Fiberglass Panels For Roofing

Fiberglass Panels For Roofing Related Searches

Fiberglass Panels For Sale Fiberglass Sheets For Roofing Fiberglass Pool Wall Panels Fiberglass Bathtub Wall Panels Fiberglass Stone Wall Panels Fiber Sheet For Roof Fiberglass Roof Shingles Fiberglass Patio Roof Fiberglass Roving Modular Roof Panels Fiberglass Roofing Tissue Fiberglass Roof Philippines Fiberglass Wall Insulation Foam Panels For Building Attaching Solar Panels To Roof Clear Flat Polycarbonate Roof Panels Felt Paper For Roofing Frp Ceiling Panels Fibreglass Pipes Fiberglass Roll Insulation Fiberglass Roll Up Garage Doors Fiberglass Properties Fiberglass Thermal Insulation Conservatory Plastic Roof Panels Felt Paper Roofing Polystyrene Roof Panels Car Fiberglass Solar Panel On Roof Rack Fiberglass Insulation Blanket Fiberglass DrywallFiberglass Panels For Roofing Supplier & Manufacturer from China

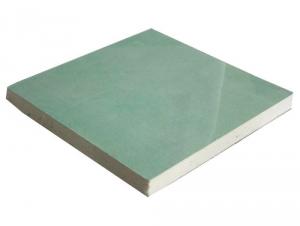

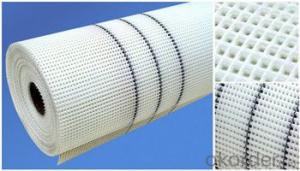

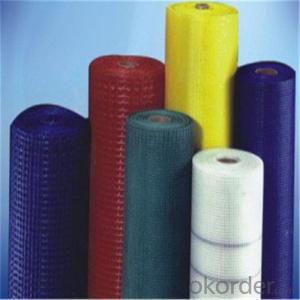

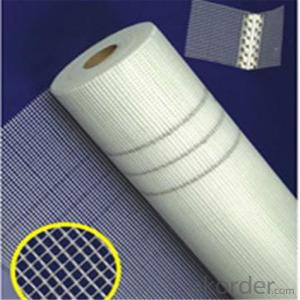

Fiberglass panels for roofing are a popular choice for constructing and maintaining various types of buildings due to their durability, lightweight properties, and resistance to harsh weather conditions. These panels are made from a composite material that combines glass fibers with a resin matrix, resulting in a strong and versatile roofing solution. They are designed to provide long-lasting protection against the elements while maintaining an aesthetically pleasing appearance.Fiberglass panels for roofing are widely used in both residential and commercial settings, offering a range of benefits that make them an ideal choice for a variety of applications. They are commonly used in the construction of garages, carports, sheds, and other outbuildings, as well as for roof replacements and repairs on existing structures. These panels are also suitable for use in agricultural buildings, such as barns and stables, where they can provide protection from the elements while also offering a degree of insulation. Additionally, fiberglass roofing panels are often chosen for their low maintenance requirements and resistance to rot, decay, and insect damage.

Okorder.com is a leading wholesale supplier of fiberglass panels for roofing, offering a vast inventory of high-quality products to meet the needs of customers worldwide. With a commitment to providing exceptional customer service and competitive pricing, Okorder.com ensures that customers can find the perfect fiberglass roofing panels for their specific project requirements. By partnering with reputable manufacturers and maintaining a large stock of products, Okorder.com is able to offer a diverse selection of fiberglass panels for roofing, catering to various styles, sizes, and budgets.

Hot Products