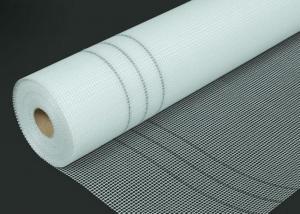

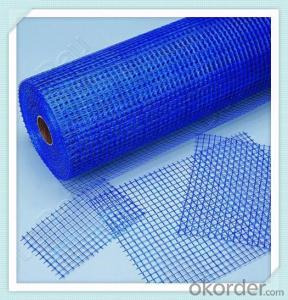

Wholesale Fiberglass Mesh Plaster Reinforcement - Glass Fiber Mesh

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Coated alkaline-resistant (AR) fiberglass mesh fabric

It is made from fiberglass woven roving as its basis material, then is treated by alkali-resistant macromolecule latex. It has excellent properties like high alkali resistance, flexility, tensile strength, etc. It can be widely used in wall heat reservation system, water proofness and preventing cracks.

Common specification:

1. Mesh size: 5x5mm, 4x5mm or 4x4mm;

2. Weight: 80g- -160g;

3. Length/roll: 50m, 100m or 200m;

4. Width/roll: 1m- -2m;

5. Colours: White(standard), blue, green or other colors.

6. Packing: Each roll shrank wrapped, four or six rolls a carton; A 40ft container can be loaded about 80, 000- -150, 000 square meters.

7. Special items can also be done if some changes on weight, width, length, color, or packing if required by customers.

Our main products include: Coated alkaline resistant fiberglass mesh, Glass-fiber reinforced component (GRC) mesh, fiberglass adhesive mesh, self adhesive fiberglass joint tape, mesh used in floor heat supplying system, mesh used for mosaic and back mesh fabric for stone, etc

- Q: The household is screened glass fiber gauze or stainless steel gauze.

- Of course, the glass fiber network is good, the warp and weft bonding. Yarn mesh size is constant, suitable for cleaning,

- Q: How to calculate mesh content?

- The price of mesh material from high to low is successively gold crucible yarn. It is usually from 80 grams to 300 grams per square meter, from a few cents to a few dollars a month. Now the most common is imitated gold pot yarn.

- Q: Are fiber glass lightweight composites?

- Belong to. This definition is not clear, but you want to, ah, metal matrix composite material, there are still light, that can not count ~!"Glass fiber reinforced plastics appeared in the 1940s, not only light, high strength, but also better insulation"

- Q: How to paste gridding cloth?

- Gridding cloth is a material used for for metope grassroots anti-cracking material in home decoration. It is also called crack resistant cloth, crack resistant gridding cloth and generally made of fiberglass. In construction, cloth is used for crack instead of crack resistant cloth.

- Q: Mesh and fiberglass cloth, which is better?

- For building materials, mesh is better; for insulation base cloth, fiberglass cloth is better. And their consts are different, so it depends on your purpose.

- Q: Glass fiber gridding cloth is easy to be broken after being glued.

- The glue matters or the baking process matters.

- Q: How to flang external wall insulation alkali-resistant mesh in window and door? ?

- Wrapping window with insulation board mesh is easy to crack. In order to prevent cracks, the window needs a shear. And pay attention to the sequence of boards. The corner should be cut into knife shape. Do not let the joint fissure be in the window corner, and this is the insulation regulation. Although it will increase costs, it will prevent accidents and maintenance.

- Q: How long does it need to warp fiberglass mesh on window in external wall thermal insulationworks?

- The width of wraping mesh depends on the thickness of thermal insulation boardon the site. The width of pasting on the wall is over 65mm, ang the width of flanging to the board is about 100mm. And the thrown part should be clean.

- Q: How to take samples from alkali-resisting glass fiber gridding cloth?

- The length of the material for inspection is less than 1.5 m. The requirements for batch inspection: the inspection length should be less than 3 if the material is used in 20000 ㎡ public buildings, residential, commercial buildings with the same construction, same production manufacturer and same process construction and less than 6 if the area is more than 20000 ㎡ .

- Q: The thermal insulation hardware cloth and the Mesh, which is better?

- The thermal insulation Mesh of the wall is good. The function of the mesh and steel (iron) screen role is to prevent cracking outside the insulation board. The common Mesh is convenient to build and with a light weight and cheap prece. It does not need to be nailed but directly use the glue. The construction speed of it is fast and sometimes the bonding is not very good so that they break away from totally.

Send your message to us

Wholesale Fiberglass Mesh Plaster Reinforcement - Glass Fiber Mesh

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords