Fiberglass Roof Philippines

Fiberglass Roof Philippines Related Searches

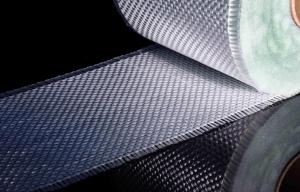

Fiberglass Patio Roof Fiberglass Cloth Philippines Transparent Roof Philippines Fiberglass Roving Fiberglass Roofing Tissue Fiberglass Woven Metal Roofing Philippines Fiberglass Fabric Fiberglass Thermal Insulation Fiberglass Yarn Fiberglass Panels For Roofing Fibreglass Pipes Fiberglass Woven Fabric Fibreglass Fabric Fiberglass French Doors Fiberglass Sheets For Roofing Car Fiberglass Direct Roving Fiberglass Fiberglass Roll Up Garage Doors Fiberglass Drywall Fiberglass Wall Insulation Fiberglass Resin Fiberglass Roll Insulation Fiberglass Mesh Singapore Fiberglass Cloth Roll Fibreglass Resin Resin Fiberglass Fiberglass Insulation Malaysia Woven Fibreglass Fibreglass Mesh TapeFiberglass Roof Philippines Supplier & Manufacturer from China

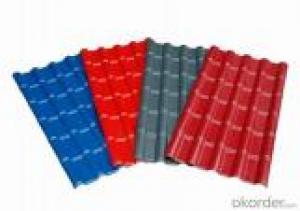

Fiberglass Roof Philippines offers a wide range of fiberglass roofing products that are designed to provide durability, weather resistance, and energy efficiency. These products are made from high-quality materials and are known for their long-lasting performance, making them an ideal choice for various roofing applications. The fiberglass roofing products are available in different styles, colors, and thicknesses, catering to the diverse needs of customers in the Philippines.Fiberglass Roof Philippines products are widely used in residential, commercial, and industrial settings. They are particularly popular for their ability to withstand harsh weather conditions, such as heavy rain, strong winds, and high temperatures. The lightweight nature of these products also makes them easy to install and maintain, reducing the overall cost and effort required for roofing projects. Additionally, fiberglass roofs are known for their energy-saving properties, as they help to reflect sunlight and reduce heat transfer, leading to lower energy consumption and cost savings for homeowners and businesses.

Okorder.com is a leading wholesale supplier of Fiberglass Roof Philippines products, boasting a large inventory that caters to the needs of various customers. As a reputable supplier, Okorder.com ensures that all products meet the highest quality standards and are sourced from reliable manufacturers. This guarantees that customers receive top-notch fiberglass roofing products that are both durable and aesthetically pleasing. By offering competitive prices and efficient shipping, Okorder.com has become a go-to destination for those seeking Fiberglass Roof Philippines products for their construction and renovation projects.

Hot Products