Kimmco Glass Wool Insulation

Kimmco Glass Wool Insulation Related Searches

Glass Wool Insulation India Twiga Glass Wool Insulation Fibreglass Wool Insulation Insulation Wool Glass Wool For Soundproofing Glass Wool Thermal Conductivity Glass Wool Insulation Price List Glass Wool Temperature Range Glass Wool Insulation U Value Fiberglass Wall Insulation Glass Wool Tape Glass Wool Price India Kaowool Insulation Glass Wool Manufacturers In India Fiberglass Roll Insulation Glass Wool Price List Mineral Wool Insulation Price List Indoor Window Insulator Fiberglass Blanket Insulation Fiberglass Thermal Insulation Fiberglass Insulation Malaysia Indoor Window Insulation Ceramic Sheet Insulation Fiberglass Insulation Blanket Fireproof Insulation Wrap White Vinyl Backed Insulation Best Wall Insulation 2 Inch Styrofoam Insulation Roof Foam Board Insulation Tamko RoofingKimmco Glass Wool Insulation Supplier & Manufacturer from China

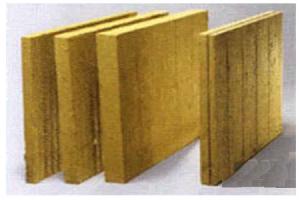

Kimmco Glass Wool Insulation is a range of high-quality insulation products made from glass fibers, designed to provide effective thermal and acoustic insulation for various applications. These products are known for their durability, fire resistance, and energy efficiency, making them a popular choice for both residential and commercial projects. Kimmco Glass Wool Insulation is widely used in construction, industrial, and marine applications, where it helps to reduce heat transfer, minimize noise pollution, and enhance overall comfort levels.The versatile nature of Kimmco Glass Wool Insulation makes it suitable for a variety of usage scenarios, including wall, ceiling, and floor insulation, as well as pipe and equipment wrapping. It can be easily cut and shaped to fit specific spaces, ensuring a perfect fit and optimal performance. This product is also environmentally friendly, as it is made from recycled glass and is non-toxic, making it a safe and sustainable choice for insulation needs.

Okorder.com is a leading wholesale supplier of Kimmco Glass Wool Insulation, offering a vast inventory of this product to cater to the needs of various industries. With a commitment to providing high-quality products at competitive prices, Okorder.com ensures that customers have access to reliable and efficient insulation solutions. By partnering with Okorder.com, customers can benefit from their expertise and extensive range of Kimmco Glass Wool Insulation products, ensuring that their projects are completed with the best possible insulation materials.

Hot Products