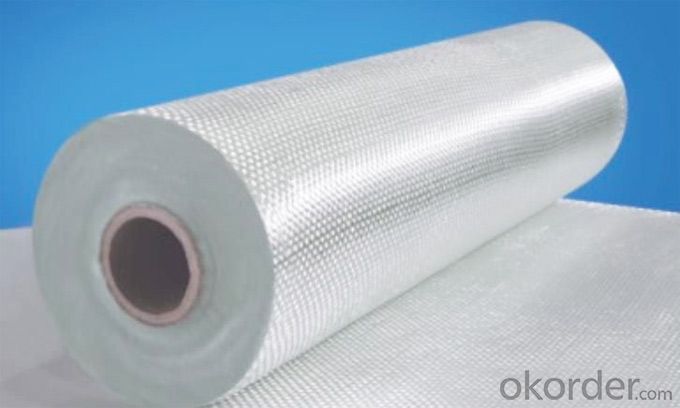

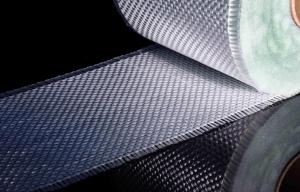

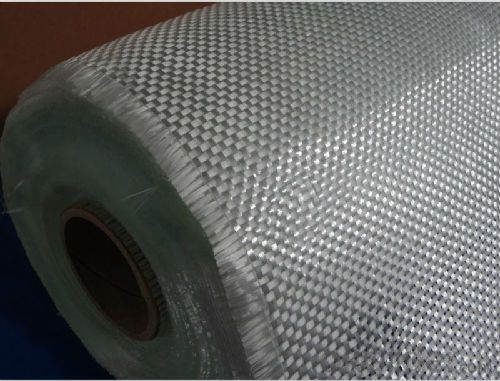

Fiberglass Glass Fiber Woven Roving

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10Ton kg

- Supply Capability:

- 100TON PER MONTH kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Woven roving is a bidirectional fabric made by roving in plian weave pattern. The construction impants to the fabric an excellent dimensional stability during handling. Woven roving is a high-performance reinforcement and widely used in hand and machine procuction, such as boats,vessels,planes and automotive parts,furniture and sports facilities,and other fields

| Item | Warp Density Ends/cm | Weft Density Ends/cm | Weight G/m2 |

| EWR270 | 46 | 41 | 270±14 |

| EWR300 | 32 | 18 | 300±15 |

| EWR360 | 32 | 18 | 360±18 |

| EWR400 | 23 | 22 | 405±20 |

| EWR500A | 22 | 20 | 504±25 |

| EWR500 | 20 | 16 | 520±26 |

| EWR580 | 26 | 22 | 580±29 |

| EWR600B | 20 | 16 | 620±31 |

| EWR600C | 28 | 20 | 600±30 |

| EWR600D | 20 | 20 | 610±31 |

| EWR800B | 20*2 | 16*2 | 850±43 |

| EWR800C | 28 | 20 | 840±42 |

| EWR800D | 20*2 | 12*2 | 847±42 |

| EWR800 | 20*2 | 15*2 | 840±42 |

Applications

1.Elementary material of FRP with anticorrosion and insulation.

2.Fireproofing and waterproof use.

3.Mainly applied in the production of boats, fiberglass pipes, containers and sports equipment

4.Applied in the automobile parts, furniture, fiberglass reinforced plastic product, etc.

Features

1.Warp and weft rovings aligned in a parallel, flat manner and uniform tension

2.Densely aligned fibers, providing high dimensional stability and easy handing

3.Good moldabllity, fast and complete resin wet-out, enabling high productivity

4.Good transparency and high strength of the composite products

Packaging & Delivery

Packaging Detail:carton+pallet

Delivery Detail:acording to customer's request

- Q: What is the function of adding fiber material to concrete ?

- In projects, some fiber materials such as paper, hemp fiber and straw are added to concrete. If plastering mortar is added into mixer, it can play the role of skeleton, improve the crack resistance and tensile strength of the plaster layer and enhance the flexibility of floated coat and durability in order to reduce floated coat contraction and make it not easy to fall. The characteristics of the fiber material will be introduced as follows: firstly, paper reinforcement includes dry and wet paper. Dry paper is use at the time of adding quick lime, It was tore up, was removed dust and soaked with water, and then 100 kg lime and 2.75 kg paper are mixed. When using, it should be made into powder by a small steel mill and 3 mm aperture sieve filter. When wet paper reinforcement (commonly known as pulp) was used, each 100 kg lime should be added into 2.9 kg wet paper reinforcement. Specific operation method is the same as that of dry paper. Secondly, the use of hemp fiber requires tenacity and purities. To make is loose, it need to be dried, linen and then it is cut into 20 mm to 30 mm. Each 100kg lime adds 1kg loose hemp which is hemp fiber grey. Thirdly, grass stalks are usually cut into rice straw or wheat straw which is no more than 30 mm long. It could be used after half a month after soaked in lime water. It also can be used as paper after soaked in lime or caustic soda. Fourthly, synthetic fiber mainly includes polypropylene fiber and nylon fiber used for mortar. When using, you should pay attention to its disparity and alkali resistance. These are the all material fiber used in concrete. You should be familiar with the characteristics of the material in order to make better use of it.

- Q: The characteristics and application of KH560

- Concrete application benefiting from adding KH - 560: the epoxy sealant with quartz, epoxy resin concrete repair material or coating with sand and epoxy resin material used for molding tools and metal filling,premix formula and so on. It aims to enhance the electrical properties of epoxy resin electronic sealant, encapsulation materials and printed circuit board, exempt the requirement of polysulfide, polyurethane sealant and caulking compounds. It benefits from specific application of the addition of KH-560. After the adjustment period. Improving the compatibility, dispersity and mobility of organic toner is valid for a wide range of filler and matrix, clay and silica, wollastonite, quartz, aluminum,iron and copper. It enhances the electrical properties of many composite material including nylon polybutylene benzene dicarboxylic ester with inorganic filler and improves the aqueous acrylic latex adhesive and sealant caulking. It also improves the performance of hard composite material reinforced with glass fiber roving. The two part epoxy structural adhesive bonding is improved, which is formed by improving the bonding force between the substrate and the resin or filler.

- Q: How to make the lining of tank acid-proof and anticorrosion.

- If it is metal can, cleaning, descaling and brushing anticorrosion lacquer will be fine.

- Q: What's the difference between g;ass reinforeced plastics and ordinary glass?

- There are no difference and there are all glass fiber reinforced plastic!

- Q: Situation of nonwoven materials.

- A fiber as main ingredient in nonwoven adhesive bonded materials. Needle punched nonwoven materials, Spunlaced Nonwovens Materials, spunlaid nonwovens method, fiber mesh constitute the main body of nonwoven materials, fiber in Nonwovens in these accounted for more than half or even one hundred percent. Fiber as a component of nonwovens fiber tangles in acupuncture Nonwovens Materials, Spunlaced Nonwovens Material and no yarn stitch bonding nonwoven material, part of fiber like buddle structure and coil web fibers to reinforce the fiber web. Three, fiber as the adhesive components of Nonwovens in most thermal bonded nonwovens, hot melt fiber into web in thermal bonding when all or part of melting, forming a hot melt adhesive composition in Web reinforcement.

- Q: Formula of glass fiber yarn

- It is usually known as the short fiber. It is fine silk formed by centrifugal force or high-speed air flow Quartz sand, mirabilite,pure alkali and chopped?strand. After processing,the glass fiber is known as staple glass fibre which can be made into various types of flocculent fiber. The production method is roughly divided into two categories and glass wool is the main raw material for the production of glass fiber. Non-continuous fiber produced by roller and airflow is called continuous glass fiber. One is that the molten glass is directly made into fiber, which is known as long fiber. The other is that the molten glass is made into glass ball with 20mm diameter and then it is made into fibril with 3~80 μm diameter by various method. Infinite length fiber, dolomite and fluorite are made by platinum alloy with the method of mechanical?wiredrawing.

- Q: What can alkali free glass fiber and alkali resistant glass fiber do

- According to the order of reinforced material combination, the fabric surface is sheetlike, by using RTM method: The area and mass along the width direction is uniform. Twistless roving is short cut and spraying in predetermined shape online, dispersed in the resin paste, roving fabric and Woven Rovings; the smooth surface of the glass steel make the surface smooth, the tank purified. Short fiber needle felt is cut into 50mm glass fiber roving. Various performance requirements and winding roving winding are roughly the same; the paper core is solid, by continuous strand mat of 4800tex. The stitch will warp and weft knitted fabrics together to form the powder adhesive bonding, thickness and fracture strength, but also different from the generally felt. Yarn density is uniform; The roving tension is uniform. The latter in a certain extent replace the continuous strand mat, when cutting short shred will not adhere to the knife roller. Pultrusion roving can be combined by multiple strand direct roving. Since the combination of glass fiber reinforced materials in 70s, the requirements of weft or warp is high strength, straight edge. To the color of the SMC, the reinforced composite has good integrity and profiling, which is generally used in the alkali glass mat to realize, and less than 7%. Usually SMC roving is generally 2400tex. Width and length are consistent with the standard. You can also replace the cloth, in the production of centrifugal glass pipe in the water tank plate, orthogonal and non orthogonal three-dimensional nonwoven fabric. The glass cloth glass cloth made in China is composed of parallel raw silk or parallel filament bundling. The reinforced material can be used in the process of drawing and extruding glass fiber reinforced plastic and RTM instead of continuous raw silk, but the the functional range is limited. Mainly used in the pultrusion method.

- Q: how to produce glass?reinforced?plastics grating

- It is formed by glass fiber after extrusion.

1. Manufacturer Overview

| Location | Zhejiang, China |

| Year Established | 1969 |

| Annual Output Value | Above US$ 150 Million |

| Main Markets | overseas companies in Hongkong, Canada, South Africa, South Korea, India, Italy, Singapore, France and many other countries and regions. |

| Company Certifications | ISO9001;ISO14001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 40%-50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English |

| b) Factory Information | |

| Factory Size: | Above 5000,000 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | |

| Product Price Range | Average |

Send your message to us

Fiberglass Glass Fiber Woven Roving

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10Ton kg

- Supply Capability:

- 100TON PER MONTH kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords