Glass Wool Thermal Conductivity

Glass Wool Thermal Conductivity Related Searches

Glass Wool Temperature Range Thermal Conductivity Glass Glass Wool Insulation India Glass Wool For Soundproofing Glass Wool Tape Fibreglass Wool Insulation Twiga Glass Wool Insulation Glass Wool Insulation U Value Kimmco Glass Wool Insulation Glass Wool Price India Glass Wool Manufacturers In India Glass Wool Insulation Price List Glass Wool Price List Insulation Wool Fiberglass Temperature Resistance Electrical Conductivity Of Fiberglass Fiberglass Thermal Insulation Construction Glass Fiberglass Wall Insulation Woven Fibreglass Fiberglass Woven Fabric Fiberglass Woven Fiberglass Mechanical Properties Glass Reinforced Epoxy Glass Fibre Surface Black Glass Fiber Tissue Glass Fiber Mat Mineral Wool Insulation Price List Fiberglass Properties Fiberglass Roll InsulationGlass Wool Thermal Conductivity Supplier & Manufacturer from China

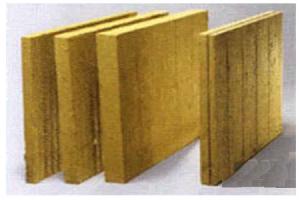

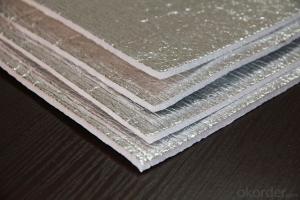

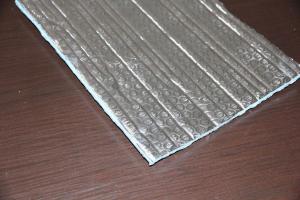

Glass Wool Thermal Conductivity is a type of insulation material made from glass fibers that are spun into a wool-like texture. This material is known for its excellent thermal insulation properties, making it an ideal choice for various applications where heat retention or reduction is necessary. The product is widely used in construction, industrial, and residential settings to provide efficient insulation and energy savings.Glass Wool Thermal Conductivity is employed in a variety of scenarios, such as in walls, ceilings, and roofs, to minimize heat transfer and maintain comfortable indoor temperatures. It is also used in industrial applications like boilers, pipes, and tanks to prevent heat loss and maintain optimal operating conditions. The product's versatility and effectiveness make it a popular choice for those seeking to improve energy efficiency and reduce their environmental impact.

Okorder.com is a leading wholesale supplier of Glass Wool Thermal Conductivity, offering a vast inventory of this high-quality insulation material. As a reliable source for bulk purchases, Okorder.com ensures that customers have access to the quantity and quality they need for their projects. With a commitment to customer satisfaction and a focus on providing top-tier products, Okorder.com stands out as a go-to supplier for Glass Wool Thermal Conductivity.

Hot Products