All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

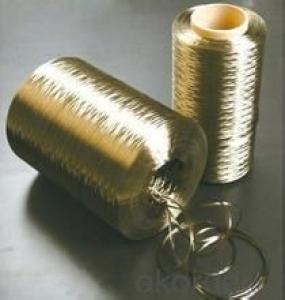

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Fiberglass Chopped StrandView More

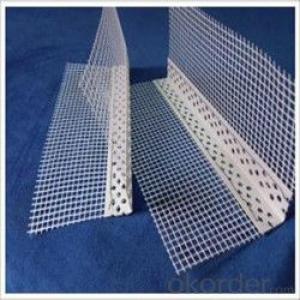

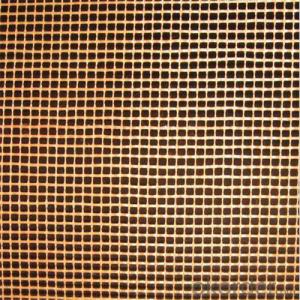

Fiberglass Mesh ClothView More

Composite PipesView More

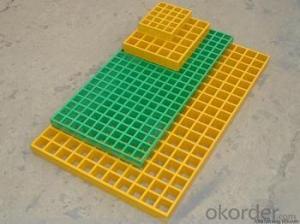

FRP Pultrusion ProfilesView More

Fiberglass Mat TissueView More

Fiberglass FabricsView More

Fiberglass MeshView More

Composite TankView More

Fiberglass Mesh tapeView More

PolymerView More

FRP Roofing PanelView More

Fiberglass RovingView More

Q & A

What are the different fiberglass reinforcement options for panels?

There are several different fiberglass reinforcement options for panels, including woven fiberglass cloth, chopped strand mat (CSM), and fiberglass roving. Woven fiberglass cloth is a popular choice as it offers excellent strength and flexibility. CSM, on the other hand, consists of randomly oriented short strands of fiberglass and is commonly used for its ease of moldability. Fiberglass roving, which is made up of continuous strands of fiberglass, provides high tensile strength and is often used in applications that require additional reinforcement.

What is the fiberglass manufacturing process?

The fiberglass manufacturing process involves several steps, starting with the production of glass fibers. Glass is melted at high temperatures and then forced through small openings to create fine strands of fiber. These fibers are then treated with various chemicals to enhance their strength and durability. Next, the fibers are woven or layered together to form a mat or fabric. The mat is then impregnated with a resin, usually made of polyester or epoxy, which hardens and binds the fibers together. The resulting material is then cut, shaped, and cured to create various fiberglass products, such as insulation, boats, automotive parts, and building materials.

How do you determine the right fiberglass reinforcement for a specific project?

To determine the right fiberglass reinforcement for a specific project, several factors need to be considered. Firstly, the type of project and its requirements should be analyzed. Consider the desired strength, flexibility, and durability needed for the project. Next, evaluate the environmental conditions the fiberglass will be exposed to, such as temperature, moisture, and chemicals. Additionally, the manufacturing process, budget, and any regulatory standards should be taken into account. Consulting with experts in the field or conducting thorough research on different types of fiberglass reinforcements can provide valuable insights and help make an informed decision. Ultimately, the right fiberglass reinforcement should meet the project's specific needs while considering its unique circumstances.

What are the different resin systems used with fiberglass?

There are several different resin systems used with fiberglass, including polyester, epoxy, and vinylester. Each resin system has its own unique properties and characteristics, making them suitable for different applications and environments. Polyester resin is commonly used for general-purpose fiberglass applications, while epoxy resin offers superior strength and durability, making it ideal for high-performance and structural applications. Vinylester resin combines the best properties of polyester and epoxy resins, providing good strength, chemical resistance, and impact resistance. Ultimately, the choice of resin system depends on the specific requirements of the project or application.

Can fiberglass be made fire-retardant?

Yes, fiberglass can be made fire-retardant by treating it with various chemical additives or coatings that help reduce its flammability and slow down the spread of fire.

Wholesale Fiberglass Supply from supplier in Morocco

Whether you are in the construction, industrial, or manufacturing sector, our Fiberglass Supply products are designed to meet the highest quality standards and cater to your specific needs. We offer a wide range of fiberglass materials, including fiberglass insulation, fiberglass reinforced panels, fiberglass pipes, and fiberglass fabrics.

Our team of experts is dedicated to providing excellent customer service and technical support throughout the entire procurement process. From product selection to order placement and delivery, we ensure a seamless experience for our customers. Our knowledgeable staff can assist you in selecting the right Fiberglass Supply products for your project, providing you with accurate quotations and timely delivery.

As a subsidiary platform of CNBM, one of the largest building materials companies in the world, we have access to a vast network of suppliers and manufacturers, ensuring competitive pricing and a wide selection of Fiberglass Supply products. We continuously strive to meet and exceed customer expectations, offering reliable and efficient solutions to enhance your project's success.

Partnering with us means gaining access to a reliable and trusted supplier of Fiberglass Supply products in Morocco. Our commitment to quality, customer satisfaction, and technical expertise sets us apart in the industry. Whether you need Fiberglass Supply products for insulation, reinforcement, or any other application, we have the solutions to meet your requirements.

Contact us today to learn more about our comprehensive Fiberglass Supply products and services and how we can support your projects in Morocco. Let us be your trusted partner for all your Fiberglass Supply needs.

Our team of experts is dedicated to providing excellent customer service and technical support throughout the entire procurement process. From product selection to order placement and delivery, we ensure a seamless experience for our customers. Our knowledgeable staff can assist you in selecting the right Fiberglass Supply products for your project, providing you with accurate quotations and timely delivery.

As a subsidiary platform of CNBM, one of the largest building materials companies in the world, we have access to a vast network of suppliers and manufacturers, ensuring competitive pricing and a wide selection of Fiberglass Supply products. We continuously strive to meet and exceed customer expectations, offering reliable and efficient solutions to enhance your project's success.

Partnering with us means gaining access to a reliable and trusted supplier of Fiberglass Supply products in Morocco. Our commitment to quality, customer satisfaction, and technical expertise sets us apart in the industry. Whether you need Fiberglass Supply products for insulation, reinforcement, or any other application, we have the solutions to meet your requirements.

Contact us today to learn more about our comprehensive Fiberglass Supply products and services and how we can support your projects in Morocco. Let us be your trusted partner for all your Fiberglass Supply needs.

Hot Search

- Fiberglass Chopped Strand in Cameroon

- Fiberglass Mesh Cloth in Slovenia

- Composite Pipes in Honduras

- FRP Pultrusion Profiles in Kazakhstan

- Fiberglass Mat Tissue in Switzerland

- Fiberglass Fabrics in Mexico

- Fiberglass Mesh in Monaco

- Composite Tank in Poland

- Fiberglass Mesh tape in Bolivia

- Polymer in Palestine