Fiberglass Woven

Fiberglass Woven Related Searches

Woven Fibreglass Fiberglass Woven Fabric Fiberglass Yarn Fiberglass Fabric Fiberglass Roving Fibreglass Fabric Fiberglass Thermal Insulation Car Fiberglass Fibreglass Wool Insulation Chopped Fiberglass Fiberglass Resin Fiberglass Woven Roving Combo Mat Fiberglass Roof Philippines Fibreglass Resin Fiberglass Cloth Roll Fiberglass Wall Insulation Resin Fiberglass Fiberglass Drywall Direct Roving Fiberglass Fibreglass Pipes Fiberglass Patio Roof Roll Of Fiberglass Cloth Fiberglass French Doors Fiberglass Properties Fibreglass Mesh Tape Fiberglass Filament Winding Machine S Glass Fiberglass Owens Corning Fiberglass Roving Fiberglass Cloth Philippines Fiberglass Blanket InsulationFiberglass Woven Supplier & Manufacturer from China

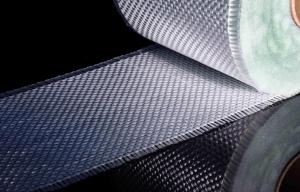

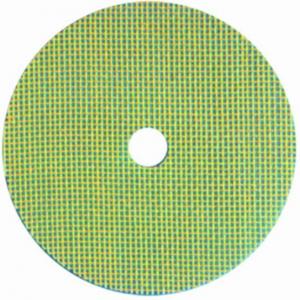

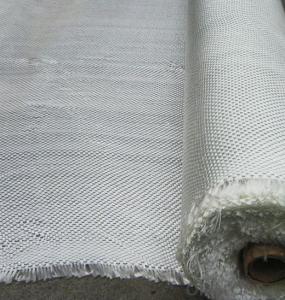

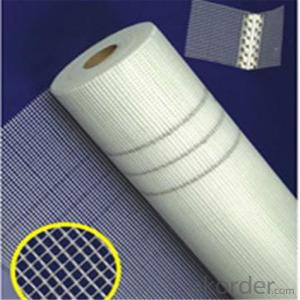

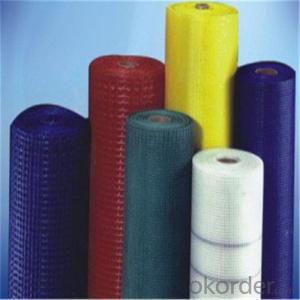

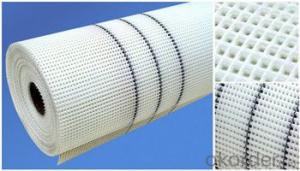

Fiberglass woven is a versatile material that encompasses a range of products such as fabrics, mats, and tapes. These products are made from glass fibers that are woven together to create a strong and durable fabric. The unique composition of fiberglass woven products makes them suitable for various applications, including insulation, reinforcement, and filtration.Fiberglass woven products are widely used in construction, automotive, and aerospace industries due to their high strength-to-weight ratio, resistance to corrosion, and ability to withstand high temperatures. They are often employed in applications where lightweight, yet strong materials are required, such as in the manufacturing of boats, wind turbines, and other industrial equipment. Additionally, fiberglass woven materials are used in the production of protective gear, electrical insulation, and as a reinforcement in composite materials.

Okorder.com is a reputable wholesale supplier of fiberglass woven products, offering a vast inventory to cater to the diverse needs of various industries. With a commitment to quality and customer satisfaction, Okorder.com ensures that the products they supply meet the highest standards and are available at competitive prices. This makes them an ideal choice for businesses looking to source fiberglass woven materials for their projects.

Hot Products