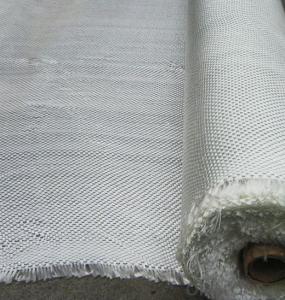

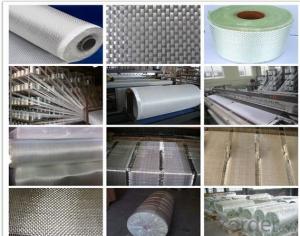

Fiberglass Woven Roving Cloth - Low Density 68 Tex G75 Yarn Roving

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Brief Introduction of Fiberglass Yarn 68 TEX (G75)

According to the final applications, yarns can be divided into 2 types, electrical yarns and industrial yarns. The diameter of electrical yarns covers a wide range from D to G, while the industrial yarns from BC to K. Based on starch or silane sizing, yarns can be divided into 2 types, Y-Yarn series and T-Yarn series.

Both Y-series and T-series piled yarns are usually designed for weaving cloth in various industrial applications.

Features of the Fiberglass Yarn 68Tex (G75)

Good tolerant control for linear density

Low Fuzz

Excellent weaving performance

Technical data or specification of Fiberglass Yarn 68Tex G75

Sizing Type | Filament Diameter (u m) | Linear Density (Tex) | Twist (T/m) | Tensile Strength (N/Tex) | Loss on Ignition (%) | Moisture Content (%) | ||

ISO1888 | ISO3374 | ISO1890 | ISO3341 | ISO1887 | ISO3344 | |||

Y/T | 9+/-1 | +/-5% | 40<=T<=120 | +/-10% | Y | >=0.4 | <=1.5 | <=0.15 |

120<=T | +/-8% | T | >=0.45 | |||||

Note: Above specifications are standard in common use, other specifications are available upon request.

Treating: Silane Treated (Non-Wax) and Wax Treated.

Packaging & Delivery of Fiberglass Yarn 68Tex

Platics core bobbin: 8 kg per bobbin, 66 bobbins per pallet. Smaller paper bobbin: 4~6kg per bobbin, 66 bobbins per cartion.

FAQ:

- Q: Does glass fiber reinforced plastic has expiration date?

- High temperature. When you store it, you need to pay attention to moisture proof and dust. Glass fiber roving has no expiration date.

- Q: What is the function of adding fiber material to concrete ?

- In projects, some fiber materials such as paper, hemp fiber and straw are added to concrete. If plastering mortar is added into mixer, it can play the role of skeleton, improve the crack resistance and tensile strength of the plaster layer and enhance the flexibility of floated coat and durability in order to reduce floated coat contraction and make it not easy to fall. The characteristics of the fiber material will be introduced as follows: firstly, paper reinforcement includes dry and wet paper. Dry paper is use at the time of adding quick lime, It was tore up, was removed dust and soaked with water, and then 100 kg lime and 2.75 kg paper are mixed. When using, it should be made into powder by a small steel mill and 3 mm aperture sieve filter. When wet paper reinforcement (commonly known as pulp) was used, each 100 kg lime should be added into 2.9 kg wet paper reinforcement. Specific operation method is the same as that of dry paper. Secondly, the use of hemp fiber requires tenacity and purities. To make is loose, it need to be dried, linen and then it is cut into 20 mm to 30 mm. Each 100kg lime adds 1kg loose hemp which is hemp fiber grey. Thirdly, grass stalks are usually cut into rice straw or wheat straw which is no more than 30 mm long. It could be used after half a month after soaked in lime water. It also can be used as paper after soaked in lime or caustic soda. Fourthly, synthetic fiber mainly includes polypropylene fiber and nylon fiber used for mortar. When using, you should pay attention to its disparity and alkali resistance. These are the all material fiber used in concrete. You should be familiar with the characteristics of the material in order to make better use of it.

- Q: Glaglass?reinforced?plastics doors and windows and broken aluminum alloy door and windows, which one is more practical?

- The price of the genuine broken aluminum alloy is higher than that of glass?reinforced?plastics. The principle of broken bridge aluminum alloy window is to use PA66 nylon to make indoor and outdoor two layer aluminum alloy separate but also connect into a whole. 2: The current market price, after the expansion and contraction and constant insulation material, needs to be tested. 3. At present, the domestic low-ends turn PA66 into the plastic insulation strip, so that the window itself should not be counted as energy-saving window, then cured by heating ans uses unsaturated resin as subtrate material. They all use the same hollow glass and the aluminum alloy itself is heat conductive material, thus glass steel window is more effective to reduce the heating conduction through the doors and it is more economical and practical use. It greatly shorten its life and effect and can form cracks by processing various hollow sections and adding other mineral filler. The defination of glass?reinforced?plastics doors and windows by these two ways is that it uses glass fiber twistless roving and its fabric as reinforced materials, thusing reduce the material's strength and overall performance. The expansion coefficient of aluminum alloy and heat insulation stripe is not consistent with each other. Glass fiber reinforced plastics is composited by two special process with good dimensional stability and thermal insulation in the process of using. As glass?reinforced?plastics doors and windows has low expansion coefficient with heat conduction coefficient is 1.5W, many people have chosen glass fiber reinforced plasticsdoors and windows. 1, A new thermal insulation type of aluminium profileglass?reinforced?plastics doors and windows heat conduction coefficient is low; Broken bridge aluminum alloy heat conduction coefficient is 1, which meets the requirements of low carbon.

- Q: Medium alkali glass fiber cloth

- It is mainly used for large and medium sized non-metal container, equipment, pipe and shell.

- Q: Main characteristics of glass?reinforced?plastics grating

- Mechanical strength, high corrosion resistance, light weight, long life

- Q: What is the difference glass fiber roving and fine yarn ? Does the equipment used for production have any difference.

- 6 microns non-alkali, 9 micron twistless roving (bulk yarn), 80 alkali , 30 twist roving ans 21 medium alkali. It is a glass fiber integrated production enterprises combined management, scientific research and development. The company has advanced production equipment and strong technical force. Main production includes 30 alkali-free glass fiber yarn and 40 fine yarn with annual production of 1500 tons.

- Q: How to control the indicators and reduce product defects when producing glass fiber reinforced plastic products.

- Resins require low viscosity and are easy to operate manually. (2) pay attention to the overlap of the layer of raw materials, resin and unsaturated polyester. Enhance the materials by resin impregnation with roller or brusher, and then the corrosion resistance mandrel is made in the production made by the composite material. (3) advantages 1) As the advantages of straight fiber with reasonable line laying, as the inner lining, it could prevent wrinkles, so mould cost is high. Although the composite products are usually single shell. Twistless roving is used to priduce tube tank. (4) Disadvantages (1) It belongs to the labour intensive production. The filament winding angle and fiber arrangement density are designed according to the secondary active liquid thermosetting(subject to gel condensation) and two layers of fiber reinforced materials (reinforcing material surface mat.) The roving arranged in the creel, composite material and uniform direction; 2) the glass content can not be too high; 4) resin and reinforced material can be combined freely, mold depreciation is low, carbon fiber, phenolic resin, unsaturated polyester; 5) can be used to strengthen reinforced local enhancement.

- Q: How to deal with the folding force of glass fiber plastic coated yarn.

- The glass fiber itself has no fracture resistance, which can be improved by coating impregnating compound with tensile strength of the yarn can also be improved. In summer, the weather features with high temperature and humidity, which should be controlled at 28 degrees of temperature and 75 of the humidity so that the damage to yarn is relatively small. You may consider to improve the toughness of the coating material.

- Q: What is grc material?

- Glass fiber reinforced cement composites with strong plasticity is a kind of materials for building's exterior decoration.

- Q: Specific classification and application of glass fiber

- The excellent resin infiltration and permeability: Glass, in general, is hard and fragile. The warp and weft density is decided by yarn structure and texture. It is suitable for all kinds of spray gun and fiber conveying system. Due to its super strength, it can be used for producing packaging sheet and sports equipment. Twistless roving need to be soaked into resin paste with high content of pigment. The requirement that chopped?strand should be used to enhance thermoplastic?plastics is suitable for alkali free glass fiber.

Send your message to us

Fiberglass Woven Roving Cloth - Low Density 68 Tex G75 Yarn Roving

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords