in general, but are statistically uniform, so that their physical and chemical properties are the same in any direction. The crystal is anisotropic. Examples: resistivity, thermal conductivity, transmissivity, refractive index, etc..2. there is no fixed melting point. Glass changes from solid to liquid and varies gradually over a range of temperatures. The crystal is determined by melting point, for example, (water ice crystals) in C melt 0 Eve joy. This property of glass makes it possible to be shaped by blowing, pulling, pressing, and other methods.3. tunability of composition and properties. The properties of the glass may vary continuously and gradually within a certain range with their properties. The crystal has a fixed component and a definite performance. In this way, we can adjust the composition of the glass, so that its performance meets the requirements of the use.

- Q: Twilight wall hollow glass with glass Zha glue with what is best?

- The raw materials of the latter two kinds of insulating glass are glass, aluminium strip, insert angle, butyl glue, double component polysulfide glue or silicone rubber, drying agent and compound sealant.

- Q: How can glass frosting be formulated? What raw materials do you use?

- The frosting frosting liquid before configured with plastic (or bamboo sticks) fully stir until frosting, and then prepare the medicine 80 mesh will be good all the time was filtered, the filtrate into the box (with sand sprinkling), filter residue (crystal) with plastic barrels (good to be frosted glass after the completion of the work, with 80 of the screen will put back the crystal installed frosting solution is dissolved, so repeated operation, the filter residue (crystal) can recycling, prolong the service life of frosting liquid).

- Q: Polypropylene short fiber and glass fiber if different

- Glass fiber and polypropylene fiber are different in proportion, glass fiber will sink in water, and polypropylene fiber is suspended in water;

- Q: Is the balance pad the raw material in the motor?

- Its main function is the use of mechanical energy into electrical energy, the most common is the use of thermal energy, water power, and so on to promote the generator rotor to generate electricity.

- Q: What materials do we need to make glass septic tanks?

- Advantages of glass reinforced septic tanks:Good impermeability:1., high polymer material as the base material, good sealing, never leak.2. construction speed.3. products for factory production of finished products, site construction is fast, and the high water level, rainy season can also be construction.4. clear long cycle.5., the anaerobic fermentation is sufficient, the silt deposition quantity reduces greatly, the clear cutting cycle prolongs 3-4 times, greatly reduces the follow-up operation and the maintenance cost.6., treatment effect is good.7., set aside bins, hierarchical fermentation, sewage discharged in the BOD, COD and other pollutants significantly reduced.8., small footprint.

- Q: Is glass fiber reinforced plastic board fireproof partition board?

- The fire board also called Naihuoban, is based on the pressure in the wood with fireproof veneer made of fireproof performance, sound insulation effect, which belongs to refractory materials, widely used in interior decoration, furniture, kitchen cabinets, laboratory table, wall. General thickness of 17mm and 19 mm two kinds of thickness.

- Q: Samsung LCD panel information

- The power supply needs to look at the output power, the output voltage, such as the 26 inch and 32 inch power supply on the market. Other sizes of LCD, or need to consult manufacturers of power supply, specific parameters

- Q: What's the difference between crystal and ordinary glass?

- Feel: the same volume of crystal glass and ordinary glass weight is not the same. High crystal glass will make you feel calm, heavy feel. Similarly, the lower the crystal glass, the lighter it will be. Ordinary glass weight is more self-evident.

- Q: What materials are needed for the production of glass bottles and what are their proportions?

- The glass is the main component in the manufacturing process of quartz sand, quartz sand is combined with other chemical materials at high temperature (1300 degrees Celsius) crystallized after firing the cooling of the body, with a hard, abrasion resistance, corrosion resistance and high transmittance characteristics, its wide application has a long history.

1. Manufacturer Overview

| Location | Hebei,China (Mainland |

| Year Established | 1999 |

| Annual Output Value | |

| Main Markets | North America South America Eastern Europe Southeast Asia Africa Mid East Eastern Asia Western Europe |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | English,Chinese |

| b) Factory Information | |

| Factory Size: | 30,000-50,000 square meters |

| No. of Production Lines | 3 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | |

Send your message to us

Solar FTO Glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 m2 m²

- Supply Capability:

- 10000 m2 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords