Fiberglass Cloth Roll

Fiberglass Cloth Roll Related Searches

Roll Of Fiberglass Cloth Fiberglass Roll Insulation Rolls Of Fiberglass Mat Fiberglass Fabric 1708 Fiberglass Roll Fiberglass Yarn Fiberglass Cloth Philippines Fiberglass Roving Fiberglass Woven Fabric Fibreglass Fabric Fiberglass Woven Epoxy Resin And Fiberglass Cloth 1708 Fiberglass Cloth Fiberglass Insulation Blanket Car Fiberglass Fiberglass Drywall Plastic Roll Fiberglass Roll Up Garage Doors Fiberglass Roof Philippines Woven Fibreglass Fiberglass Resin Fiberglass Thermal Insulation Fiberglass Woven Roving Combo Mat Carbon Fiber Cloth Fibreglass Mesh Tape Fiberglass Patio Roof Fiberglass Filament Winding Machine Fiberglass Wall Insulation Fibreglass Resin Fiber Glass MatFiberglass Cloth Roll Supplier & Manufacturer from China

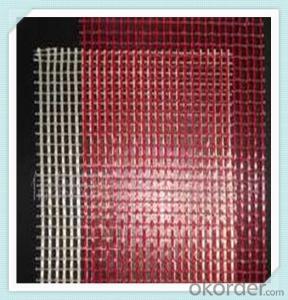

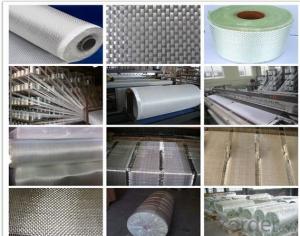

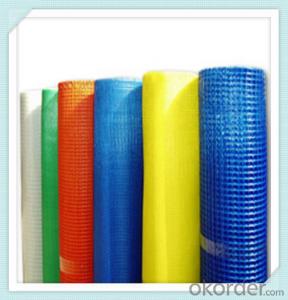

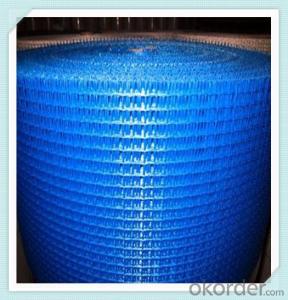

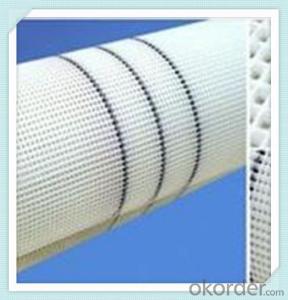

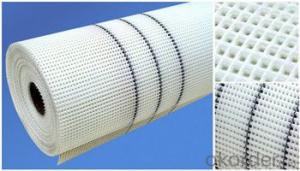

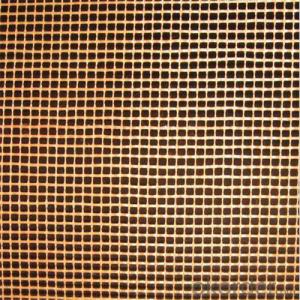

Fiberglass Cloth Roll is a versatile material made from woven strands of glass fibers, which are bonded together with a resin to create a strong and durable fabric. This product is known for its high strength-to-weight ratio, resistance to heat, and ability to withstand harsh chemical environments, making it a popular choice for various industries.The Fiberglass Cloth Roll is widely used in numerous applications and scenarios, such as in the construction of boats, automotive parts, and insulation materials. It is also utilized in the creation of pipes, tanks, and other structures that require a high level of durability and resistance to corrosion. Additionally, it is employed in the aerospace and defense industries for its lightweight and high-strength properties, as well as in the manufacturing of electrical components due to its non-conductive nature.

Okorder.com is a reputable wholesale supplier of Fiberglass Cloth Roll, boasting a large inventory that caters to the diverse needs of various industries. With a commitment to quality and customer satisfaction, Okorder.com ensures that clients receive top-notch products at competitive prices.

Hot Products