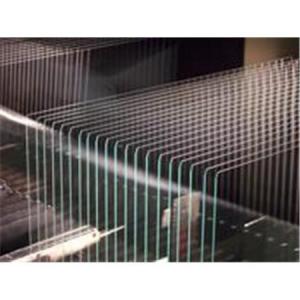

ITO Glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 10 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

ITO Glass is manufactured through coating ITO transparent conductive layer on single side or double sides of glass according to the advanced technology of vacuum magnetron sputtering. It is the critical material for producing resistive or capacitive touch screens. When used on LCD, a SiO2 layer should be added before coating ITO layer on glass to prevent the ions of glass substrate from penetrating into the conductive layer. If it is requested for higher transmittance, one or multiple AR (anti-reflective) layers can be added before coating ITO layer on glass, thus making it the high-transmittance ITO conductive glass.

Features:

Resistance Uniformity:≤±0.1

Film Thickness Uniformity:≤±0.1

Good adhesive force

Good etching property

Good resistance to acid and alkali

Performance Parameters:

Specifications:

Thickness: 2.0mm; 1.1mm; 0.7mm; 0.55mm; 0.4mm; 0.3mm; etc. (with ±0.05mm tolerance)

Size: 14*14"; 14*16"; 20*24";

355.6*406.4mm; 370*470mm; 400*500mm,450*550mm;550*650mm; etc.

Resistance:

High (150-500Ω) used for ESD protection, Touch Screen control;

Average (60-150Ω) used for TN-LCD, electronic anti-interference;

Low (<60Ω) used for STN-LCD, transparent circuit board, etc.

Applications:

ITO Glass, as a kind of TCO glass, is mainly used to produce display screen, touch screen, mobile phone panel, home appliance panel and others.

ITO Glass used for TN-LCD/HTN-LCD/STN-LCD/TFT-LCD/PDP/OLED/VFD/LCOS in the application of vehicle, consumer electronics, industrial products, LCD (liquid crystal display):

surface resistance: 3.5-100Ω

thickness: 0.4-1.1mm

ITO Glass used for touch screen in the application of mobile phone, displayer, GPS, PDA, instruments and apparatuses, etc.

surface resistance: 150-600Ω

thickness: 0.4-3.0mm

- Q: How to distinguish between good and bad glass fiber reinforced plastic?

- Glass fiber reinforced plastic used for raw materials, resin, glass fiber reinforced plastic fiber silk, filler, calcium powder to 1:1:1 ratio configuration, high-quality glass fiber reinforced plastic choose high-quality resin: unsaturated ortho benzene resin 196, colorless transparent. Low viscosity, low heat release, low shrinkage, high speed cure, high speed compatibility and gloss.

- Q: How can the invisible gauze of screen window increase its pressure resistance (glass fiber material)?

- There's no problem with fiberglass mesh.

- Q: What chemicals added to the PVB resin powder can be diluted into a transparent liquid?

- 1) PVB resinPVB intermediate membrane is mainly made of PVB resin..PVB resin is a macromolecule compound obtained by the reaction of polyvinyl alcohol and polyvinyl alcohol under the catalysis of strong acidPVB resin is non-toxic, odorless, non corrosive, non flammable, has good light transmittance, insulation, weather resistance, abrasion resistance, water resistance, oil resistance, aging resistance, adhesive and transparent special properties of inorganic and organic glass. Sandwich materials can be used as safety glass, and can be made transparent other materials used.2) plasticizersPlasticizer 3G8 used in PVB intermediate film has good phase solubility with PVB resin, and has good cold resistance, heat resistance and so on3) additivesIn addition to the above two main raw materials, PVB intermediate membrane, in order to adjust the adhesive force, improve the weather resistance and isolate ultraviolet radiation, also added a relay regulator, antioxidant, UV absorbers and other additives

- Q: Aluminum alloy window glass tape, how fast loading?

- The above two methods can only use single material, that is dry material or wet material. If the wet material is used, the first side is fixed and the other side is injected with glue and then injected onto the side. Both the inner mounting method and the outboard mounting method are best for both sides using wet material. The watertight and air tightness and the best effect of glial sickness, it is best to use silicone sealant for good. For ordinary simple aluminum alloy doors and windows, the use of single glass, fixed glass, both inside and outside the use of dry materials. For the Aluminum Alloy windows advanced commonly used sandwich or hollow glass, glass raw materials used by the heat absorbing glass processing or colored glass, glass were used for fixing the wet material or mixed material.

- Q: Could you tell me that three yuan ethylene propylene (EPDM) rubber can resist ethylene glycol?

- It should be possible to analyze from the following text. The polarity of ethylene glycol is greater than that of methanol, and it must be polar solvent.EPDM has good resistance to polar solvents.

- Q: There are several ways of heating the industrial drying tunnel furnace and are different from each other?

- The utility model has the advantages of long service life and high reliability. The heater is made of special electric heating material, and the design power load is reasonable, and the heater adopts multiple protection, so that the safety and the service life of the heater are greatly increased.

- Q: What's the difference between crystal and ordinary glass?

- To strike lightly or with fingers. Crystal glass can produce metal crisp sound, and waves a beautiful lingering in the air. We will see at the reception banquet, high-end glasses scenes in the movie, a kind of glass between the collision sound is. And high school, low grade crystal glass sound is also different. Like some low-end crystal glass or ordinary glass voice is relatively boring.

- Q: The younger brother wants to know how the octagonal bead is produced Do you use one side of the machine to grind it? What kind of material is usually used in China? Is the price fixed according to the material used?

- C grade crystal beads: batch of beads and emery particles mixed, polished together in the polishing machine, and then mixed with polishing powder, batch polishing, and thus again!

- Q: What materials are needed for the production of glass bottles and what are their proportions?

- The manufacturing technology of the use of glass a thousand li a day, increasing by the clock, glass, doors and windows, lamps, such as high-tech electronic components and space technology, are indispensable glass. Our daily contact with most of the "flat glass is" thick to thin for doors and windows, clocks and the use of medical tests, the manufacturing method is that the furnace in the glass slurry level or traction method (also called float) and vertical traction method. After the dissolution of soluble traction after furnace also has the cooling system, cooling after the completion into a "flat glass, flat glass thickness mainly depends on the speed of traction, traction faster, can be manufactured and thinner. Although the ordinary flat glass from the front appears bright transparent, but from the side near the edge is slightly blue, because the amount of glass color depends on the main raw material in the manufacture of glass - quartz sand and iron content of purity. Generally, the thin glass used in the watch industry is superior in quality but expensive in value, mainly because the material used in quartz sand is superior and the iron content is very low (usually under 3/10000).

- Q: Mobile phone film new flexible toughened glass membrane, really is the glass?

- Toughened glass is a kind of prestressed glass, in order to improve the strength of the glass, the methods commonly used in chemistry or physics, formed on the surface of glass glass under compressive stress, first offset surface stress force, so as to improve the bearing capacity of reinforced glass, its wind, cold, impact etc.. The toughened glass protective film is the highest security level for mobile phone screen protection.

1. Manufacturer Overview

| Location | Shanghai, China |

| Year Established | 1984 |

| Annual Output Value | US$ 0.5 Million |

| Main Markets | Mid East; Eastern Europe; North America; Europe; Asia |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai, China |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | English; Chinese; Korean |

| b) Factory Information | |

| Factory Size: | 5,000 square meters |

| No. of Production Lines | |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

ITO Glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 10 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords