Glass Fiber Mat

Glass Fiber Mat Related Searches

Fiber Glass Mat Rolls Of Fiberglass Mat Glass Fiber Filler Glass Fibre Surface Fiberglass Woven Roving Combo Mat Chopped Strand Fiberglass Mat Milled Glass Fiber Garage Work Mat Fiberglass Chopped Strand Mat Plastic Mat For Floor Chopped Glass Fiber Warm Floor Mat Glass Grinding Equipment Black Glass Fiber Tissue Glass Wool Tape Car Fiberglass Fibreglass Batt Insulation Fiberglass Patio Roof Fiberglass Roving Fibreglass Mesh Tape Woven Fibreglass Fiberglass Yarn Fiberglass Thermal Insulation Zccy Fiberglass Chopped Strand Mat Fiberglass Insulation Blanket Spaghetti Mat Fiberglass Filament Winding Machine Chopped Fiberglass Resin Fiberglass Model Glass BlockGlass Fiber Mat Supplier & Manufacturer from China

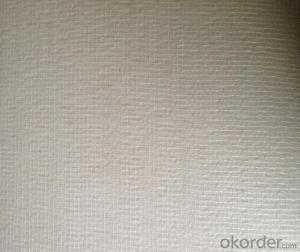

Glass Fiber Mat, also known as glass fiber fabric or fiberglass mat, is a versatile product made from woven strands of glass fibers. It is known for its high strength, durability, and resistance to various environmental factors, making it a popular choice for a wide range of applications. This material is commonly used in construction, automotive, aerospace, and electrical industries due to its ability to provide insulation, reinforcement, and protection.Glass Fiber Mat is widely utilized in various applications such as roofing, flooring, wall insulation, and pipe wrapping. It serves as a reinforcement agent in composite materials, enhancing the strength and stability of the final product. In construction, it is used in the production of fiberglass insulation, providing excellent thermal and acoustic insulation properties. In the automotive industry, it is used in the manufacturing of car bodies, hoods, and trunks, offering lightweight and durable solutions. Additionally, it is employed in the aerospace sector for the production of aircraft components that require high strength-to-weight ratios and resistance to extreme temperatures.

Okorder.com is a leading wholesale supplier of Glass Fiber Mat, offering a vast inventory of this product to cater to the needs of various industries. With a commitment to quality and customer satisfaction, Okorder.com ensures that the Glass Fiber Mat supplied meets the highest industry standards. By partnering with Okorder.com, businesses can access a reliable source of Glass Fiber Mat, ensuring that their projects and products benefit from the exceptional properties of this material.

Hot Products