Glass Fiber Filler

Glass Fiber Filler Related Searches

Glass Fiber Mat Glass Fibre Surface Milled Glass Fiber Chopped Glass Fiber Fiber Glass Mat Car Fiberglass Black Glass Fiber Tissue High Pressure Fiberglass Pipe Glass Reinforced Epoxy Fiberglass Thermal Insulation Chopped Fiberglass Fiberglass Fabric Fiberglass Yarn Fiberglass Pipe Repair Woven Fibreglass S Glass Fiberglass Fiberglass Wall Insulation Fibreglass Fabric Fiberglass Resin Fibreglass Pipes Fibreglass Resin Resin Fiberglass Fiberglass Resin Bulk Fiberglass Insulation Blanket Fiberglass Roll Insulation Fiberglass Filament Winding Machine Glass Wool Tape Fiberglass Woven Fibreglass Mesh Tape Fiberglass RovingGlass Fiber Filler Supplier & Manufacturer from China

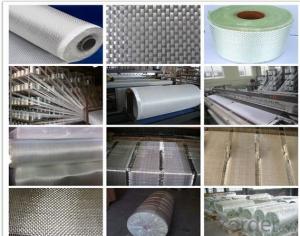

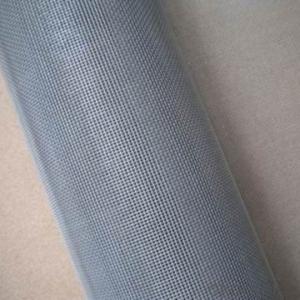

Glass Fiber Filler is a composite material that consists of glass fibers embedded in a resin matrix. This product is specifically designed to provide strength and durability in various applications, making it an ideal choice for a wide range of industries. It is commonly used in construction, automotive, and aerospace sectors, where high-strength and lightweight materials are essential. The versatility of Glass Fiber Filler allows it to be molded into various shapes and sizes, catering to the specific needs of different projects and applications.Glass Fiber Filler is widely used in applications where high mechanical strength and resistance to corrosion are required. It is often employed in the manufacturing of structural components, such as beams, panels, and pipes, due to its excellent load-bearing capabilities. Additionally, it is used in the production of reinforced plastics, where it enhances the material's overall performance and longevity. The product's ability to withstand harsh environmental conditions makes it suitable for both indoor and outdoor applications, ensuring long-lasting performance and minimal maintenance.

Okorder.com is a leading wholesale supplier of Glass Fiber Filler, offering a vast inventory to meet the demands of various industries. As a reputable supplier, Okorder.com ensures that the product is of the highest quality and adheres to industry standards. With a commitment to customer satisfaction, Okorder.com provides competitive pricing and reliable shipping options, making it the go-to source for Glass Fiber Filler.

Hot Products