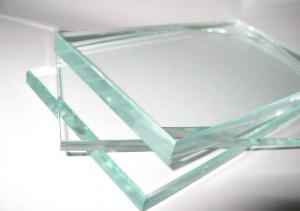

Clear Float Glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 10 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Clear Float Glass of high quality include PDP Glass, automobile glass, mirror glass, coating glass, etc. It has been widely recognized by customers.

Features of Clear Float Glass:

1. Good Panel Quality

2. Excellent Optical Performance

3. Complete Specifications

4. Easy to be processed (being tempered, coated, mirror-made, etc.)

Specifications of Clear Float Glass:

Thickness:3-25mm

Size:

1830*2134mm;1830*2440mm;1830*650;

1650*2134mm;1650*2440mm;

3660*2134mm;3660*2440mm;

3300*2134mm;3300*2440mm;3300*5000mm;3300*6000mm;3300*6500mm

3050*2134mm;1500*2000mm;920mm*1016

customized sizes

Applications of Clear Float Glass:

Clear Float Glass is widely used in electrical panels, optical panels, mirrors, coated glass, automotive glass, building glass, etc.

- Q: What chemicals can be made from glass, paper, detergents, etc?

- Glass: quartz, sodium carbonate, calcium carbonate paper: bark is enough.. cellulose + bleaching agent, such as activated carbon and other detergents, soap bar, sodium stearate

- Q: What is the raw material for making glass?

- The main raw material is quartz sand. Because of the high melting point of quartz sand, it is necessary to add a flux of sodium carbonate (that is, our usual surface base) to molten glass when melting,

- Q: How is glass made? I heard that sand is used, but what is the concrete principle?

- Ordinary glass plate glass, wire glass and quartz glass (also known as crystal glass) a molding. Wired glass as the quartz glass; only a raw material of sandstone or silica or quartz sand.Tempered glass is made of flat glass as raw material for re processing: the cut of the flat glass into the tempering furnace, heating to about 650 degrees, with cold air quenching, glass forming hardening - tempering. Accomplish!

- Q: Why a broken glass film

- It blew the concept of rate, the national standard of our country only glass project on the wall, I do not know whether the other foreign industry to use the toughened glass also has detailed provisions.

- Q: What are the raw materials of glass fiber reinforced plastic?

- If they are bonded together with synthetic resins, they can be made of rigid products of a fixed shape, bearing both tensile and flexural, compressive, and shear stresses.

- Q: Yacht enterprises are purchasing their own raw materials (resin, glass fiber, carbon fiber, etc.), home composite products, accessories?

- I do PVC mesh fabric, and it should be used on the hull of your yacht

- Q: What kind of material is the glass made of?

- The chemical composition of glass is Na2SiO3, CaSiO3, SiO2 or Na2O - CaO - 6SiO2, is the main component of silicate, is an amorphous solid irregular structure. Widely used in buildings for wind and light transmission; of mixtures. There is also colored glass mixed with certain metal oxides or salts, and tempered glass made by physical or chemical methods. Sometimes some transparent plastic (such as polymethyl methacrylate) is also called organic glass.

- Q: Who can tell me the raw material and function of the flashy glass?

- Float and other molding methods, its advantages are: suitable for efficient manufacturing quality of flat glass, such as no wave, uniform thickness, smooth surface, upper and lower are parallel to each other; the scale of the production line is not affected by the forming method, energy consumption per unit of product is low; the finished high utilization rate; easy to scientific management and implementation across the board mechanization, automation, high labor productivity; continuous operation cycle of up to several years, is conducive to stable production; to provide suitable conditions for the on-line production of some new varieties, such as electric float reflective glass, annealing, cold end spraying film glass surface treatment etc..

- Q: Tempered glass and ordinary glass raw materials the same, but the manufacturing method is different, why first heating in rapid cooling, the difference is so great?

- When the glass is heated to a suitable temperature, it cools rapidly, causing a sharp contraction of the glass surface and a compressive stress, while the cooling in the middle of the glass is slower and it is too late to shrink, thus forming a tensile stress and making the glass obtain a higher strength. Generally speaking, the higher the cooling intensity, the greater the strength of the glass.

- Q: Is glass fiber reinforced metal material?

- Glass steel (English: Glass Reinforced Plastic, GRP, or Fiber Reinforced Plastic, English: FRP) also known as glass steel or glass fiber reinforced plastic, is a kind of polymer with epoxy resin as matrix, glass steel or carbon fiber reinforced composite material by composite technology and made.

1. Manufacturer Overview

| Location | Jiangsu, China |

| Year Established | 1994 |

| Annual Output Value | Above US$ 50 Million |

| Main Markets | Asia; Oceania; Mid East; Eastern Europe; North America; South America; Africa; |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 61% - 80% |

| No.of Employees in Trade Department | Above 1000 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | High; Average |

Send your message to us

Clear Float Glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 10 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords