Roving Mat Fiberglass E-Glass Assembled Roving for Spray Up 180

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 19600 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of E-Glass Fiber Spray Up Roving

10C Assembled roving for SPRAY UP process which is coated with high performance silane sizing, compatible with UP resin and Vinyl ester resin.

It is a versatile purpose spray up roving used to fabricate boats, bathtubs, water tanks, centrifugal casting pipes and panel etc.

Specification of E-Glass Fiber Spray Up Roving

PRODUCT NAME | E-GLASS FIBER ASSEMBLED ROVING for spray up 2400TEX | |

TEST ITEM | STANDARD NO. | STANDARD VALUE |

LINEAR DENSITY(TEX) | ISO 1889-1997 | 2400±120 |

STIFFNESS (MM) | iso 3375-1997 | 130±15 |

COMBUSTIBLE MATTER CONTENT (%) | iso 1887-1995 | 1.15±0.15 |

moisture CONTENT (%) | iso 3344-1997 | ≤0.10 |

Product Properties of E-Glass Fiber Spray Up Roving

1. Excellent process: easily chopped, good dispersion flay lying down and good anti-static performance.

2. Good wet-out: quick wet-out (resin), easily delete bubbles, well compatible with different resins.

3. Good composite performance: the composite is with properties of high mechanical strength and good surface effect etc.

Package of E-Glass Fiber Spray Up Roving

The roving will be packed on 20 pallets for a 20ft' container, or can be packed in small carton box.

The detailed package is listed as follows,

4 x 4 rolls/layer, 4 layer/pallet, 10 pallets

4 x 4 rolls/layer, 3 layer/pallet, 10 pallets.

Each layer is separated with paperboard. Each Pallet is supported by very strong paper tube at the four corners of pallet, packed in big carton, wrapped in a polythene stretched film.

.

Storage of E-Glass Fiber Spray Up Roving

Unless otherwise specified, fiberglass products should be stored in a dry, cool and rain-proof area. It is recommended that the room temperature and humidity should be always maintained at 15℃-35℃ and 35%-65% respecitively. To ensure safety and avoid damage to the product, the pallets should not be stacked more than three layers high. When the pallets are stacked in 2 or 3 layers, care should be taken to correctly and smoothly move the top pallet.

FAQ for E Glass Spray up Roving

1. Why Choose us?

CNBM is a stated own company, provide the guarantee for the best quality, best service and safety business.

2. How will we guarantee the quality?

a, ISO 9001-2008 quality control system;

b, Strict and regular quality control in production;

c, Inspeciation when loading into container before shippment;

d, Sample stock for one year for quality tracing and record.

3. What is your MOQ?

Our MOQ is one pallet.

4. Can you provide sample?

Yes, samples are in stock. we can offer free sample for you.

5. Payment terms?

We can accept L/C, T/T etc.

6. What is the Production Lead Time?

5 *20GP each day.

- Q: What are the main molding processing methods of plastics

- There are many methods of plastic forming. Six main forming methods are listed below: 1 injection molding and injection molding, extrusion molding. 2. extrusion molding, which is the main molding of thermoplastic plastic molding, 3 hollow blow molding, also known as the 4 compression molding also called compression molding. The upper and lower mold installation the template in the press on, the plastic material directly into the cavity, the mold is closed, full of plastic cavity in the heat and pressure, setting after plastic products. 5, injection molding and transfer molding. One of the main forming method is thermosetting plastics. It is feeding room, plastic pellets into mould in the heating, melting plastic under pressure through the pouring system of bottom mold transfer chamber fills the cavity, and then cure it. 6, solid molding molding plastics in melting temperature, in the molding process No obvious flow condition, for two times molding plastic sheet, such as vacuum molding, compression molding and air pressure molding, original for thin-walled parts molding, first used in the manufacture of thick wall parts. 7, other molding calendering, there are many casting plastic molding methods...

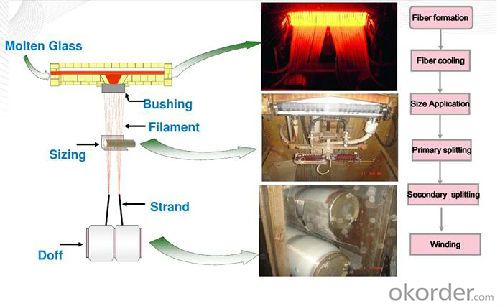

- Q: What is the technological process of glass?Fiber?chopped?strand mat?

- Fiber reinforced epoxy resin composite material forming process. Compared with traditional materials, the composite material has a series of irreplaceable characteristics, which has been developed rapidly since the second world war. Although the production is small, but the level of composite materials is one of signs that marks national or regional science, technology and economic level. Composite material is mainly composed of two parts: reinforced material and base material. Reinforced material: In composite material, some reinforced material such as the glass fiber in glass?reinforced?plastics and carbon fiber in CFRP(carbon fiber reinforced material) give major mechanical property to composite material. Matrix: Matrix is a single material which aims to make composite material as a whole such as resin in glass?reinforced?plastics( epoxy resin referred in this paper). Composite materialcan be divided into three kinds according to the matrix material: resin composite material, metal matrix composite material, and inorganic nonmetallic composite material such as ceramic matrix composite material.

- Q: Materials of european component

- Polymer:.5%, the low alkalinity sulphoaluminate cement, forming perfectly, do not use additives which contain calcium chloride based. 2. It is anti-permeability. As the Portland cement, it can be formed at one time. 4, China requires that when using the ordinary portland cement, the zirconia's content do not less than 16, including alkali resistant glass fiber roving, white portland cement..5%:. 3. plasticizer: The fibers used in GRC must be alkali resistant glass fiber, fiber, early strength agent, alkali resistant glass fiber mesh and retarder. As the requirement of Europe and America, the content of zirconium oxide in glass fiber should be no less than 16: The acrylic emulsion is usually the polymer: We can add some of the volcanic ash active material selectively, that is, acrylic copolymerized emulsion. 5: We can select soft rubber mold, made by high temperature resin which suit the hard outer mold: High efficiency water and anti freezing agents reducing agent can be selectively added. That is conducive to comprehensive performance, enhance the durability of GRC products commonly. The cement can be hardening at fast speed. Sulphoaluminate cement /additives, alkali resistant glass fiber chopped yarn is easy demoulding.

- Q: Introduction of inorganic glass fiber reinforced plastic air pipe

- Inorganic glass fiber reinforced plastic air pipe, according to the properties of the binding materials, can be divides into: Made of binding materials with glass fiber mesh cloth hydraulicity inorganic glass steel duct and made of cementitious materials and glass fiber mesh air hardening modified magnesium oxychloride cement duct with two types of modified magnesium oxychloride cement to the sulfate type. The pH value of the hardened material should be less than 8.8, and there is no alkalinity corrosion of the glass fiber. Inorganic glass steel duct should be used alkali-free, medium alkali or alkali resistant glass fiber mesh cloth, and are consistent with current national standard "glass fiber grid" JC561, "the alkali free glass fiber roving," JC/T281, "in the alkali glass fiber roving" JC/T576 regulations. The quality of magnesium oxychloride cement duct Magnesium Oxide should comply with the national standard "Magnesium Oxide" light burned magnesite products with WB/T1019-2002 regulations. Inorganic glass steel duct can divided into the overall common type (non insulation), integral insulation type (inner and outer surface of inorganic glass steel, middle insulating material) and combination type (by special adhesive, composite plate, flange, reinforcement angle etc) and the combination of insulation, its production parameters should comply with the provisions of the table 1, 2, 3. The longitudinal and transverse lap joint distance between adjacent layers of glass fiber grid cloth should be more than 300mm, and the distance of the same layer lap joint shall not be less than 500mm. Lap length should be greater than 50mm. The wind pipe surface thickness of the slurry flating glass fiber mesh cloth is appropriate. And the surface do not have dense pores and spillage.

- Q: Carbon fiber is better than glass fiber reinforced plastic

- Carbon fiber has many excellent properties, carbon fiber axial strength and high modulus, low density, high performance, no creep, non oxidation under the environment of high temperature resistance, good fatigue resistance, between heat and electrical conductivity between the metal and non metal, smaller thermal expansion coefficient and anisotropy, good corrosion resistance, X Radiability good. Good conductivity, thermal conductivity, good electromagnetic shielding, etc..

- Q: Main characteristics of glass?reinforced?plastics grating

- long period of installation and use, aging resistance, free maintenance and so on. llightweight, glass fiber content of more than 30% (weight percent), beautiful. Glass?reinforced?plastics grating is based on unsaturated polyester resin (includes isophthalic,ethylene, phenolic aldehyde, bisphenol A) and is made up of glass fiber roving( wind or pultrusion, middle-alkali or non-alkali). It is formed by weave and mould pressing in metal mould or by heating after hand lay-up with impact resistance, steadiness, skid?resistance, anticorrosion, fire?retardant and weather resistance. Moreover, this product with insulation and thermal insulation property is flat in appearance, good in quality and is easy to cut.

1. Manufacturer Overview

| Location | Chongqing, China |

| Year Established | 1971 |

| Annual Output Value | Above US$ 50 Million |

| Main Markets | North America, Eastern Europe, Southeast Asia, Mid East, Eastern Asia |

| Company Certifications | ISO9001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Chongqing |

| Export Percentage | 40%-50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English |

| b) Factory Information | |

| Factory Size: | Above 2000,000 square meters |

| No. of Production Lines | Above 4 |

| Contract Manufacturing | |

| Product Price Range | Average |

Send your message to us

Roving Mat Fiberglass E-Glass Assembled Roving for Spray Up 180

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 19600 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords