Float Glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25T m.t.

- Supply Capability:

- 500T per day m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

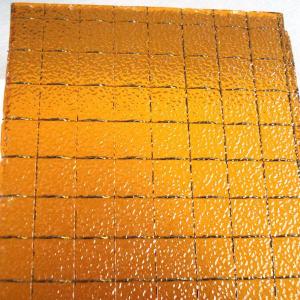

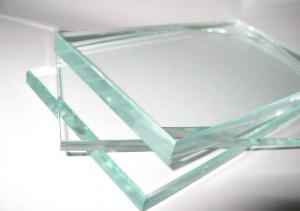

Stained Float Glass 2-19mm , is distortion-free, precision flat and transparent glass. It is made of molten glass which flows through tweel to tin bath and then to lehr. While floating through the molten tin, the glass under the works of gravity and surface tension becomes smooth and flat at both sides.

Model Number: Stained Float Glass 2-19mm

Function: Decorative Glass

Shape: Flat

Structure: Solid

Technique: Stained Glass

Type: Float Glass

Color: Clear; Grey; Blue; Green; Bronze; Pink; Golden etc.

Size: 1830*1220, 3300*2140; 3300*2240; 1830*2440; 3660*2140

Thickness: 2-19mm

Packaging & Delivery of Float Glass

Packaging Details: Wooden crates worthy for ocean and land carriage.

Delivery Detail: Within 25 days after the deposit or L/C

- Q: Is acrylic organic glass?Which is more expensive, acrylic or plexiglass?

- Acrylic board and plexiglass"Organic glass" from English Organic Glass. in recent years in some areas will be made of transparent plastic sheet all are called organic glass, actually this is wrong, it refers to pure acrylic polymethylmethacrylate (PMMA) and the PMMA sheet material, called the acrylic plate.

- Q: The glass door in the shower room is too heavy. What material can be substituted, which is as transparent as glass but lighter than glass?

- You can use the transparent acrylic plate, acrylic plexiglass (acrylic) history in the early 20s, Solomon ha company first invented a new method of acrylic plate used for the polymerization of MMA, the board later called "Oroglas/Plexiglas"

- Q: Is it a vacuum cup with fluorine coating that affects the health?

- Does not affect the health, only in the temperature of more than 200 degrees will be long life of harmful substances.

- Q: Why is toughened glass broken?

- A ton of glass raw materials, at least 3-4 of nickel sulfide crystals, the number of tons of glass made of pieces of a square size glass, which will have 3-4 to explode, which is self depicting the image of.

- Q: Toughened glass and ordinary glass, process and raw materials what is the difference, a little more detailed, thank you

- Glass production process is: raw material crushing, screening, weighing, mixing, high temperature (1600 degrees) melting into glass, glass homogenization, cooling molding, cutting, annealing, cooling, inspection, packaging.The main raw materials are: quartz sand or sandstone, feldspar, soda ash, limestone, dolomite, etc., in addition to soda ash are ore raw materials, need to be broken into the appropriate size.

- Q: Glass raw materials, in addition to quartz sand, what else can be the main raw materials?

- Glass raw materials are: soda ash, limestone, quartz, the ratio is: 1:1:6

- Q: Yacht enterprises are purchasing their own raw materials (resin, glass fiber, carbon fiber, etc.), home composite products, accessories?

- I do PVC mesh fabric, and it should be used on the hull of your yacht

- Q: The difference between glass wool, rock wool, mineral wool

- Originated in Hawaii. Rock wool products are high-quality basalt, dolomite as the main raw material, the high temperature above 1450 DEG after melting by four axis high speed centrifugal centrifuge international advanced fiber, and spray with a certain amount of binder, dustproof oil, water repellent cotton collector after collection, through the pendulum method, and three-dimensional method after cotton spreading curing, cutting, rock wool products form different specifications and applications.

- Q: Medium temperature glass flake clay products

- Due to the relative stretching coefficient of the steel, cement and other material and substrate, so in the case of heat shock resin layer easily cracking and shedding, and glass flake can provide a heat stable layer, which can prevent the substrate cleavage and shedding.

- Q: May I ask what specific aspects of German foam glass and foam glass made in China are?

- Germany first foam glass from the production process is automatic production line, proportion of raw materials, mixing, grinding, into the furnace foaming, stripping, pipeline operations, and 24 hours of uninterrupted production, full computer monitoring, the whole process of online cutting, according to the requirements of automatic generation of the required thickness and size. 100% waste glass as raw material.

1. Manufacturer Overview

| Location | Shandong,China (Mainland) |

| Year Established | 2001 |

| Annual Output Value | Above US$100 Million |

| Main Markets | North America5 South America 22 Eastern Europe 4 Southeast Asia 7 Africa 25 Oceania 6 Mid East 25 South Asia 6 |

| Company Certifications | AS/NZS2208:1996 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao,Tianjin,Dalian |

| Export Percentage | |

| No.of Employees in Trade Department | 11-20 People |

| Language Spoken: | English, Chinese, Spanish, Portuguese, Arabic, French, Russian |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | 6 |

| Contract Manufacturing | OEM Service Offered Design Service Offered Buyer Label Offered |

| Product Price Range | Low and/or Average |

Send your message to us

Float Glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25T m.t.

- Supply Capability:

- 500T per day m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords