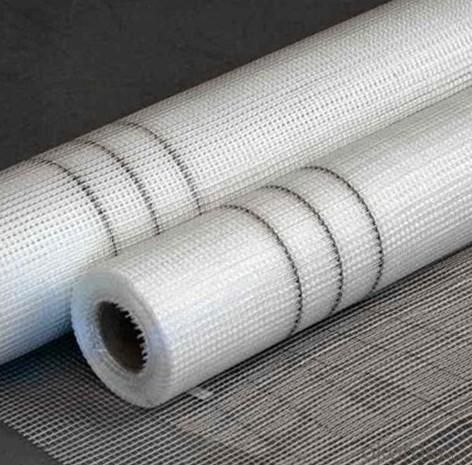

Fiberglass Mesh Rolls 145g Cloth

- Loading Port:

- SHANGHAI Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1X20GP m²

- Supply Capability:

- 1*40HQ Per Day m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Fiberglass Mesh/Fiberglass fabric/ Fiberglass screen mesh/ Fiber mesh cloth

Fiberglass mesh is mainly alkali-resistant fiberglass fabric, it use the C /E-glass fiber yarn (main ingredient is a silicate, good chemical stability) through a special weaving technique, then by the anti-alkali and reinforcing agent etc high temperature heat finishing treatments. It's an ideal engineering material in construction and decoration industry.Mesh size: 5mm x 5mm, 4mm x 4mm, or 4mm x 5mm

Weight/m2: 145g/m2

Length/roll: 50m-100m

Width: 1m

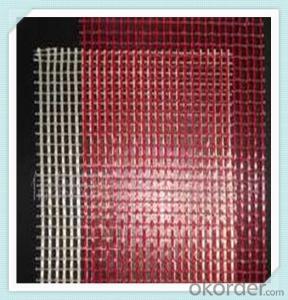

Color: white, blue, orange or other colors

Special spec can be ordered and produced by the requirements of customers

Usage/Applications of Fiberglass Mesh/Fiberglass fabric/ Fiberglass screen mesh/ Fiber mesh cloth

145g/m2 mesh fabric used in the wall and be mixed in various materials (such as brick, light wood, prefabricated structures), to prevent cracking and scatter the whole surface pressure, especially in the external wall insulation system (EIFS ).

Packaging & Delivery of Fiberglass Mesh/Fiberglass fabric/ Fiberglass screen mesh/ Fiber mesh cloth

Packaging: Each roll is shrink-wrapped, or to be packed in plastic bag. Then rolls are put into pallets and cartons.Delivery: About 25 days after confirming the order.

Characteristics of Fiberglass Mesh/Fiberglass fabric/ Fiberglass screen mesh/ Fiber mesh cloth

1. Good chemical stability: Alkali-resistant, acid-resistant, waterproof, cement erosion-resistant, and other chemicals' corrosion resistant; and strong resin bonding, soluble in styrene.

2. Outstanding craftsmanship include coating enough alkali-resist glue, our coating glue is produced by Germany BASF which can keep 60-80% strength after test in Naoh 28days later, so that guarantee high strength, high tensility, light weight.

3. Our fiberglass yarn is supplied by Jushi Group which is the largest producer of fiberglass yarn in the world like Saint Gobain, it's 20% extra strong strength and beauty surface than normal fiberglass yarn.

4. Strength retention rate> 90%, elongation <1%, the durability of more than 50 years.

5. Good dimensional stability, stiffness, smoothness an difficult to shrink and deformation, good positioning property.

6. Good impact resistance and not easy to be teared.

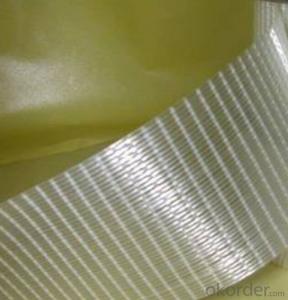

- Q: Mesh cloth tape, that is, fiberglass self-adhesive tape, how to use?

- Glass fiber mesh cloth with alkali resistant fiberglass mesh, it uses alkali free glass fiber yarn (the main ingredient is silicate, good chemical stability) by structure leno weaving and special organization, after the anti alkali, heat setting treatment such as reinforcing agent.

- Q: What standard of CE certification should be done for fiberglass mesh fabric?

- Fiberglass mesh exports to the EU must provide CE certification, generally carried out in accordance with the CPR directive.

- Q: Does the new house wall need to paste mesh?

- Pasting mesh is based on your walls, if the wall cracking too much, it is recommendated to paste mesh in the whole wall; if it is less, you just need to paste at the cracking place.

- Q: The difference between cast glass filter screen and ceramic filter screen

- Glass fiber filters to capture excess paint from the paint spraying system, avoid paint stain on the device to prevent damage to the paint surface and protect the environment. The filter room paint particles and reduce exhaust pollution, glass fiber filter is generally applicable to dry coating paint room, dry car, furniture, mechanical parts and paint system the workshop paint mist filter or kitchen fume filter.

- Q: How to layout alkali resistant glass fiber grid cloth?

- When seeting walls, gridding cloth can be cut along with the the dividing joint. Reason: the gridding cloth is used for crack resistance and the dividing joint can help reduce wall stress, therefore, it can be a way to reduce crack. Cutting is ok as long as the cardinal plane of base is not affected.

- Q: The characteristics of glass fiber mesh cloth

- High strength, high modulus, light weight.

- Q: Fiberglass mesh reinforced waterproof roll is via the texture of the tire to distinguish the waterproof quality. General polyester tire is better than fiberglass tire in quality.

- PE polyethylene film, varieties The coiled material uses two sub tread mark?number: glass fiber felt or polyester felt. The nominal weight of coiled material... What kind of SBS shoule be taken?

- Q: What is fiberglass?!

- Raw materials and their applications, glass fiber than organic fibers, high temperature resistance, non burning, corrosion resistance, heat insulation, sound insulation (especially glass cotton), high tensile strength, good electrical insulation (such as alkali glass fiber).

- Q: Which is of the mesh for the lightweight wall, one layer or two layer? The decoration of modern second-hand housing.

- It is generally to paste the one layer mesh. And the steel mesh is used between the new wall and the old wall to prevent cracking.

- Q: Fiberglass mesh is poor in sizing and softness. The generally used glue is acrylic?acid emulsion. For better sizing, what auxiliary material should be added? Soft

- Use emulsion but not urinary glue. Mesh coated with urinary glue is brittle.

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 2002 |

| Annual Output Value | Below US$1 Million |

| Main Markets | North America; South America; Eastern Europe; Southeast Asia; Africa; Oceania; Mid East; Eastern Asia; Western Europe; Central America; Northern Europe; Southern Europe; South Asia |

| Company Certifications | ISO 9001:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao Port |

| Export Percentage | 81% - 90% |

| No.of Employees in Trade Department | Above 10 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 10,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | High; Average |

Send your message to us

Fiberglass Mesh Rolls 145g Cloth

- Loading Port:

- SHANGHAI Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1X20GP m²

- Supply Capability:

- 1*40HQ Per Day m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords