E-Glass Fiber Assembled Roving for Chop 162

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 19320 kg

- Supply Capability:

- 5000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of E-Glass Fiber Assembled Roving for Chop

E-glass fiber chop roving is mainly designed as a reinforcement for GRP pipes. It is treated with a special silane-based siz and compatible with UP and vinyl ester resins. The product offers strong resin adsorbability and the end products have strong water resistance and excellent chemical resistance. The roving is typically used to make GRP pipes.

Specification of E-Glass Fiber Assembled Roving for Chop :

PRODUCT NAME | E-GLASS FIBER ASSEMBLED ROVING for SPRAY UP 2400TEX | |

TEST ITEM | STANDARD NO. | STANDARD VALUE |

LINEAR DENSITY(TEX) | ISO 1889-1997 | 2400±120 |

STIFFNESS (MM) | iso 3375-1997 | 135±15 |

COMBUSTIBLE MATTER CONTENT (%) | iso 1887-1995 | 1±0.15 |

moisture CONTENT (%) | iso 3344-1997 | ≤0.15 |

Product Properties of E-Glass Fiber Assembled Roving for Chop:

1. Excellent process: easily chopped, good dispersion flay lying down and good anti-static performance.

2. Good wet-out: quick wet-out (resin), easily delete bubbles, well compatible with different resins.

3. Good composite performance: the composite is with properties of high mechanical strength and high transmittance etc.

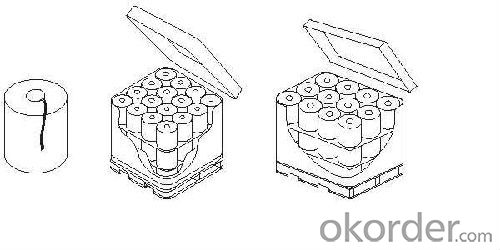

Package of E-Glass Fiber Assembled Roving for Chop:

The roving to be packed on 20 pallets for a 20' container. The detailed package is listed as follows,

4 X 4 rolls/layer, 4 layer/pallet, 10 pallets

4 X 4 rolls/layer, 3 layer/pallet, 10 pallets.

Each layer is seperated with paperboard.Each pallet is supported by very strong papercoil at the four corners of pallet, then packed in big carton, wrapped in a polythene stretched film. The roving on pallet after package is visible.

Storage of E-Glass Fiber Assembled Roving for Chop:

Unless otherwise specified, fiberglass products should be stored in a dry, cool and rain-proof area. It is recommended that the room temperature and humidity should be always maintained at 15℃-35℃ and 35%-65% respecitively. To ensure safety and avoid damage to the product, the pallets should not be stacked more than three layers high. When the pallets are stacked in 2 or 3 layers, care should be taken to correctly and smoothly move the top pallet.

FAQ

1. Why Choose us?

CNBM is a stated owned company, provide the guarantee for the best quality, best service and safety business.

2. How will we guarantee the quality?

a, ISO 9001-2008 quality control system;

b, Strict and regular quality control in production;

c, Inspeciation when loading into container before shippment;

d, Sample stock for one year for quality tracing and record.

3. What is your MOQ?

Our MOQ is one pallet.

4. Can you provide sample?

Yes, samples are in stock. we can offer free sample for you.

5. Payment terms?

We can accept L/C, T/T etc.

6. Main Characteristics?

Fast wet-out, good dispersion performance, high split ratio;

And the size and specification can be produced and design according to your demand.

7. What is the Production Lead Time?

20*20GP each day.

- Q: How to make a glass fiber reinforced plastic?

- The answer is no. The glass fiber reinforced plastic grille can be made with a mold, so it would be very easy to do it, while by manual, it would be troublesome, and do not have compressive property.

- Q: An introduction to glass fiber window?screening

- It is made of glass fiber and PVC. The weave and process uses glass fiber monofilament plastic coated process and is formed by weaving, heating and shaping.

- Q: What is the difference between pultrusion geogrids and molding geogrids.

- on many occasions. For example, glass?reinforced?plastics grating in carwash is generally used for holder or stand. Molded glass?reinforced?plastics grating is usually used for walkways, platforms, tree grate fence and so on. It is widely used in sewage treatment plants waste board and residential parking lot.

- Q: What's the difference between g;ass reinforeced plastics and ordinary glass?

- Yes, P is a glass steel! The difference is that there are some differences between the materials of the antenna structure and the common vertical antenna, but the principle is the same.

- Q: Medium alkali glass fiber cloth

- It is mainly used for large and medium sized non-metal container, equipment, pipe and shell.

- Q: What type of cement is used in the common GRC component?

- Fiber: You can selectively add some of the volcanic ash active material: High efficiency water reducing agent can be selectively added to the water: The basic composition of GRC material is cement: when the product contains steel reinforcement or steel embedded parts of.5%, the low alkalinity sulphoaluminate cement. The acrylate copolymer emulsion, antirust agent and other additives, fiber and water and other additives to improve the performance of the materials later. European and American countries require the use of GRC in the glass fiber zirconia content should be not less than 16, antifreeze, early strength agent, retarder, white Portland cement. . Additive is conducive to improve the integrated performance of GRC products, including the alkali resistant glass fiber twistless roving. Polymer. Other materials: Usually the added polymer is emulsion C, and alkali resistant glass fiber mesh. The fibre in the GRC material must be of alkali resistant glass fiber: Usually the cement used in GRC material are mainly rapid hardening sulphoaluminate cement and Portland cement. Cement. More details to be continued. GRC material is made of sand, alkali resistant glass fiber chopped yarn. It is durability and shall not use calcium chloride additives. . , for example, strength, anti permeability,

- Q: What is the difference between the glass and glass?reinforced?plastics?

- Glass and glass?reinforced?plastics is totally different two things.Generally speaking, glass?reinforced?plastics is a kind of plastics with cloth or felt made by glass fiber as reinforced plastics.

- Q: Production process of glass fiber reinforced plastic

- Simple glass reinforced plastics are melted together again

- Q: What is the difference glass fiber roving and fine yarn ? Does the equipment used for production have any difference.

- 6 microns non-alkali, 9 micron twistless roving (bulk yarn), 80 alkali , 30 twist roving ans 21 medium alkali. It is a glass fiber integrated production enterprises combined management, scientific research and development. The company has advanced production equipment and strong technical force. Main production includes 30 alkali-free glass fiber yarn and 40 fine yarn with annual production of 1500 tons.

- Q: How to deal with the folding force of glass fiber plastic coated yarn.

- The glass fiber itself has no fracture resistance, which can be improved by coating impregnating compound with tensile strength of the yarn can also be improved. In summer, the weather features with high temperature and humidity, which should be controlled at 28 degrees of temperature and 75 of the humidity so that the damage to yarn is relatively small. You may consider to improve the toughness of the coating material.

1. Manufacturer Overview

| Location | Chongqing, China |

| Year Established | 1971 |

| Annual Output Value | Above US$ 50 Million |

| Main Markets | North America, Eastern Europe, Southeast Asia, Mid East, Eastern Asia |

| Company Certifications | ISO9001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Chongqing |

| Export Percentage | 40%-50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English |

| b) Factory Information | |

| Factory Size: | Above 2000,000 square meters |

| No. of Production Lines | Above 4 |

| Contract Manufacturing | |

| Product Price Range | Average |

Send your message to us

E-Glass Fiber Assembled Roving for Chop 162

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 19320 kg

- Supply Capability:

- 5000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords