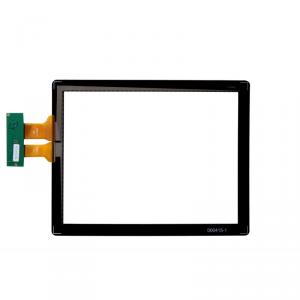

ITO Glass for Display

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 m2 m²

- Supply Capability:

- 10000 m2 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

ITO Glass is manufactured through coating ITO transparent conductive layer on single side or double sides of glass according to the advanced technology of vacuum magnetron sputtering. It is the critical material for producing resistive or capacitive touch screens. When used on LCD, a SiO2 layer should be added before coating ITO layer on glass to prevent the ions of glass substrate from penetrating into the conductive layer. If it is requested for higher transmittance, one or multiple AR (anti-reflective) layers can be added before coating ITO layer on glass, thus making it the high-transmittance ITO conductive glass.

Features of Display ITO Glass:

Resistance Uniformity:≤±0.1

Film Thickness Uniformity:≤±0.1

Good adhesive force

Good etching property

Good resistance to acid and alkali

Specifications of Display ITO Glass:

Thickness: 2.0mm; 1.1mm; 0.7mm; 0.55mm; 0.4mm; 0.3mm; etc. (with ±0.05mm tolerance)

Size:

14*14"; 14*16"; 20*24";

355.6*406.4mm; 370*470mm; 400*500mm,450*550mm;550*650mm; etc.

Resistance:

High (150-500Ω) used for ESD protection, Touch Screen control;

Average (60-150Ω) used for TN-LCD, electronic anti-interference;

Low (<60Ω) used for STN-LCD, transparent circuit board, etc.

Applications of Display ITO Glass:

ITO Glass, as a kind of TCO glass, is mainly used to produce display screen, touch screen, mobile phone panel, home appliance panel and others.

ITO Glass used for TN-LCD/HTN-LCD/STN-LCD/TFT-LCD/PDP/OLED/VFD/LCOS in the application of vehicle, consumer electronics, industrial products, LCD (liquid crystal display):

surface resistance: 3.5-100Ω

thickness: 0.4-1.1mm

ITO Glass used for touch screen in the application of mobile phone, displayer, GPS, PDA, instruments and apparatuses, etc.

surface resistance: 150-600Ω

thickness: 0.4-3.0mm

- Q: Chemical materials and additives needed for the production of glass

- Production process of 1.3.1 glass1. Raw material pretreatment. The bulk raw materials (quartz sand, soda ash, limestone, feldspar, etc.) grinding, so that dry wet raw materialsDry, iron containing raw materials for iron removal, in order to ensure the quality of glass.2, batch preparation. According to the product, the composition of the mixture is slightly different. For example, ordinary float glass batch (calculated in accordance with 1 weight boxes of 50 kilograms), need to consume 33.55 kg of quartz sand, limestone, dolomite, 2.96 kg 8.57 kg 11.39 kg of soda, Glauber's salt 0.55 kg, 3.45 kg, 0.03 kg of feldspar powder etc..3, melting. The glass mixture is heated in a bath or crucible furnace at a high temperature (1550-1600 degrees) to form a liquid glass that is uniform, free of bubbles and conforms to the molding requirements.

- Q: Renovation of the house to buy bricks when how to see the quality of good or bad? What kind of good?

- According to the degree of finish is divided into yaguangyoumianzhuan and light glazed tiles. At present, the ground material with more matte glazed tiles.The tiles (or tiles) is the use of earth embryo (or earth embryo to add some ore powder) after high temperature and high pressure one-time firing, using the surface and bottom of embryo material basically identical (except for the special process such as tiles, tiles in the new fill glaze series). Vitreous tile belongs to all ceramic product. Its abrasion resistance and flexural strength are very high, the water absorption rate (tile water absorption rate is less than 1 per thousand). Before the tiles mainly used for flooring, tiles, as a wall material is mainly used for high-grade Gaestgiveriet Hotel, office space, but now, with the living standard and the improvement of consumption level, the home use tiles for the kitchen wall materials are more and more family.

- Q: What chemicals added to the PVB resin powder can be diluted into a transparent liquid?

- Polyvinyl butyral (Polyvinyl butyral) PVB.... PVB resin itself contains many hydroxyl (OH) radicals, with some thermosetting resin (Thermosetting resin) (Cross linking reaction produced a bridging reaction) to improve chemical resistance and film hardness and excellent coating properties. High transparency (Transparent), (elastic), elastic toughness (Toughness), alkali resistance, oil resistance and flexibility, impact resistance and low temperature. Because of its special chemical structure, so there is a strong combination of glass, metal, ceramic, plastic, leather and wood.

- Q: What is the difference between acrylic board, lotus board, organic board and PVC board?

- Lotus board (also known as Teflon plate) lotus board single sided composite PVC foam board, ABS lotus board, acrylic panels, ABS surface can not be used for outdoor. Furong sheet is a new kind of chemical material. It is made of polyethylene as main raw material, adding various auxiliaries, and has been formed by chemical bridge foaming, and the single side composite PVC board.

- Q: What kind of material is made of automobile glass?

- Compared with ordinary glass, automotive glass is glass, broken is very small granular, may reduce damage. Automobile front windshield PVB interlayer, strong ability uprising.

- Q: Is glass fiber reinforced plastic board fireproof partition board?

- FRP sheet is not fireproof partition board.

- Q: Medium temperature glass flake clay products

- Glass scales prevent the erosion of base material by water vapor and chemical solvents. The degree of chemical resistance of the substrate or coating varies with the chosen glass material, and the glass scale, which is made of c- glass, has excellent chemical durability.

- Q: May I ask what specific aspects of German foam glass and foam glass made in China are?

- Capacity: the above shows that capacity can not be compared.Quality: a precision controlled machine control, one is artificial ratio, so the quality of the domestic production line is relatively unstable.Because of 100% waste glass, we can really achieve the characteristics of silica, physical weather resistance can be confirmed.

- Q: What kind of film is toughened glass film?

- PP materialPP protective film material is first appeared in the market, the chemical name is polypropylene, no adsorption capacity, generally use glue to stick, tear after the glue will leave marks on the screen, the screen for a long time will be corrosion. This material has been basically eliminated by the vast number of protective membrane manufacturers, but some roadside stalls are still selling, we should pay attention to!

- Q: What are the production processes and raw materials of float glass?

- Float glass production process refers to the glass liquid in molten metal floating on the surface of the flat glass production process. The production process of float glass is to select the raw material needed for the production of glass according to the designed glass composition, and weigh various raw materials according to the designed material, and then prepare the mixture by mixing.

1. Manufacturer Overview

| Location | Hebei,China (Mainland |

| Year Established | 1999 |

| Annual Output Value | |

| Main Markets | North America South America Eastern Europe Southeast Asia Africa Mid East Eastern Asia Western Europe |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | English,Chinese |

| b) Factory Information | |

| Factory Size: | 30,000-50,000 square meters |

| No. of Production Lines | 3 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | |

Send your message to us

ITO Glass for Display

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 m2 m²

- Supply Capability:

- 10000 m2 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords