Basalt Fiber Rebar for Highway Engineering Basalt Composite Bar

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 4000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Basalt Fiber Rebar for Highway Engineering Basalt Composite Bar

Introduction

Basalt composite bar is similar to carbon fiber and fiberglass, but it has better mechanical properties and is lower in cost tah

Basalt composite bar is an ideal advanced material to replace steel and glass rebar. It can provide different size and apperance bars to meet clients demanding.Such as sand coated ,without sand-coated,rod,basalt rebar with steel core inside,which is widely used in the production of building components,in view of their high electro-insulating propertied ,basalt bars are used for making insulators for high -voltage power lines ,hydraulic engineering,concrete barriers,highlighting poles & seismic hazards.And rebar with cable in the core is new technology to supervise the condition of buildings,airports.tunnels,etc.

Property

1. Has a green environment-friendly performance

2. Alkali and radiation resistant

3. Fire-resistant and high-strength

4. Like fiberglass many products are made including yarn, mesh, geo-grid, roving, cloth, composite bar, chopped fiber, unidirectional cloth, fabrics, needled mats, Basalt Rebars, etc.

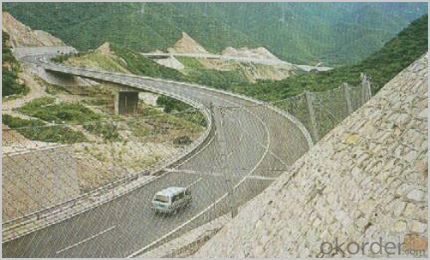

Applications

1, solve the north, south and humid areas and poor areas of acid-base environment, bridge, road corrosion resistance

of reinforced concrete structure issues, life issues;

2, solve the highway continuously reinforced concrete pavement construction technical problems and the need for welding

steel reinforced concrete structure of the problem;

3, reduce the weight of the bridge, to provide its carrying capacity and service life;

4, solution mining, tunnel, highway slope supporting the permanent anchor;

5, simplified construction difficulty, to improve construction efficiency, shorten the construction period and construction of

part of the cost savings;

6, lower construction cost and total project cost, and reduce maintenance costs.

Specification

Basalt Fiber Rebar | |||

Type | Nominal Diameter(mm) | Weight(g/m+-5%) | Coil length(m) |

BFRP-4 | 4 | 25 | 100-300 |

BFRP-6 | 6 | 56 | 100-300 |

BFRP-8 | 8 | 100 | 100-300 |

BFRP-10 | 10 | 158 | 100-300 |

BFRP-12 | 12 | 227 | 100-300 |

BFRP-16 | 16 | 405 | Piece length cut according to customer's requested |

BFRP-19 | 19 | 592 | |

BFRP-22 | 22 | 768 | |

BFRP-25 | 25 | 1076 | |

FAQ

1. How long will you get reply?

Any inquiry will be replied within 24 hours. Usually we will reply within 12 hours.

2. How long is warranty period?

We provide 3 year warranty period.

- Q:Who is going to handle the comonent joint of GRC in the exterior wall?

- Both of them should be tested. The installation process will handle it in surface flat, the rest of the process will continue.

- Q:What is glass fiber for?

- Glass fiber is a kind of excellent inorganic non-metallic materials with a great variety. It has many advantages such as good insulation, strong heat resistance, good corrosion resistance and high mechanical strength, but its disadvantage is brittle and poor wear resistance. It uses glass ball or waste glass as raw materials and is formed by high temperature melting, wire drawing, winding and weaving. The filament diameter is from several microns to over twenty micron which is equal to 1/20-1/5 of a hair with each bundle is formed by hundreds or even thousands of monofilament. Glass fiber is often used as the reinforced material in the composite material, electrical insulating materials and heat or thermal insulation materials. It is widely used in national economy field such as circuit board. Twistless roving is composed of parallel raw silk or parallel filaments. According to glass composition, twistless roving glass can be divided into good or better resin permeability. alkali free glass twistless roving and medium alkali glass twistless roving The diameter of glass fiber used in the production of glass roving is from 12 to 23 μm . The number of twistless roving is from 150 to 9600 (tex). Twistless roving can be directly used for producing some composite material with high content of glass?fiber. (6) In the preform process, twistless roving is widely used; Twistless roving has a good property of degradation and each bundle fibers is formed by hundreds or even thousands of monofilament. Twistless roving used for pultrusion can be formed by combined multiple strands or twistless roving. The diameter of glass fiber used in the production of glass roving is from 12 to 23 μm .

- Q:What is the difference between pultrusion geogrids and molding geogrids.

- Bearing profiles can moulding FRP geogrids after demoulding. The upper layer is plate structure: It is mainly formed by connecting pultrusion moulding "I" or "T". At the same time glass fiber twistless roving is spreaded in large metal mold with the lower pultrusion geogrids is hand paste. Its role is to connect the bearing profile. According to need, various extrusion molding round bar or abnormal bar interval material are used. Pultruded FRP geogrids mainly consists of three parts and then formed by curing. Pultrusion moudling "I" or "T" profile are used as a bearing rod with various pultruded round bar or abnormal bar (adhesive bar) are used as cross bar by adhesion agent. According to a certain distance, transverse rod and the bearing rod is fixedly connected together to form the FRP geogrids. The surface of molding FRP geogrids in the production can be sealed and plastic geogridsis produced by machine. Its function is to adjust and fix the void ratio of the glass fiber reinforced plastic grating.

- Q:Model parameters of glass fiber reinforced plastic and glass fiber cloth

- The materials for strengthen are Medium, vinyl type and flame retardant, vinyl resin. There are many types of materials like phthalate, benzene, alkali free glass fiber roving, knitted mat etc.: polyester resin

- Q:What is rippled glass?

- The twistless roving glass fiber and its products and materials with unsaturated polyester resin as main raw materials, is similar to sinusoidal wave form and trapezoidal cross sections.

- Q:What does the basalt fiber do?

- According to its characteristics, it is a very wide range of industrial raw materials. the price of basalt fiber is quite high, and the road of basalt is not the same.

- Q:What are the advantages of glass fiber reinforced plastic antennas? What's the difference between an ordinary antenna and an ordinary one?

- SMC and its molded products have the following characteristics: light weight, high strength, precise size, good batch quality and zero shrinkage. With a surface level, mechanization, a high degree of automation, applicable to high surface quality requirements, large output, uniform thickness of the product.

- Q:Which tensile strength of alkali resistant glass fiber mesh is bigger, the lateral one or longitudinal one?

- The horizontal one is big, but longitudinal one is small. (the horizontal one is the width direction of mesh)

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Basalt Fiber Rebar for Highway Engineering Basalt Composite Bar

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 4000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords