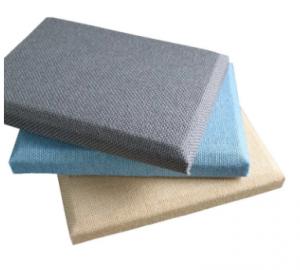

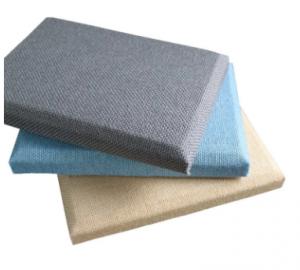

Fiberglass Wall Panel with Low Density

- Loading Port:

- SHANGHAI, CHINA

- Payment Terms:

- TT or L/C

- Min Order Qty:

- -

- Supply Capability:

- 10000 M2 per month m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

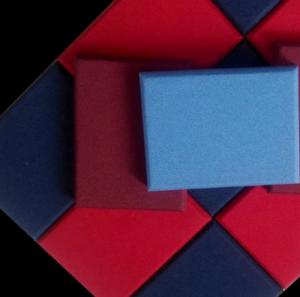

Fiberglass Wall Panel is consist of a high-density fiberglass core and different items and colors of fabrics. The panel has perfect acoustic performance from low to high frequency noise absorbing, and excellent decorative effect. Available in various sizes / edges / fabrics, and for further digital printingon the fabrics.

Technical Data:

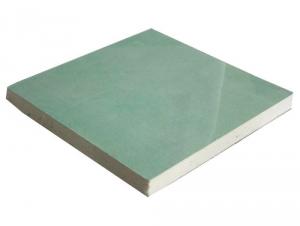

Material: High density dry felt resin bonded fiberglass wool

Facing: Different items and colors of fabrics

Fire-resistant: Class A, non-combustible tested overseas

Humidity: Dimensionally stable with RH up to 95% at 40℃

Environmental: Panels and packing materials are fully recyclable

Main Characteristic:

Excellent sound absorption

Fire-resistant

Moisture resistant

Cleanable and recyclable

Environmentally friendly

Application Areas:

Offices, schools, libraries, hotels, cinemas, theaters, etc., where have special request for sound aborption

- Q: Glass fiber board to do the wall or do ceiling

- Glass fiber board, also known as glass fiberboard, generally used for soft base, outside the package cloth, leather, made of beautiful walls, ceiling decoration. Application is very extensive. With sound-absorbing, sound insulation, heat insulation, environmental protection, flame retardant and so on.

- Q: Glass fiber mesh quality soft and hard for the wall, which is better?

- The softness of the mesh cloth does not depend on the quality of the mesh cloth. Depending on how much glue is applied. Used in the wall, of course, is a lot of glue, and can increase the degree of alkali resistance. Now there is a kind of urine glue, painted out really hard But this is not alkaline.

- Q: Is the interior wall made of fiberglass mesh good or wire mesh?

- If only the local cracks, you can also use ordinary straps paste.

- Q: What is the quality of the light barrier now?

- The partition board includes glass fiber reinforced concrete slab, glass fiber reinforced gypsum hollow slab, steel wire (steel mesh) reinforced concrete slab, light concrete slab, composite sandwich light bar and so on. The full name is the building wall with a light strip, as a general industrial buildings, residential buildings, public works of non-load-bearing wall of the main material. It is a lightweight partition project which is a non-bearing internal wall of a commercial building, a residential building and a public building project with a light partition.

- Q: FRP can be used to make walls

- Glass (FRP), also known as GRP, that is, fiber reinforced plastic, generally refers to the use of glass fiber reinforced unsaturated polyester, epoxy resin and phenolic resin matrix. Reinforced plastic with fiberglass or its products as reinforcing material, called fiberglass reinforced plastic, or titled fiberglass. As a result of the use of different varieties of resin, so there are polyester glass fiber reinforced plastic, epoxy glass fiber reinforced plastic, phenolic glass steel said. Light and hard, non-conductive, high mechanical strength, less recycling, corrosion resistance. Can replace the steel manufacturing machine parts and cars, ship shell and so on.

- Q: What should the overall wardrobe design should have?

- Wardrobe door panels are glass, sheet and other materials, glass thickness of 5mm, the texture of frosted glass, clear glass, cloth glass and embossed glass and other options.

- Q: What is GRC and can I paint it?

- GRC popular understanding of it, refers to the FRP to do the components of profiles. Can be made into any shape, such as sculpture, murals, decorative lines, etc., generally have a good finished product for you to choose. The advantage is high hardness and light weight and the price is not expensive. Is now a large number of decorative materials used. Can be based on your request, do oily or metallic paint, using the basic are spraying process. Another: custom need to open a separate mold costs, so if a small amount of custom, it is more expensive friends.

- Q: Does the wall paint the shear wall need to hang the fibrous web?

- The role of fiber web: Cement concrete for the reticular fiber into the concrete, the concrete mixing process, the fiber optic cable between the horizontal connection can be the concrete's own rubbing and friction play a role in the formation of fiber monofilament or mesh structure fully open, thus To achieve a large number of polypropylene fiber monofilament to play the effect of cracking. Cement concrete special mesh fiber is extremely effective in controlling the plastic shrinkage, shrinkage, temperature change and other factors caused by micro-cracks, to prevent and inhibit the formation and development of cracks. As a new concrete with anti-cracking fiber, concrete with cement concrete mesh fiber is becoming the glass fiber, steel fiber fiber concrete industry research and application of hot

- Q: Want to know the glass fiber production process and production process, the more detailed the better, thank you

- The production of glass fiber is "clay crucible method", "platinum on behalf of the crucible method", "pool kiln" three methods. "Clay crucible method" is the most primitive process, the main raw materials for the waste glass, the process of high energy consumption, poor product quality, is the state out of the prohibition of the process. "Platinum crucible method" is currently widely used in the process, the raw material for the glass ball. "Pool kiln" is the most advanced technology, its raw materials are "pyrophyllite" mainly mineral powder mixture.

- Q: Grc light partition board construction steps is what

- Clean up construction operations In order to ensure the smooth construction of the GRC lightweight partition board, clean up the cleaning parts of the partition board in time and remove the debris from the ceiling, the wall and the mortar blocks protruding from the cylinder, and then rinse the upper part with water Of the floating ash and sand, and dry, and then check the flatness of the site to ensure that the floor of the ground formation, for high and low depression more than 40mm parts should be leveling.

1. Manufacturer Overview

| Location | Jiangsu, China |

| Year Established | 1997 |

| Annual Output Value | Above US$ 10-US$ 50 Million |

| Main Markets | North America South America Eastern Europe Southeast Asia Africa Oceania Mid East Eastern Asia Western Europe |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao |

| Export Percentage | 80%-90% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above5000 square meters |

| No. of Production Lines | Above 4 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average;Low |

Send your message to us

Fiberglass Wall Panel with Low Density

- Loading Port:

- SHANGHAI, CHINA

- Payment Terms:

- TT or L/C

- Min Order Qty:

- -

- Supply Capability:

- 10000 M2 per month m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords